SA-335P11 and SA-240TYPE310S dissimilar steel welding and heat treatment method

A technology of SA-240TYPE310S and SA-335P11, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of preheating temperature, interpass and interlayer temperature, high line energy requirements, and welding and heat treatment methods cannot be completed Problems such as welding work, welding and heat treatment technology are difficult to achieve the effect of protecting the intergranular corrosion resistance, avoiding cold cracks, and protecting the intergranular corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be described in further detail below through specific examples.

[0084] Such as Figure 1 to Figure 10 As shown, a welding and heat treatment method of SA-335 P11 and SA-240TYPE310S dissimilar steels comprises the following steps:

[0085] A. Preparation before welding;

[0086] a1) Determine the execution standards of welding and heat treatment:

[0087] In this embodiment, the implementation standard is:

[0088] ASMEⅨ-2017 "Welding and Brazing Process, Welder, Brazing Worker, Welding and Brazing Operator Evaluation Standard";

[0089] ASMEⅧ-1-2017 "Rules for Construction of Pressure Vessels"

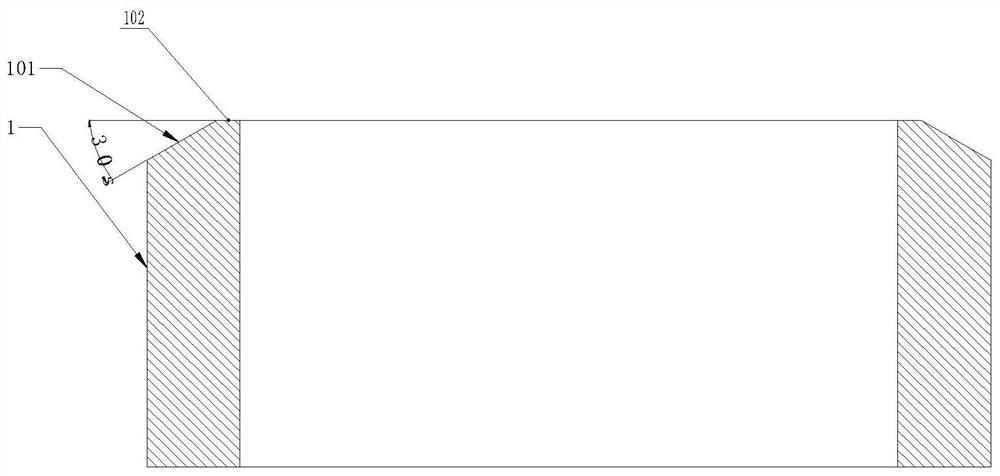

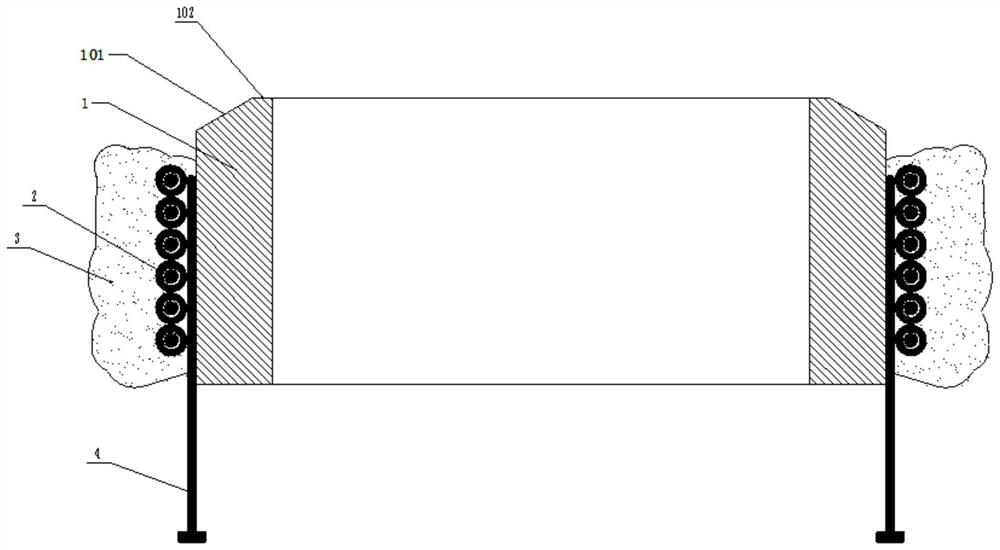

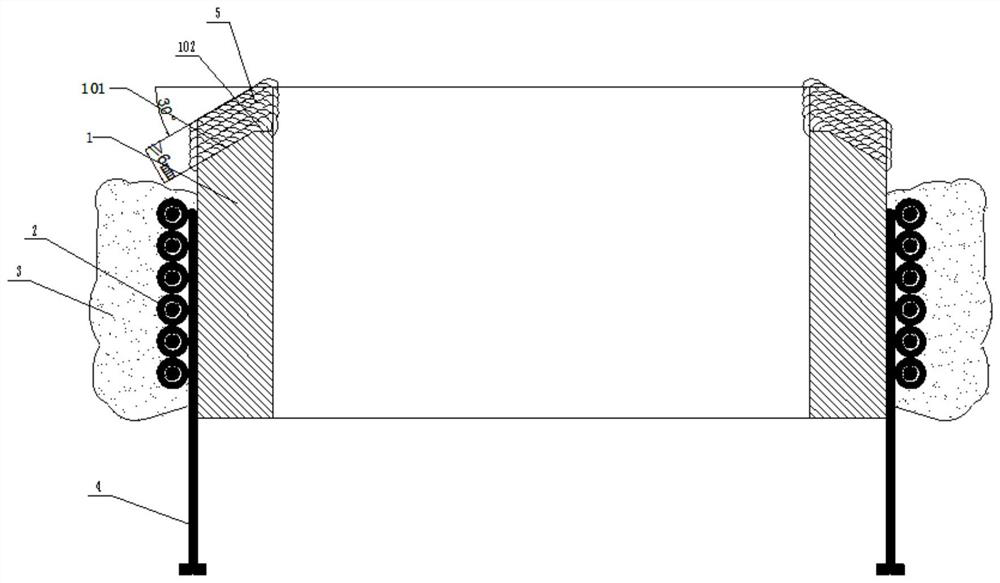

[0090] a2) Check whether the specifications, grades, welding material specifications, grades and gas of the pipes meet the standards; in this embodiment, pipes 1 of SA-335 P11 and SA-240TYPE310Sφ970×28mm are taken as examples, and Table 1 records the specifications of pipes 1 and Technical parameters of welding consumables;

[0091] s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com