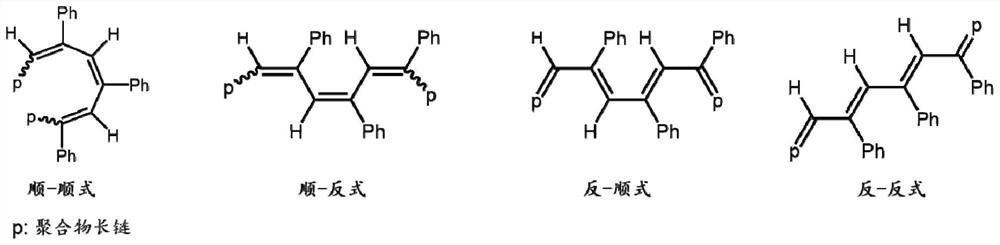

Conjugated conductive polymer modified copper-based catalyst as well as preparation method and application thereof

A conductive polymer and copper-based catalyst technology, applied in the field of nanotechnology and electrochemistry, can solve the problems of complex modification methods and poor hydrophobicity, and achieve the effect of improving hydrophobicity and conductivity, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

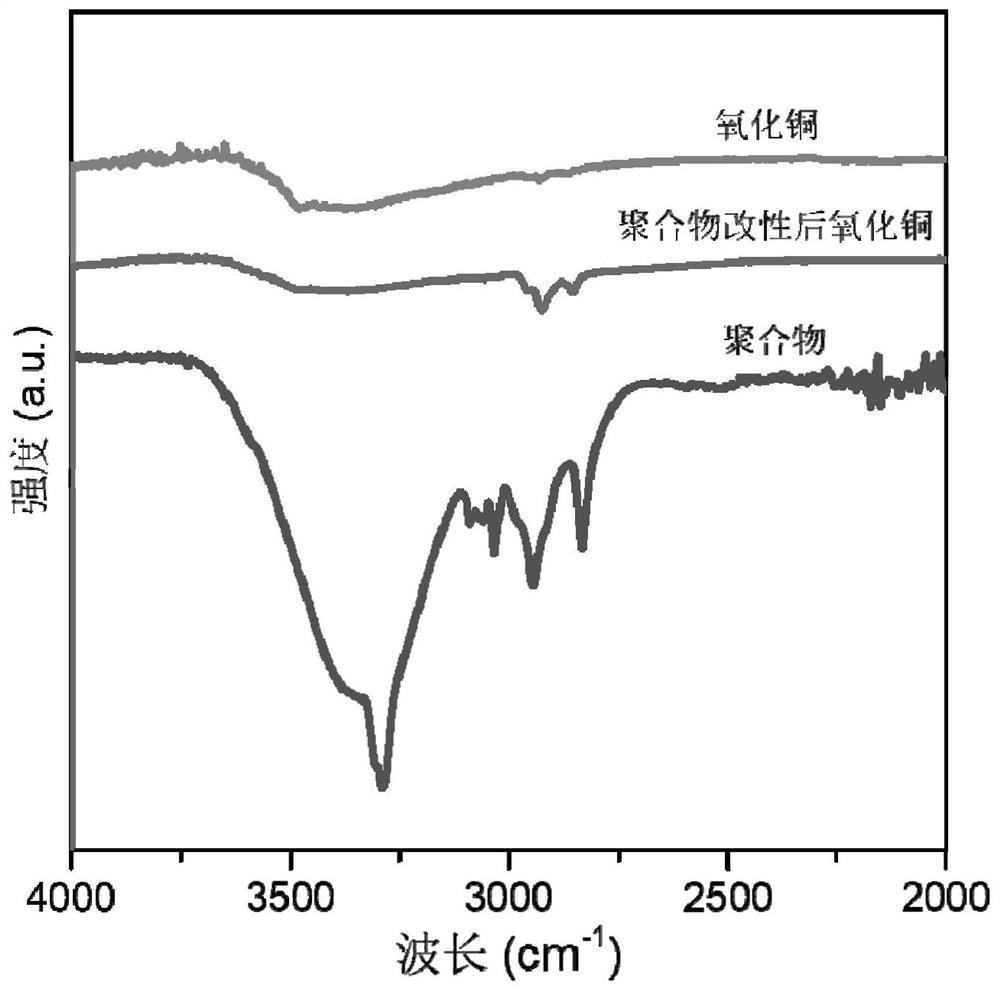

[0051] Preparation of a Conjugated Conductive Polymer Modified Copper-Based Catalyst

[0052] (1) Soak 0.1g of commercial copper powder in acetone solvent and ultrasonically clean it for 6 minutes to remove organic impurities attached to the surface. The ultrasonic frequency is 40kH Z Subsequent transfer to the nitric acid solution of 0.5mol / L for soaking and washing for 3 times, then with 100mL of ultrapure water, the copper powder after the above-mentioned treatment is cleaned;

[0053] (2) transfer the cleaned copper powder in step (1) into a muffle furnace for heating and roasting treatment, the roasting temperature is 500° C., and the roasting treatment time is 3 hours, to obtain a copper oxide-based material with a clean surface and no impurities;

[0054] (3) Grind the copper oxide substrate obtained in step (2) into powder, then disperse in 1 mL of polyphenylene vinylene toluene solution with a concentration of 2 mg / mL, and carry out ultrasonic dispersion treatment at ...

Embodiment 2

[0058] Preparation of a Conjugated Conductive Polymer Modified Copper-Based Catalyst

[0059] (1) Soak 0.1g of commercial copper powder in acetone solvent and ultrasonically clean it for 30 minutes to remove organic impurities attached to the surface. The ultrasonic frequency is 20kH Z Subsequent transfer to the nitric acid solution of 0.5mol / L for soaking and washing for 3 times, then with 100mL of ultrapure water, the copper powder after the above-mentioned treatment is cleaned;

[0060] (2) transfer the cleaned copper powder in step (1) into a muffle furnace for heating and roasting treatment, the roasting temperature is 200° C., and the roasting treatment time is 4 hours, to obtain a copper oxide-based material with a clean surface and no impurities;

[0061] (3) Grind the copper oxide base material obtained in step (2) into powder, then disperse in 1 mL of acetone solution of polyphenylene ether with a concentration of 4 mg / mL, and carry out ultrasonic dispersion treatmen...

Embodiment 3

[0064] Preparation of a Conjugated Conductive Polymer Modified Copper-Based Catalyst

[0065] (1) Soak 0.1g of commercial copper powder in acetone solvent and ultrasonically clean it for 60 minutes to remove organic impurities attached to the surface. The ultrasonic frequency is 10kH Z Subsequent transfer to the nitric acid solution of 0.75mol / L for soaking and washing for 3 times, then with 100mL of ultrapure water, the copper powder after the above-mentioned treatment is cleaned;

[0066] (2) transfer the cleaned copper powder in step (1) into a muffle furnace for heating and roasting treatment, the roasting temperature is 100° C., and the roasting treatment time is 1 h, to obtain a copper oxide-based material with a clean surface and no impurities;

[0067] (3) Grind the copper oxide base material obtained in step (2) into powder, then disperse in 1 mL of polyphenylene vinylene cyclohexane solution with a concentration of 1 mg / mL, and carry out ultrasonic dispersion treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com