Grain refining stirring device for die steel casting

A technology of grain refinement and stirring device, which is applied in the direction of mixer with rotating stirring device, transportation and packaging, chemical instruments and methods, etc., can solve the problem of reducing the performance of H13 hot work die steel, reducing the service life of the die, alloying elements High content and other problems, to achieve the effect of simple structure, increased fluidity, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

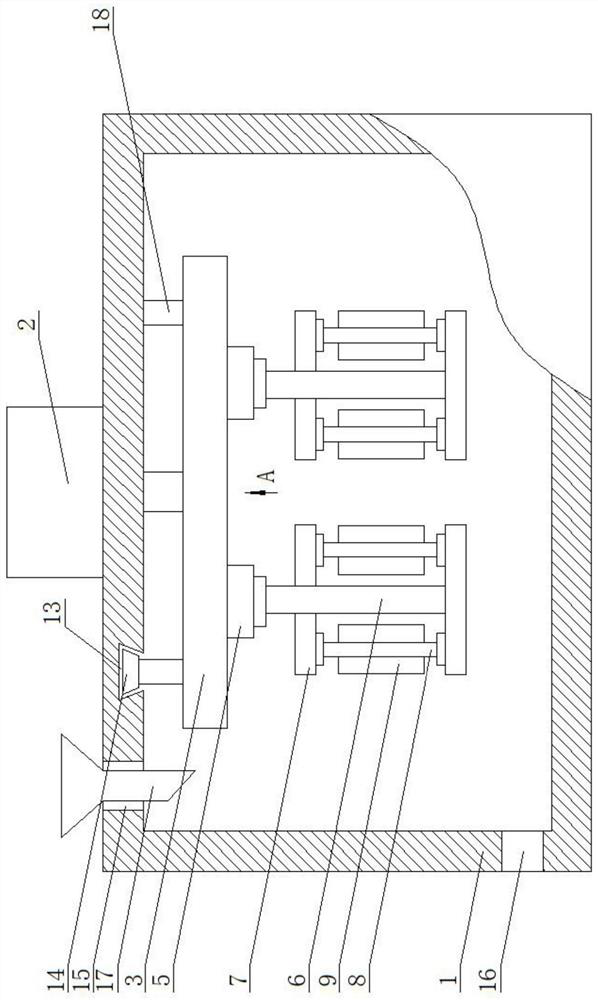

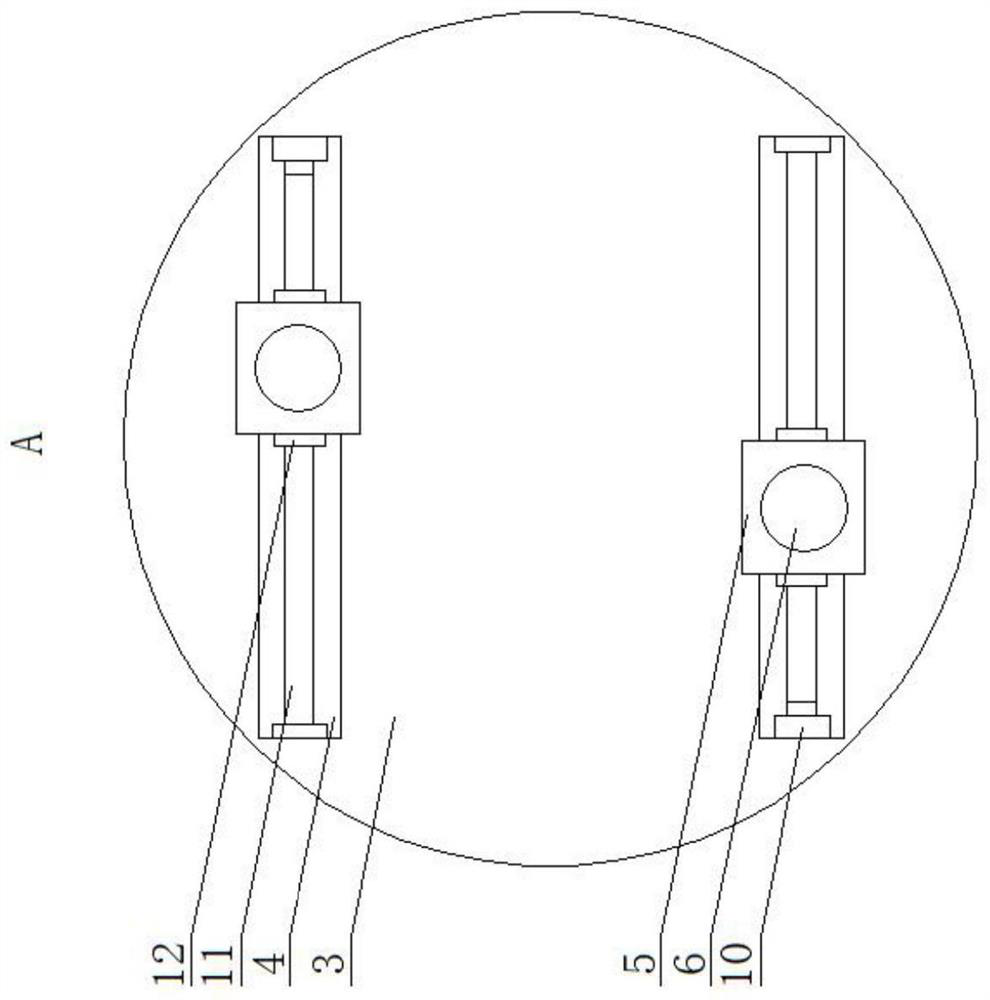

[0028] When using this device, first put molten steel into the box body 1 through the feed port 15, and then make the rotating motor 2 work (forward or reverse), the rotating motor 2 works to drive the turntable to rotate, and the turntable 3 rotates to drive the rotation The shaft 6 rotates, the rotation of the rotating shaft 6 drives the crossbar 7 to rotate, the rotation of the crossbar 7 and the rotating shaft 6 stirs the molten steel, increases the fluidity of the molten steel, and at the same time makes the transmission work, and the transmission drives two sliding blocks 5 The relative movement makes the rotating shaft 6 horizontally displaced while rotating, increasing the stirring of the rotating shaft 6 to the molten steel, further increasing the flow of the molten steel, and at the same time when the horizontal bar 7 rotates, the vertical bar 8 flows in the molten steel The vertical plate 9 is driven to rotate under the active force to further stir the molten steel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com