Preparation equipment for synthesizing quartz glass powder particles

A technology for synthesizing quartz and glass powder, used in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of long melting time, splashing of debris openings, and efficiency to be improved, to avoid high-temperature flue gas leakage, reduce The effect of stacking raw materials and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

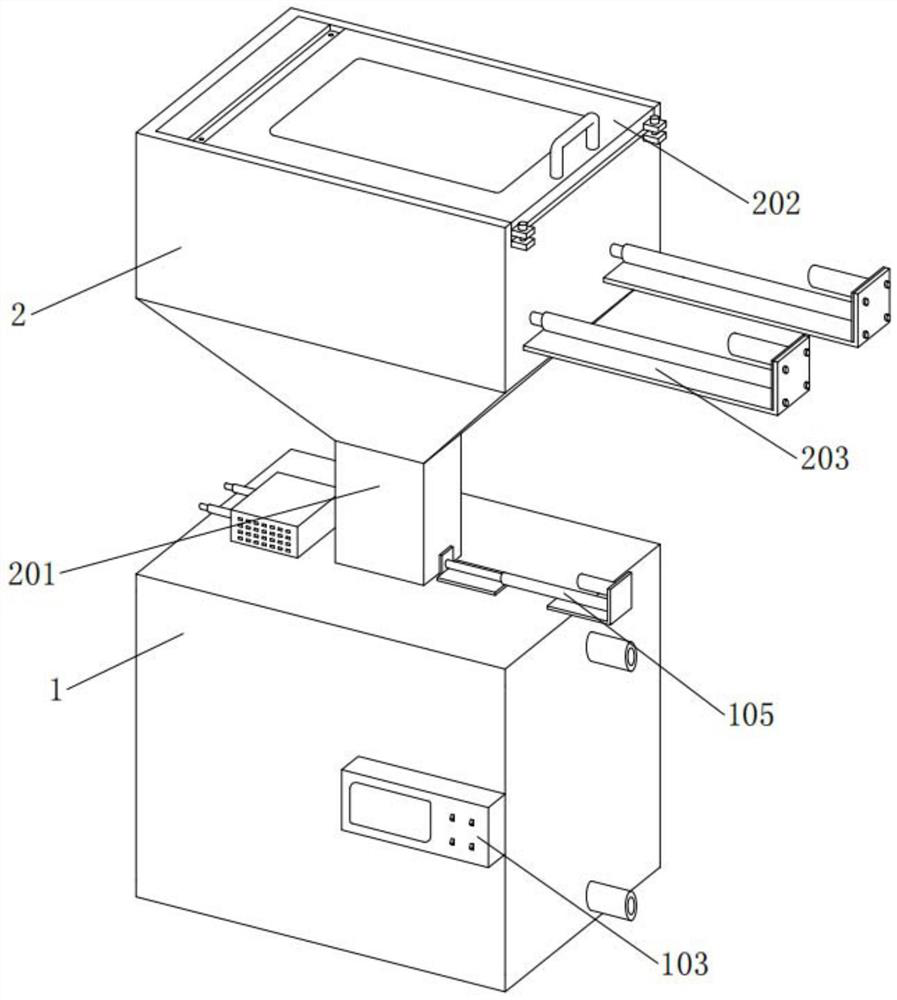

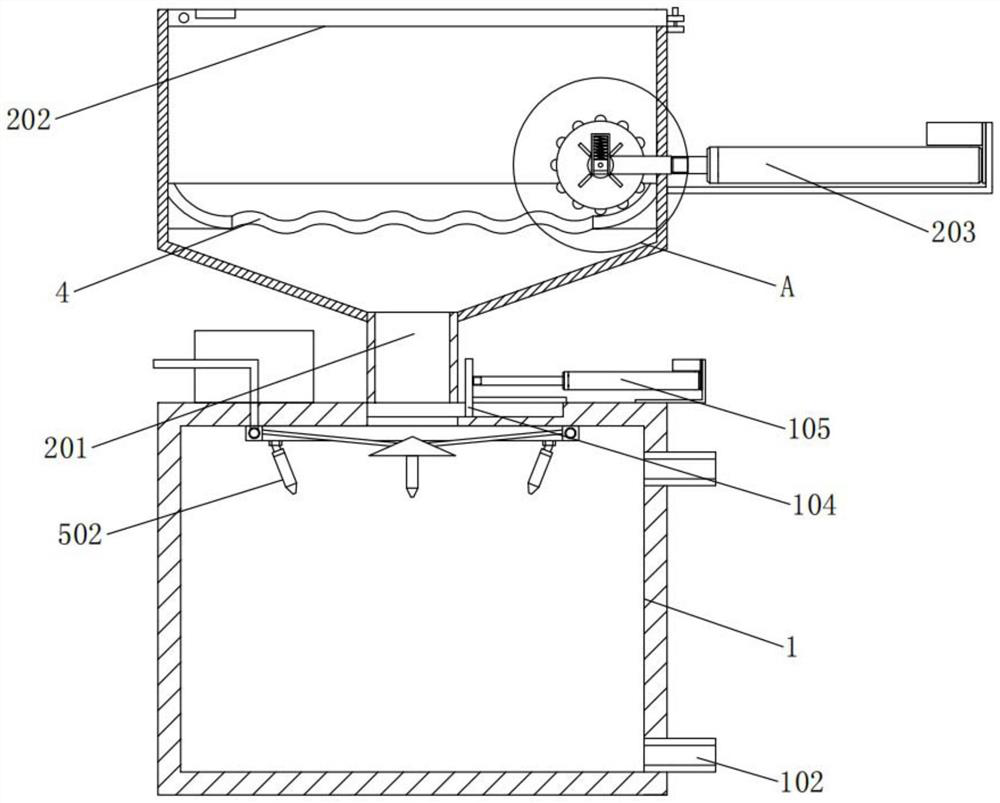

[0041] A preparation device for synthetic quartz glass powder, comprising a box body 1, the box body 1 is a rectangular parallelepiped structure made of fused alumina bricks, the upper right side of the box body 1 is equipped with a smoke exhaust pipe 101, the box body 1 is equipped with a discharge pipe 102 at the lower right side, a controller 103 is installed on the front of the box body 1, and a material inlet is opened on the top of the box body 1;

[0042] The preparation equipment for synthetic quartz glass powder also includes: a feeding hopper 2, which is installed directly above the box body 1, and a connecting pipe 201 is installed between the feeding hopper 2 and the box body 1, and the connecting pipe 201 covers the Above the feed inlet, a box cover 202 is embedded in the position above the right side of the feed hopper 2;

[0043] The top of the feed hopper 2 is covered by the box cover 202, so as to prevent the glass raw materials in the feed hopper 2 from splas...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the feed hopper 2 is an inverted cone, and a pair of electric push rods 203 are fixedly connected to the right side of the feed hopper 2, and the telescopic part of the electric push rod 203 runs through the feed hopper 2 right side wall of

[0046] One end of the electric push rod 203 penetrating through the inner wall of the feed hopper 2 is connected with the rolling roller 3 through the rotating shaft;

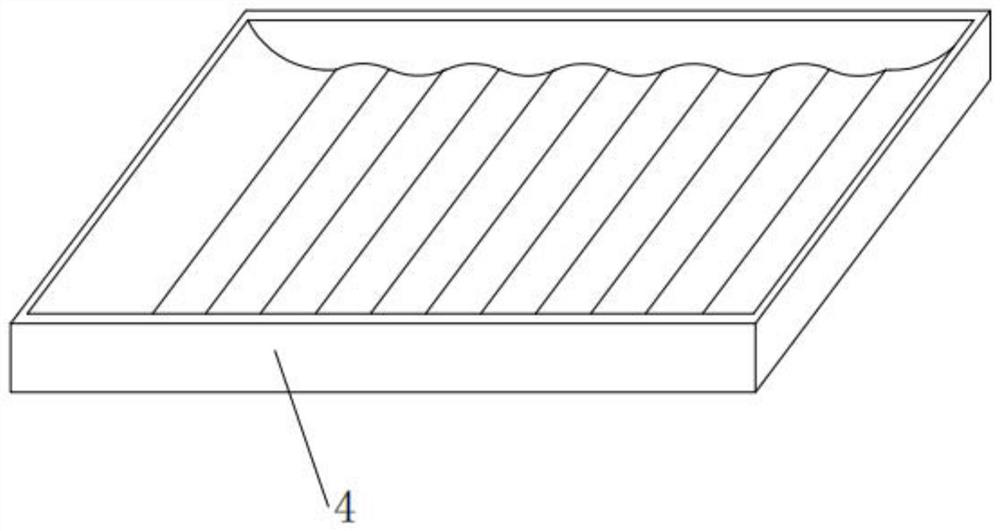

[0047] The inside of the feed hopper 2 is equipped with a horizontally arranged sieve plate 4, and the rolling roller 3 is closely attached to the upper end surface of the sieve plate 4;

[0048] The rolling roller 3 is driven by the electric push rod 1 203 to reciprocate horizontally on the top of the sieve plate 4. During the movement of the rolling roller 3, the glass raw materials can be evenly crushed, and the rolling roller 3 can be dispersed during the movement. The glass raw material on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com