Air heat exchanger and method for producing same and electronic structure equipped therewith

A technology of air heat exchanger and heat exchange plate, applied in the direction of heat exchange equipment, indirect heat exchanger, heat exchanger type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] At the outset, it should be pointed out that the same parts are provided with the same reference signs or the same component designations in the differently described embodiments, and that the disclosure content contained in the entire description can be transferred to the same parts with the same reference signs or the same component names. . Furthermore, the positional specifications selected in the description, such as eg top, bottom, side, etc., refer to the directly described and shown figures and can be transferred to the new position in the event of a change of position.

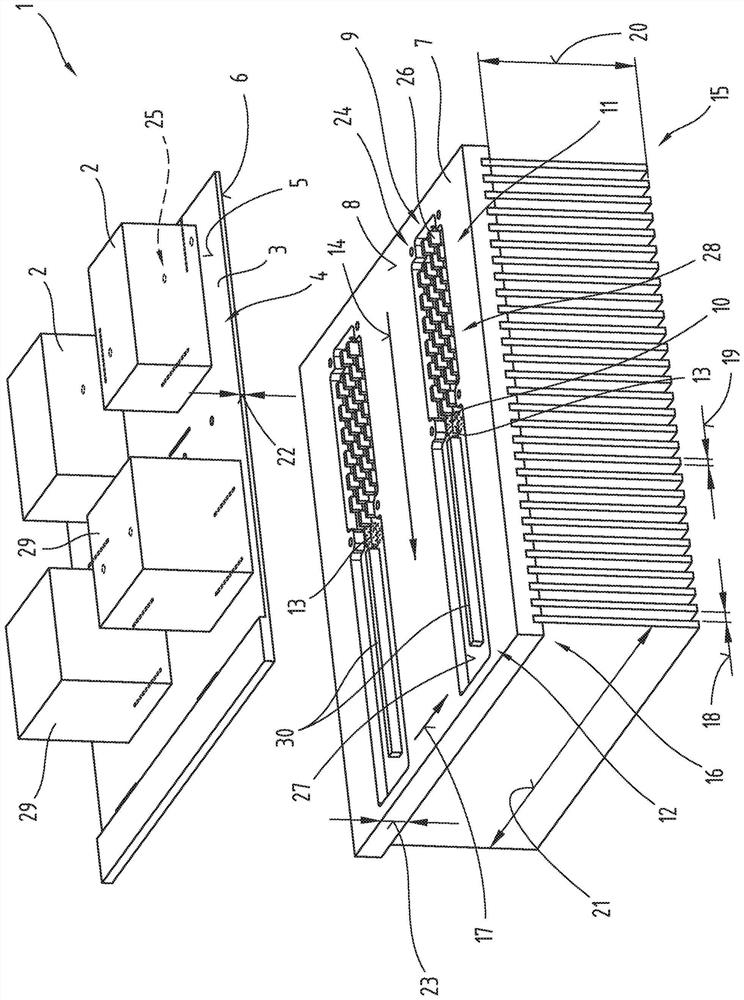

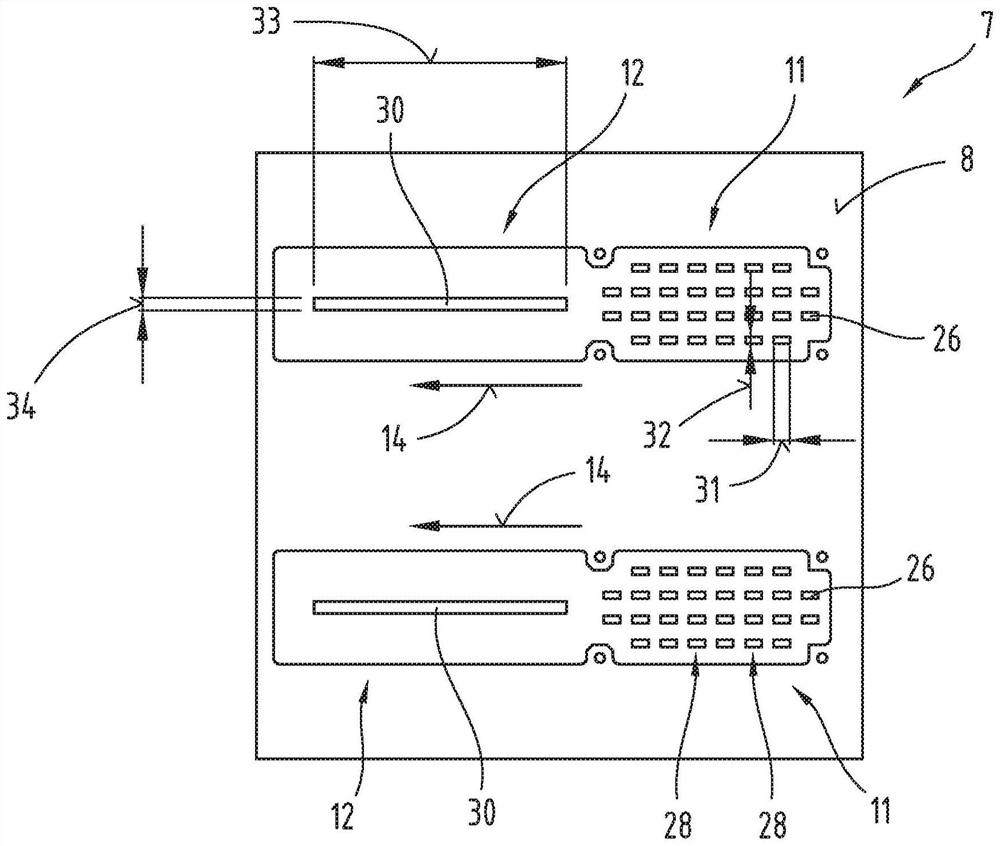

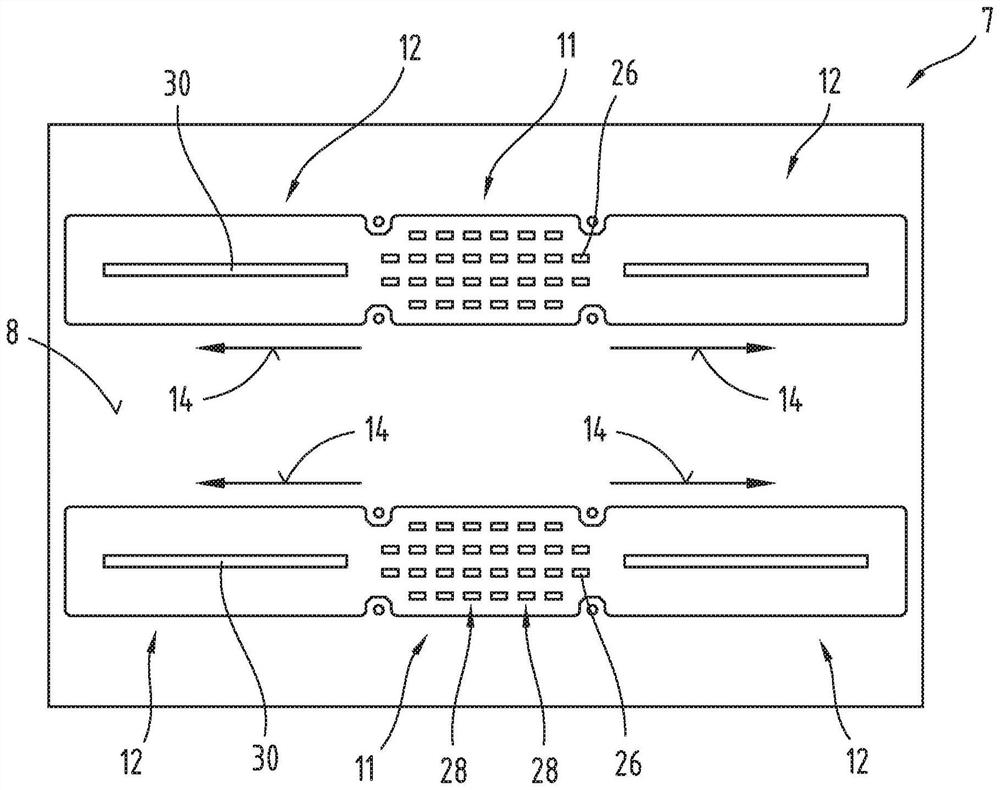

[0080] figure 1 A perspective view of a first exemplary embodiment of an air heat exchanger 1 for cooling power electronics components 2 is shown. Such a power electronic component 2 to be cooled can be, for example, a bipolar transistor with an insulated gate electrode. The air heat exchanger 1 includes a carrier plate 3 which includes a receiving area 4 for receiving power electronics compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com