Novel aluminum model profile, steel bar truss floor support plate mounting system and mounting method

A steel truss and model material technology, which is applied to the steel truss floor deck installation system and the field of new aluminum model materials, can solve problems such as damage to aluminum formwork, difficulty in construction, and impact on aluminum formwork reuse, so as to enhance the firmness of the connection, The effect of low construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

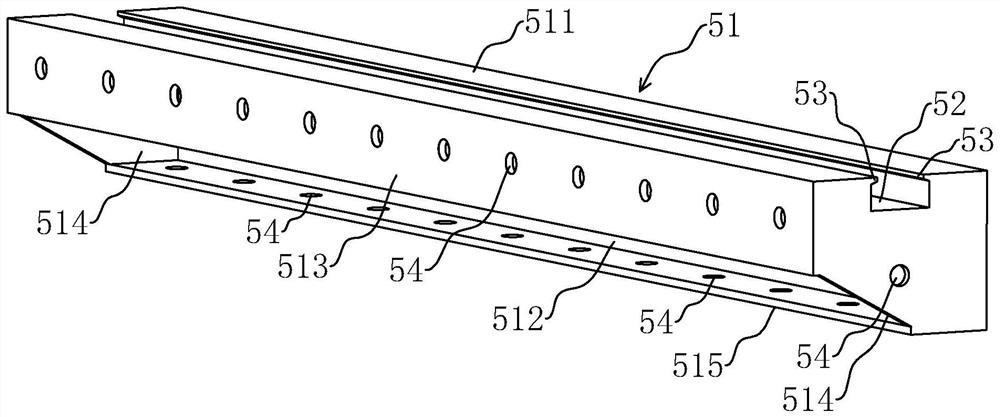

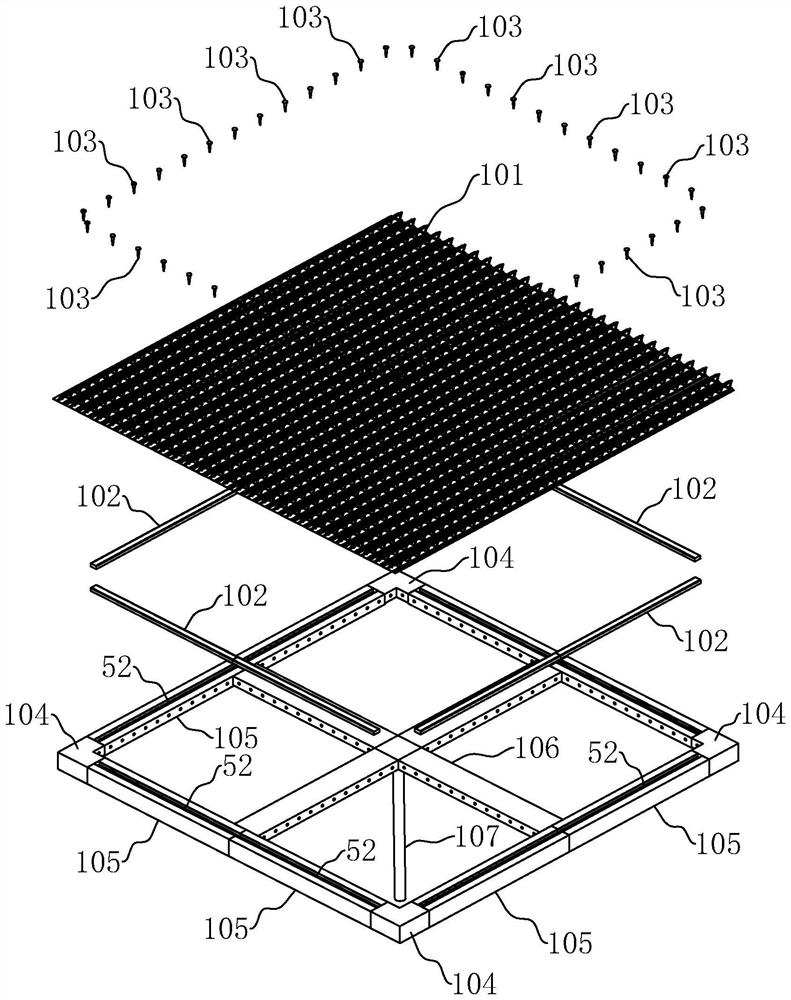

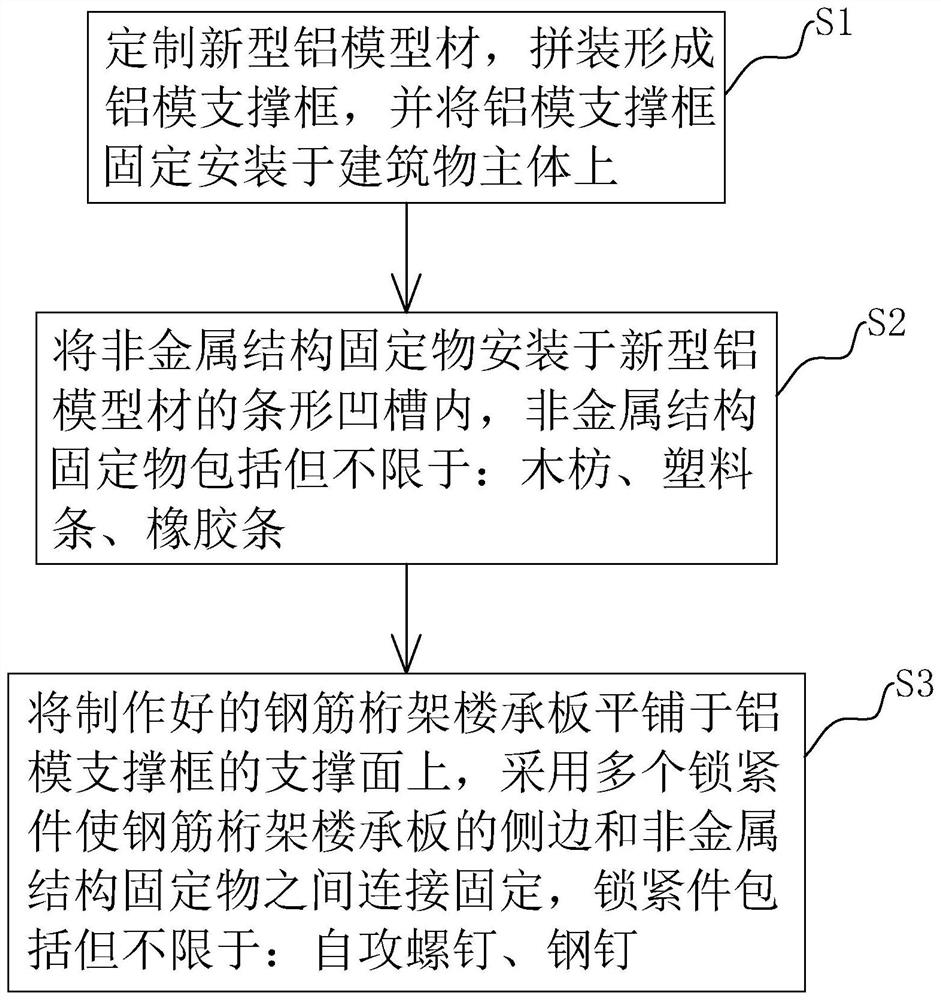

[0038] Embodiment 1 of the present application discloses a new type of aluminum model material. refer to figure 1 and figure 2 , the new aluminum model material 105 includes a profile main body 51, the supporting surface of the profile main body 51 is provided with a strip-shaped groove 52 for installing a non-metallic structural fixture 102, and the entire new aluminum model material 105 is made by an integral molding process .

[0039] Only one strip groove 52 is provided, and the strip groove 52 is arranged along the length direction of the profile main body 51. The cross-section is rectangular, and the cross-section of the corresponding non-metallic structure fixture 102 is also rectangular, thereby facilitating the processing and forming of the strip-shaped groove 52 and the non-metal structure fixture 102, and the strip-shaped groove 52 with two ends penetrating design, It is convenient to insert the non-metal structural fixture 102 laterally from both ends, and it i...

Embodiment 2

[0057] Embodiment 2 of the present application discloses a new type of aluminum model material. refer to figure 2 and Figure 4 , the difference with the novel aluminum model material in embodiment one is:

[0058] There are only a plurality of bar-shaped grooves 52 arranged at even intervals. In this embodiment, the number of bar-shaped grooves 52 is eight, and the bar-shaped grooves 52 are arranged perpendicular to the length direction of the profile main body 51. The bar-shaped grooves The two ends of 52 respectively penetrate to the outer surface and inner surface of the profile main body 51 . At the same time, the two barrier strips 53 at the top opening of the strip-shaped groove 52 are also arranged perpendicular to the length direction of the profile main body 51 .

[0059] The new aluminum model material designed above also has the following predictable technical effects: the strip groove 52 provides a stable installation position for the non-metallic structural f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com