High-temperature and high-pressure testing system and method used in combustion process

A combustion process, high temperature and high pressure technology, applied in the direction of radiation pyrometry, using directly heat-sensitive electric/magnetic element thermometers, measuring fluid pressure through electromagnetic elements, etc., can solve the problem of inability to completely reproduce the state of boron powder combustion pressure changes , temperature sampling data distortion, delay and other issues, to avoid test data delay, improve sampling accuracy, and improve the effect of connection mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A high-temperature and high-pressure testing system used in the combustion process includes a high-pressure oxygen bomb, a cooling water tank, a temperature measuring device, a pressure measuring device, an ignition device, and a measurement and control system.

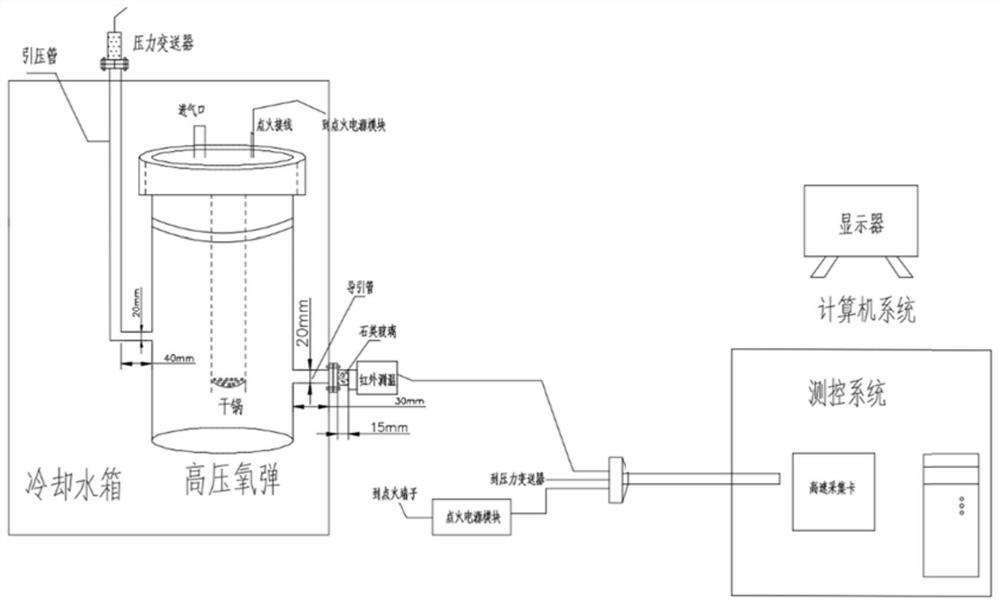

[0054] Such as figure 1 , in this embodiment, the cooling water tank adopts the external protection method of cold water in the water tank to protect the temperature of the oxygen bomb in the experiment. Immerse in cold water for combustion experiments. figure 1 , the air inlet is used to feed oxygen, and the ignition power module is the ignition device described above and below.

[0055] Such as figure 2 , in this embodiment, the method of designing the pressure induction tube on the high pressure oxygen bomb is used to extract and collect the internal pressure of the high pressure oxygen bomb. The pressure induction tube is made of stainless steel, and the pressure induction tube is immersed in the water t...

Embodiment 2

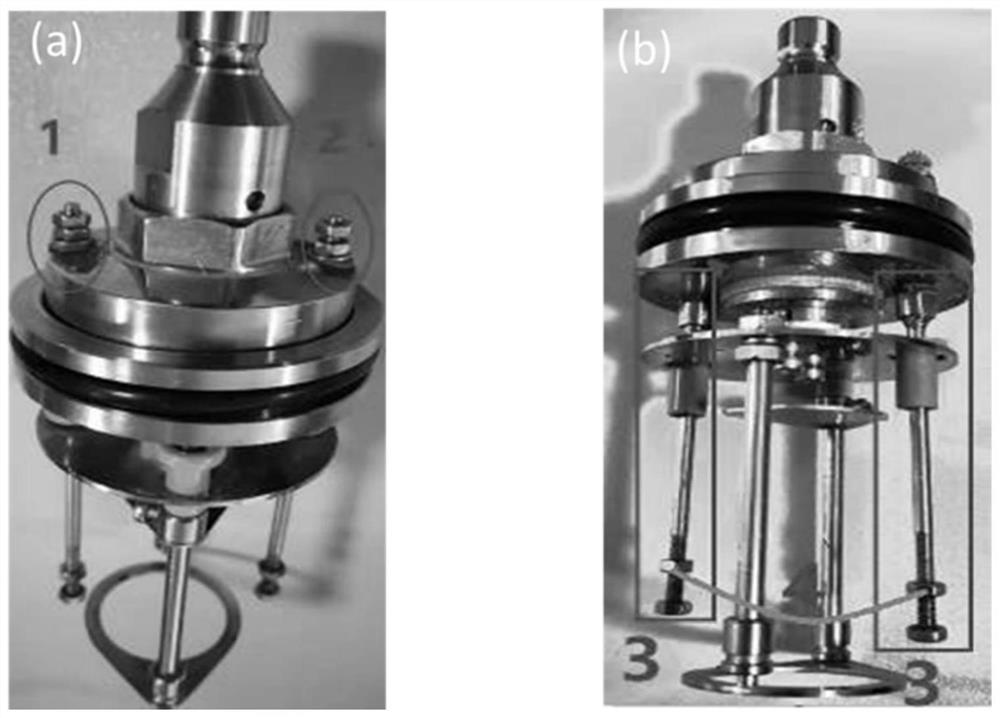

[0062] Such as image 3 , in this embodiment, the temperature measuring device adopts a tungsten-rhenium thermocouple. In order to cooperate with the thermocouple, the internal crucible support of the oxygen bomb is modified, and a stainless steel thermocouple support is added. The height of the thermocouple support is adjustable, and the thermocouple The insertion depth is 2.5-4.0cm from the bottom of the oxygen bomb. image 3 Among them, 1 and 2 are wire posts, connected to the computer acquisition board; 3 is a connecting rod, inside the high pressure oxygen bomb, and the end is connected to a thermocouple wire; 4 is a thermocouple wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com