Production method of cover type intermediate annealing high-grade non-oriented silicon steel 50BW350

A technology of oriented silicon steel and intermediate annealing, applied in the field of agricultural motors, can solve problems such as difficult production and achieve the effect of reducing equipment investment and process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] S1. Steelmaking composition: the contents of C, Si, Mn, P, S, Als, Sb, O, N are: 0.003%, 1.85%, 0.85%, 0.013%, 0.0025%, 0.41%, 0.08%, 0.0018 %, 0.0021%, the balance is Fe and unavoidable inclusions; through the control of the smelting chemical composition of molten steel and the control of inclusions, slabs are obtained after continuous casting;

[0035] S2. The heating temperature of hot rolling is 1130°C; the hot rolling adopts high-temperature final rolling and high-temperature crimping, and the final rolling temperature is 880-890°C; the crimping temperature is 700-720°C;

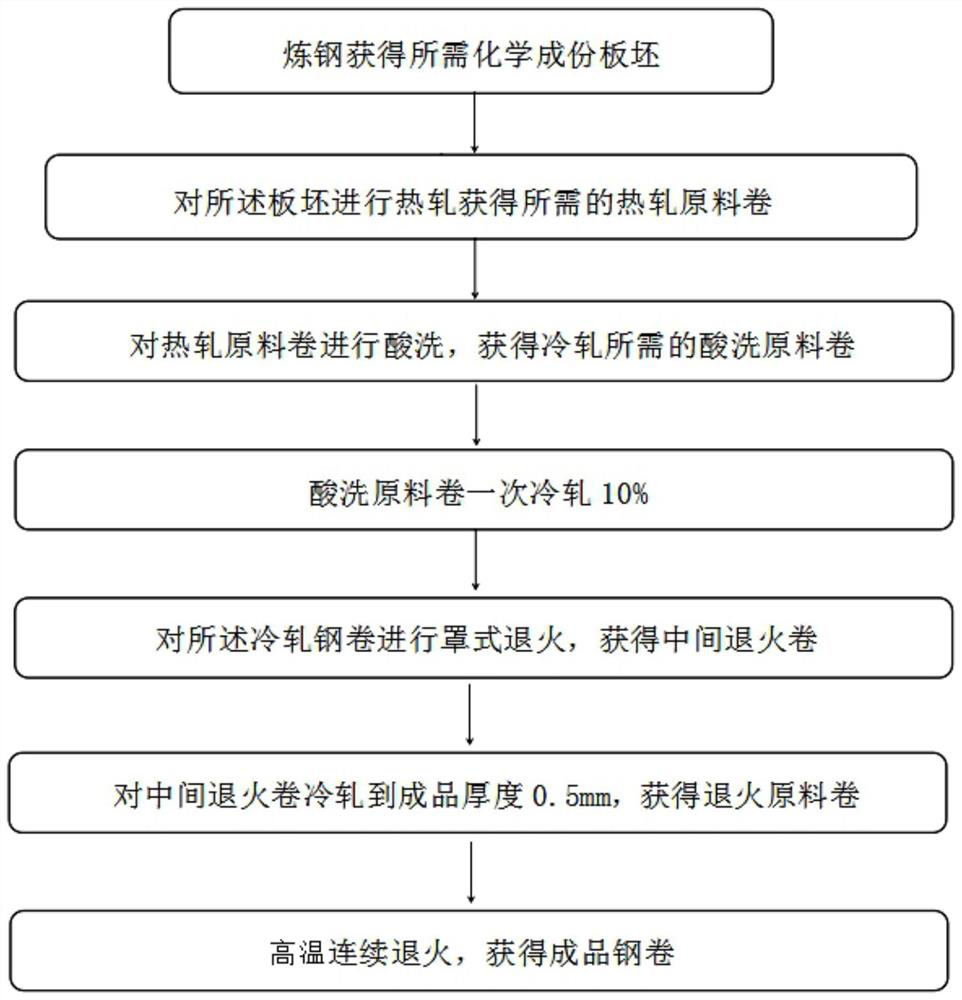

[0036] S3. Cold-rolling process: hot-rolled plate → primary cold-rolling reduction 10% → bell annealing → secondary cold-rolling to 0.5mm → continuous annealing;

[0037] Bell annealing: In order to ensure full recrystallization and grain boundary segregation of Sb elements in the continuous annealing process, the mask annealing temperature is ≥ 730 ℃, and the holding time is more than 30 hours; ...

example 2

[0052] S1. Steelmaking composition: the contents of C, Si, Mn, P, S, Als, Sb, O, N are: 0.003%, 1.85%, 0.85%, 0.013%, 0.0025%, 0.41%, 0.08%, 0.0018 %, 0.0021%, the balance is Fe and unavoidable inclusions; through the control of the smelting chemical composition of molten steel and the control of inclusions, slabs are obtained after continuous casting;

[0053] S2. The heating temperature of hot rolling is 1130°C; the hot rolling adopts high-temperature final rolling and high-temperature crimping, and the final rolling temperature is 880-890°C; the crimping temperature is 700-720°C;

[0054] S3. Cold-rolling process: hot-rolled plate → primary cold-rolling reduction 10% → bell annealing → secondary cold-rolling to 0.5mm → continuous annealing;

[0055] Bell annealing: In order to ensure full recrystallization and grain boundary segregation of Sb elements in the continuous annealing process, the mask annealing temperature is ≥ 730 ℃, and the holding time is more than 30 hours; ...

example 3

[0069] S1. Steelmaking composition: the contents of C, Si, Mn, P, S, Als, Sb, O, N are: 0.003%, 1.85%, 0.85%, 0.013%, 0.0025%, 0.41%, 0.08%, 0.0018 %, 0.0021%, the balance is Fe and unavoidable inclusions; through the control of the smelting chemical composition of molten steel and the control of inclusions, slabs are obtained after continuous casting;

[0070] S2. The heating temperature of hot rolling is 1130°C; the hot rolling adopts high-temperature final rolling and high-temperature crimping, and the final rolling temperature is 880-890°C; the crimping temperature is 700-720°C;

[0071] S3. Cold-rolling process: hot-rolled plate → primary cold-rolling reduction 10% → bell annealing → secondary cold-rolling to 0.5mm → continuous annealing;

[0072] Bell annealing: In order to ensure full recrystallization and grain boundary segregation of Sb elements in the continuous annealing process, the mask annealing temperature is ≥ 730 ℃, and the holding time is more than 30 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com