Manganese composite valence crosslinking substance adsorption catalytic material as well as preparation method and application thereof

A technology for adsorption, catalysis and cross-linking, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. through etc. questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

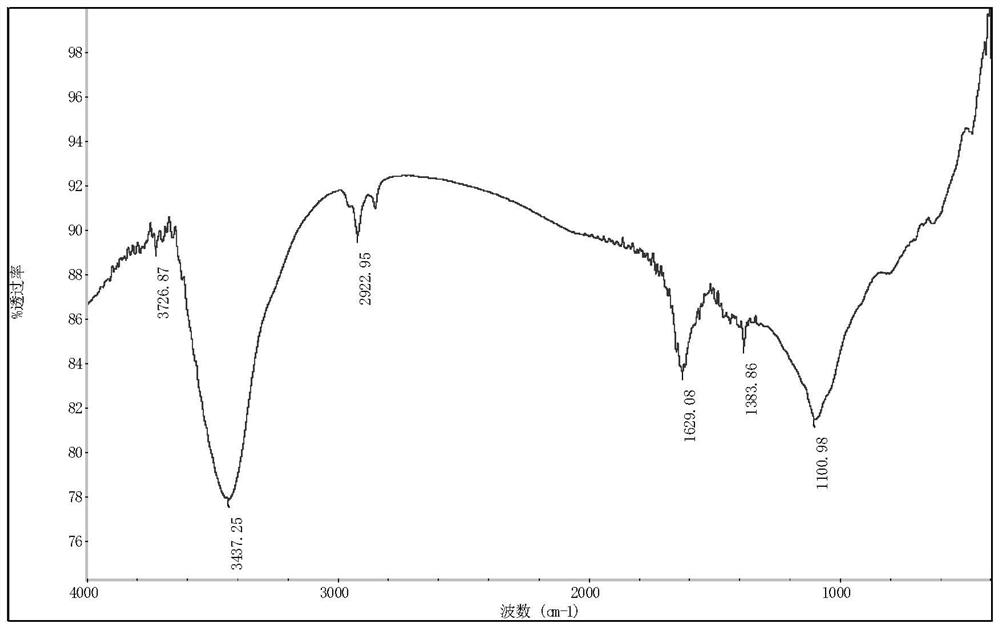

[0024] (1) Preparation of manganese (IV) doped carbon dots:

[0025] In a 100mL hydrothermal kettle, dissolve 18.8g gallic acid (0.1mol) in 50mL hot water, add 0.86g (0.01mol) of MnO 2 , Seal the reaction kettle, heat it to 400°C in a muffle furnace, cool it after 4 hours, take it out, and centrifuge to retain the precipitate, which is Mn(IV) doped carbon dots.

[0026] (2) Preparation of manganese (III) cross-linked montmorillonite powder:

[0027] In a mortar, add 50g of montmorillonite powder, slowly add 10g of Mn(III) acetylacetonate complex (i.e. manganese(III) acetylacetonate) while stirring, finish adding, grind for 5 minutes, and pass solid phase reaction at normal temperature, Prepare Mn(III) cross-linked montmorillonite powder.

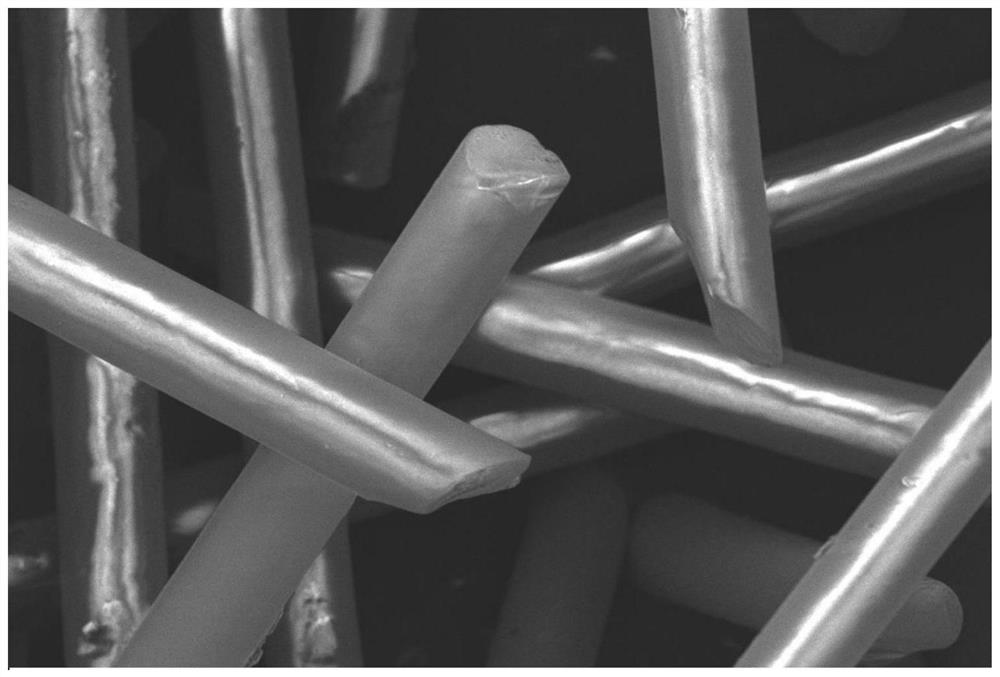

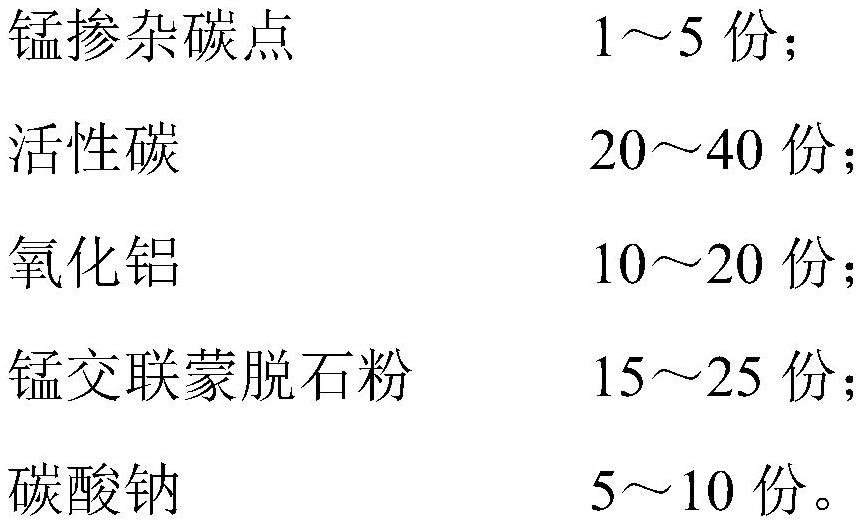

[0028] (3) The preparation method of the adsorption catalytic material of the manganese composite valence state (III / IV) cross-linked product:

[0029] 5 grams of Mn (IV) doped carbon dots and 25 grams of Mn (III) cross-linked montmorillo...

Embodiment 2

[0033] (1) Preparation of manganese (IV) doped carbon dots:

[0034] In a 100mL hydrothermal kettle, dissolve 28.2g gallic acid (0.15mol) in 70mL hot water, add 0.86g (0.01mol) of MnO 2 , Seal the reaction kettle, heat it to 400°C in a muffle furnace, cool it after 4 hours, take it out, and centrifuge to retain the precipitate, which is Mn(IV) doped carbon dots.

[0035] (2) Preparation of manganese (III) cross-linked montmorillonite powder:

[0036] In a mortar, add 50g of montmorillonite powder, slowly add 10g of Mn(III) acetylacetonate complex while stirring, after adding, grind for 10 minutes, and make Mn(III) cross-linked montmorillonite through normal temperature solid phase reaction. De-stone powder.

[0037] (3) The preparation method of the adsorption catalytic material of the manganese composite valence state (III / IV) cross-linked product:

[0038] 5 grams of Mn (IV) doped carbon dots and 20 grams of Mn (III) cross-linked montmorillonite powder prepared by the abo...

Embodiment 3

[0040] (1) Preparation of manganese (IV) doped carbon dots:

[0041] In a 100mL hydrothermal kettle, dissolve 18.8g gallic acid (0.1mol) in 50mL hot water, add 0.86g (0.01mol) of MnO 2 , Seal the reaction kettle, heat it to 700°C in a muffle furnace, cool it after 2 hours, take it out, and centrifuge to retain the precipitate, which is Mn(IV) doped carbon dots.

[0042] (2) Preparation of manganese (III) cross-linked montmorillonite powder:

[0043]In a mortar, add 50g of montmorillonite powder, slowly add 15g of Mn(III) acetylacetonate complex while stirring, after adding, grind for 8 minutes, and make Mn(III) cross-linked montmorillonite through normal temperature solid phase reaction. De-stone powder.

[0044] (3) The preparation method of the adsorption catalytic material of the manganese composite valence state (III / IV) cross-linked product:

[0045] 5 grams of Mn (IV) doped carbon dots and 25 grams of Mn (III) cross-linked montmorillonite powder prepared by the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com