Monocrystal ternary positive electrode material as well as preparation method and application thereof

A positive electrode material and single crystal technology, applied in the field of single crystal ternary positive electrode materials and their preparation, can solve the problems of high content of doping elements, increased DCR, low material capacity, etc., and achieve high energy density, low residual lithium on the surface, Reduce the effect of surface side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

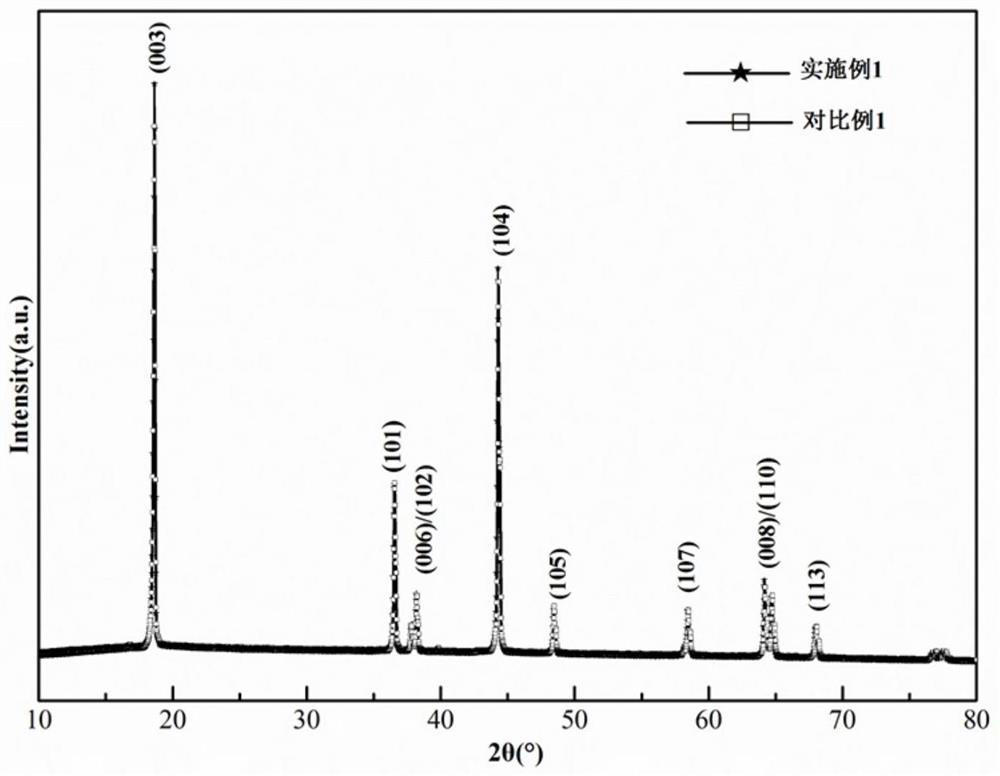

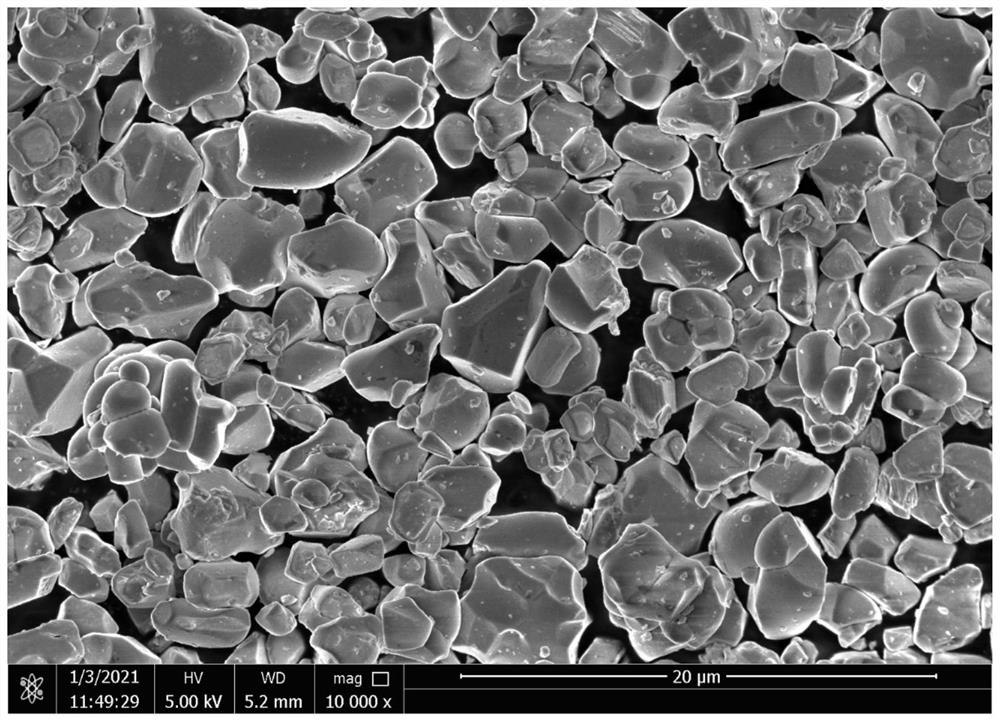

[0054] The single crystal ternary cathode material of the present embodiment has a chemical formula of LiNi 0.596 co 0.05 mn 0.35 m 0.004 o 2 @Li 2 NO 4 ; where M is Zr and W; N is Zr, Al and W; the average particle size of single crystal particles is 1.5-3μm, and the specific surface area is 0.4-0.8cm 2 / g.

[0055] The preparation method of the single crystal ternary cathode material of this embodiment, the specific steps are as follows:

[0056] (1) NiSO 4 、CoSO 4 , MnSO 4 According to the Ni:Co:Mn molar ratio of 0.60:0.05:0.35, a mixed solution with a total metal ion concentration of 1.6mol / L was prepared, and then a 10mol / L NaOH solution was prepared;

[0057] (2) Pass the mixed solution into the reactor, then feed the NaOH solution and the ammonia solution into the reactor and stir for 70 hours, adjust the reaction temperature to 70°C, and the stirring speed to 500r / min, and keep the pH in the reactor at 9.5-12.0, filter, wash with water, and vacuum-dry at 120...

Embodiment 2

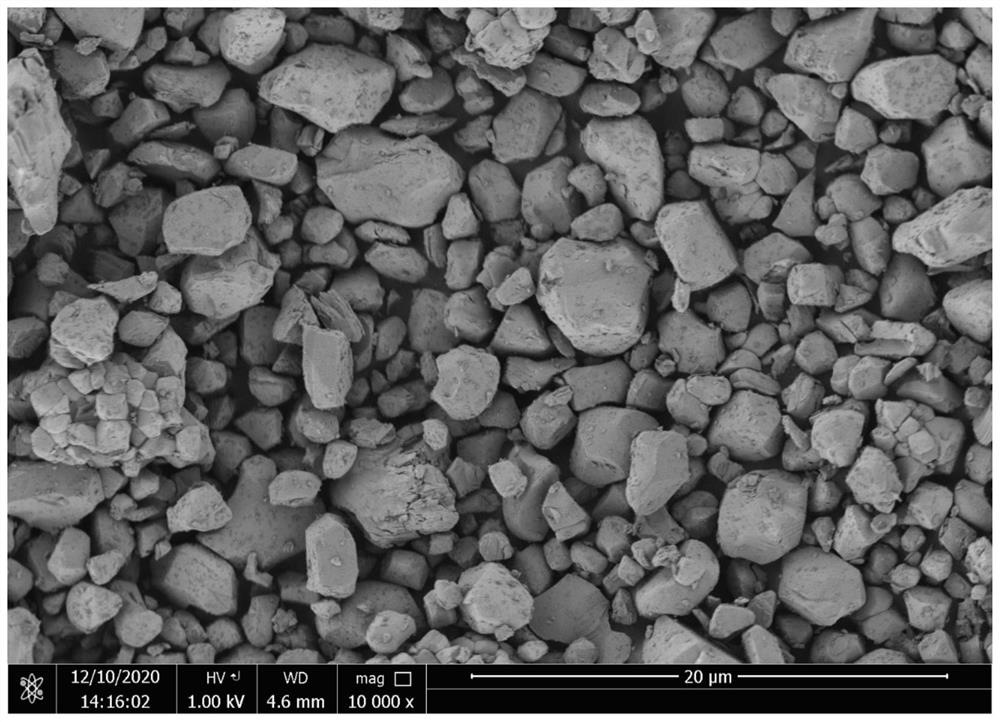

[0065] The single crystal ternary cathode material of the present embodiment has a chemical formula of LiNi 0.799 co 0.1 mn 0.1 m 0.001 o 2 @Li 2 NO 4 ; where M is Zr and W; N is Zr, Al and W; the average particle size of single crystal particles is 1.5-3μm, and the specific surface area is 0.4-0.8cm 2 / g.

[0066] The preparation method of the single crystal ternary cathode material of this embodiment, the specific steps are as follows:

[0067] (1) NiSO 4 、CoSO 4 , MnSO 4 According to the Ni:Co:Mn molar ratio of 0.80:0.10:0.10, a mixed solution with a total metal ion concentration of 1.6mol / L was prepared, and then a 10mol / L NaOH solution was prepared;

[0068](2) Pass the mixed solution into the reactor, then feed the NaOH solution and the ammonia solution into the reactor and stir for 70 hours, adjust the reaction temperature to 70°C, and the stirring speed to 500r / min, and keep the pH in the reactor at 10. After filtering and washing with water, vacuum-dry at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com