Application of alumina-loaded Ni catalyst with specific microstructure in preparation of synthesis gas by plasma catalytic methane dry reforming

A methane dry reforming and plasma technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrogen/synthesis gas production, etc., can solve the problem of low selectivity and poor directional conversion ability and other problems, to achieve the effect of increasing the specific surface area and improving the anti-sintering ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

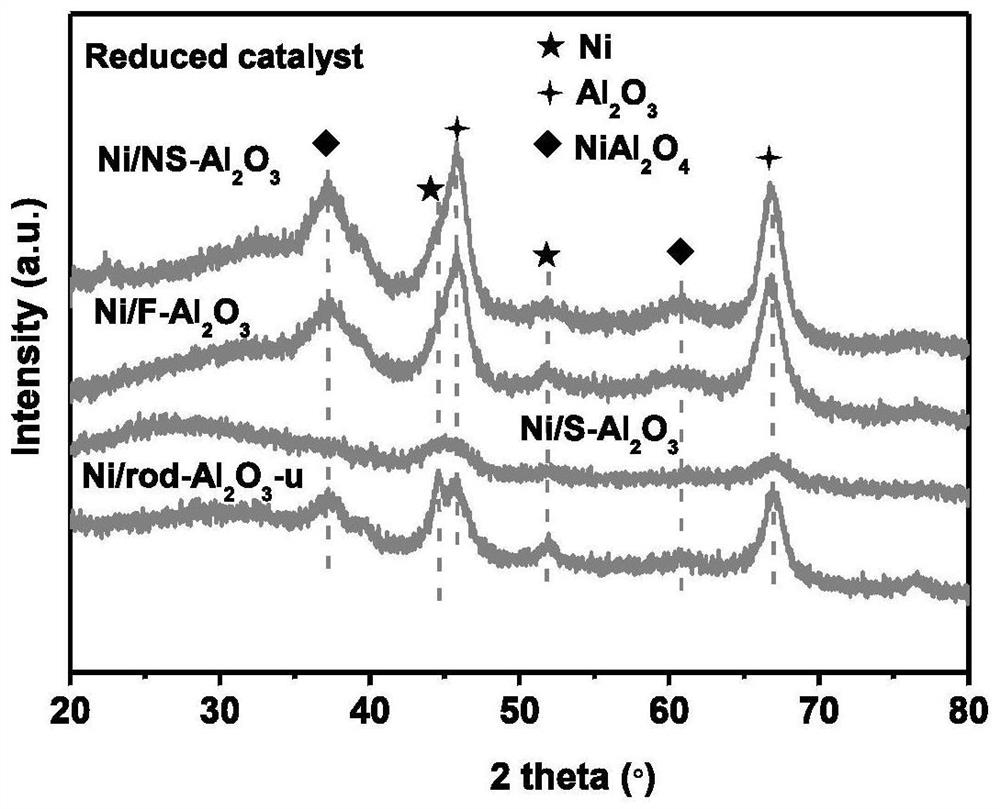

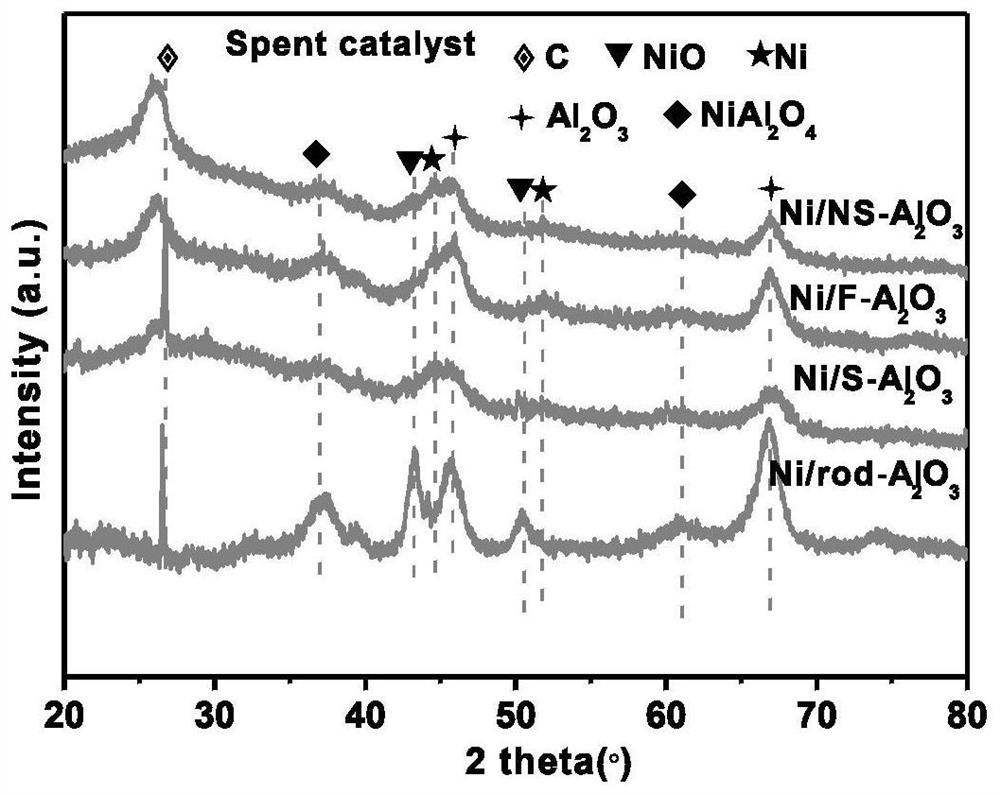

[0042] Catalyst preparation:

[0043] (1) Preparation of nano-flaky alumina (NS-Al 2 o 3 ): 6.0g aluminum nitrate and 9.0g urea dissolved in 120mLH 2 O, stirred at 400r / min for 30min, poured the mixed solution into a 100mL hydrothermal reactor, and reacted at 100°C for 48h. After the reaction, the reactor was naturally cooled to room temperature, filtered and washed three times with water, then the filter cake was freeze-dried at minus 50°C for 72 hours, and finally roasted at 600°C for 2 hours in an air atmosphere.

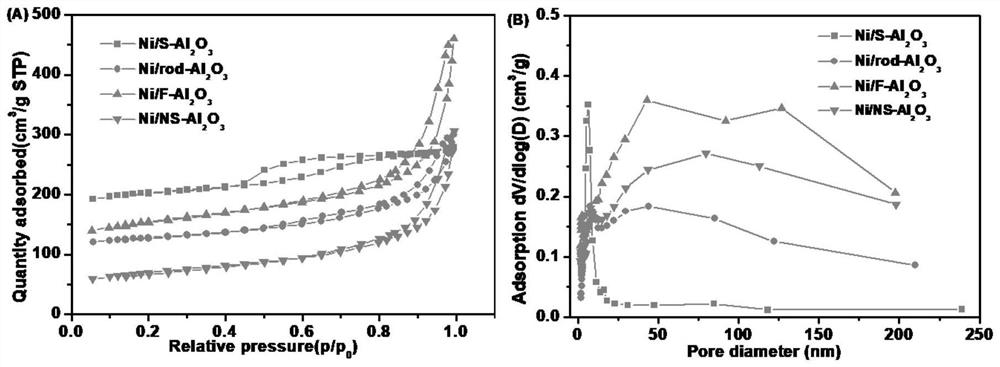

[0044] (2) Preparation of nanosheet-like alumina-supported Ni catalyst (Ni / NS-Al 2 o 3 ): at first the massfraction of Ni is determined as 10%, at first measure the water absorption (2.0mL / g) of nanosheet aluminum oxide, then take by weighing 0.49g nickel nitrate and be dissolved in 2.0mL deionized water to obtain nickel nitrate solution, equal volume impregnation In 1.0g NS-Al 2 o 3 On the carrier, place it at room temperature for 24 hours, then place it ...

Embodiment 2

[0059] Catalyst preparation:

[0060] (1) Preparation of feathery alumina (F-Al 2 o 3 ): 3.7g aluminum nitrate and 7.2g urea dissolved in 60mL H 2 O, stirred at 500 r / min for 30 min, poured the mixed solution into a 100 mL hydrothermal reactor, and reacted at 120 °C for 10 h. After the reaction, the reactor was naturally cooled to room temperature, filtered and washed three times with water, then the filter cake was freeze-dried at minus 50°C for 72 hours, and finally roasted at 600°C for 2 hours in an air atmosphere.

[0061] (2) Preparation of feathery alumina supported Ni catalyst (Ni / F-Al 2 o 3 ): at first the mass fraction of Ni is determined as 10%, and the water absorption (1.6mL / g) of feathery alumina is measured, then 0.49g nickel nitrate is dissolved in 1.6mL deionized water to obtain nickel nitrate solution, equal volume impregnation In 1.0g F-Al 2 o 3 On the carrier, place it at room temperature for 24 hours, then freeze-dry it at minus 50°C for 48 hours, an...

Embodiment 3

[0065] Catalyst preparation:

[0066] (1) Preparation of spherical alumina (S-Al 2 o 3 ): 7.5g aluminum nitrate and 5.0g glucose dissolved in 60mL H 2 O, stirred at 500r / min for 30min, poured the mixed solution into a 100mL hydrothermal reactor, and reacted at 180°C for 20h. After the reaction, the reactor was naturally cooled to room temperature, filtered and washed three times with water, then the filter cake was freeze-dried at minus 50°C for 72 hours, and finally roasted at 600°C for 2 hours in an air atmosphere.

[0067] (2) Preparation of spherical alumina-supported Ni catalyst (Ni / S-Al 2 o 3 ): at first the mass fraction of Ni is determined as 10%, and the water absorption (1.2mL / g) of the spherical alumina is measured, then 0.49g nickel nitrate is dissolved in 1.2mL deionized water to obtain nickel nitrate solution, equal volume impregnated in 1.0g S-Al 2 o 3 On the carrier, place it at room temperature for 24 hours, then place it at minus 50°C for 48 hours and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com