Resource utilization method based on plant fibrous agricultural wastes

A technology of agricultural waste and plant fiber, which is applied in the field of agricultural waste treatment, can solve the problems of surrounding air pollution, foul smell, and affecting the health of surrounding residents, so as to reduce the amount of manual labor, smooth air circulation, and improve biological dryness. The effect of chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

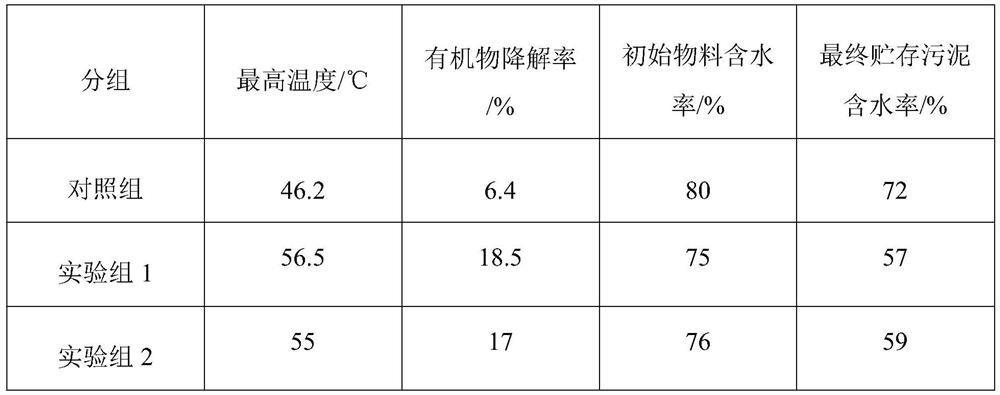

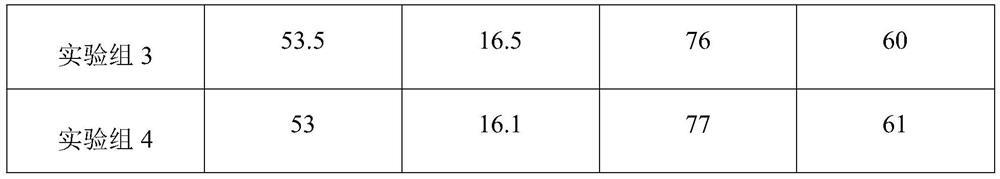

Embodiment 1

[0028] A resource utilization method based on plant fibrous agricultural waste, comprising the following steps: cutting the straw from Heilongjiang into 2-3cm long straw sections for later use, the moisture content of the straw is 10%; the prepared moisture content is 80% , the pH value is 7.1, the volatile solid content is 50%, and the C / N is 4. The storage sludge is used for later use. The storage sludge and rice straw are mixed evenly according to the mass ratio (wet weight) of 5:1, and put into the biological drying Bio-drying is carried out in the reactor; the outer wall of the bio-dryer is tightly wrapped with thermal insulation cotton with a thickness of 15cm to prevent heat loss, and the ventilation pipe is connected to the bottom of the bio-drying reactor, and the cycle of aeration and ventilation is 30 minutes Carry out aeration and ventilation treatment, in each cycle, ventilate for 10 minutes and then close for 20 minutes. This cycle, the aeration and ventilation ra...

Embodiment 2

[0030] A resource utilization method based on plant fibrous agricultural waste, comprising the following steps: cutting wheat straw from Shandong into 2-3 cm long straw sections for later use, the moisture content of the wheat straw is 12%; the prepared moisture content is 82%, the pH value is 7.0, the volatile solid content is 50%, and the C / N is 4.2. The storage sludge is used for later use. The storage sludge and wheat straw are mixed evenly according to the mass ratio (wet weight) of 5:1, and put into Biological drying is carried out in the biological drying reactor; the outer wall of the biological drying reactor is tightly wrapped with thermal insulation cotton with a thickness of 20cm to prevent heat loss. Aeration and ventilation treatment is carried out in the gas ventilation cycle. In each cycle, it is ventilated for 10 minutes and then closed for 25 minutes. In this cycle, the aeration and ventilation rate is 1.2L / (min kg) wet material, fully stirred once every 4 day...

Embodiment 3

[0032] A resource utilization method based on plant fibrous agricultural waste, comprising the following steps: cutting corncobs from Shandong into corncobs with a length of 2 to 3 cm for later use, and the moisture content of the corncobs is 15%; 75%, the pH value is 7.4, the volatile solid content is 55%, and the C / N is 4.1. The storage sludge is used for later use. The storage sludge and corn cob are mixed evenly according to the mass ratio (wet weight) of 7:1, and put into the biological drying reactor for biological drying; the outer wall of the biological drying reactor is tightly wrapped with thermal insulation cotton with a thickness of 10cm to prevent heat loss, and the ventilation pipe is connected to the bottom of the biological drying reactor, and the time is 40min. The aeration and ventilation cycle is carried out for aeration and ventilation treatment. In each cycle, it is ventilated for 15 minutes and then closed for 25 minutes. This cycle is repeated. The aerati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com