High-temperature self-lubricating composite material as well as preparation method and application thereof

A technology of high-temperature self-lubricating and composite materials, which is applied in the field of wear-resistant materials, can solve problems such as pyrolysis, and achieve the effects of low synthesis temperature, promotion of material transfer, and easy activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of Ti 3 SiC 2 The preparation method of / Cu high temperature self-lubricating composite material comprises the following steps:

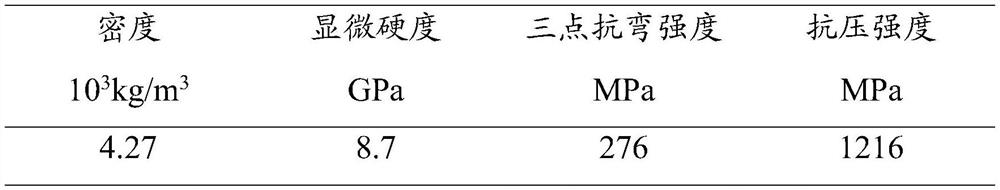

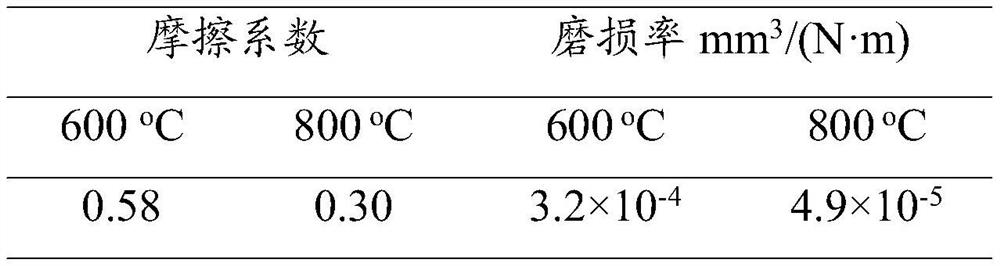

[0026] Ti 3 SiC 2 powder and Cu powder according to the volume ratio V(Ti 3 SiC 2 ): V(Cu)=90:10; mix evenly, put it into a graphite mold, and sinter in a spark plasma sintering system with a vacuum degree of less than 100Pa and a pulse ratio of 36:6. After heating up to 1100°C at a rate of 50°C / min, keep it warm for 5 minutes and then lower it to 1000°C, hold it for 15 minutes. During the sintering process, the sintering pressure is always 35MPa. Get Ti 3 SiC 2 / Cu high temperature self-lubricating composite material.

Embodiment 2

[0028] A kind of Ti 3 SiC 2 The preparation method of / Cu high temperature self-lubricating composite material comprises the following steps:

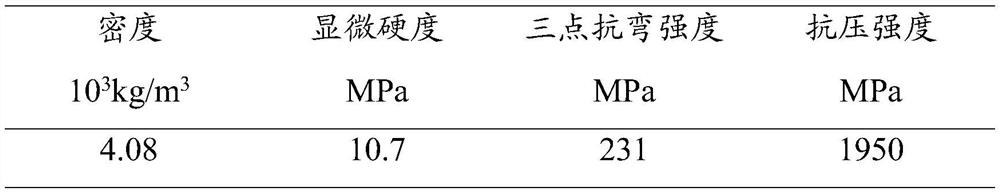

[0029] Ti 3 SiC 2 powder and Cu powder according to the volume ratio V(Ti 3 SiC 2 ): V(Cu)=85:15; mix evenly, put it into a graphite mold, and sinter in a spark plasma sintering system with a vacuum degree of less than 100Pa and a pulse ratio of 36:6. The heating rate was raised to 1050°C at a rate of 50°C / min, then lowered to 1000°C after holding for 5 minutes, and held for 15 minutes. During the sintering process, the sintering pressure was always 35MPa. Ti 3 SiC 2 / Cu high temperature self-lubricating composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com