Thermoelectromagnetic refrigeration device and preparation method thereof

An electromagnetic and device technology, which is applied in the field of thermoelectric refrigeration devices and their preparation, can solve the problems that traditional thermoelectric device processing methods and integration technologies are no longer applicable, so as to ensure the molding effect and thermomagnetic performance, optimize the sintering process, and ensure the heat dissipation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

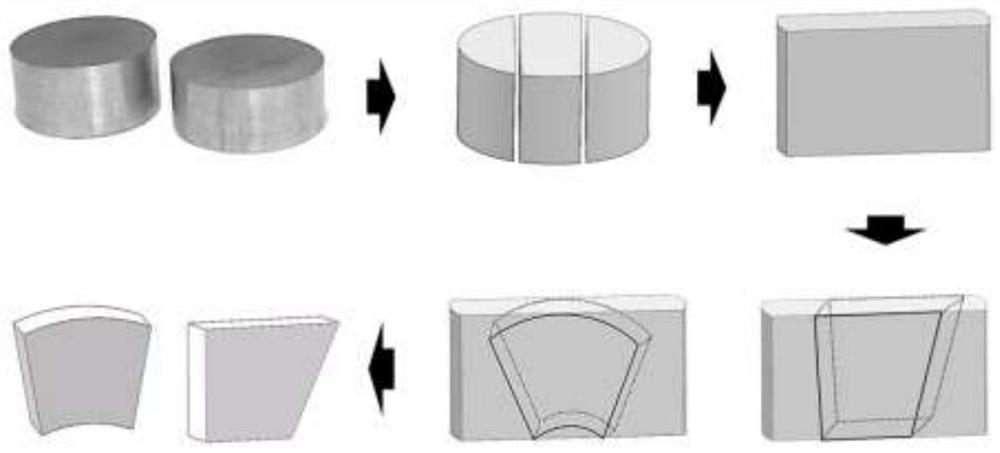

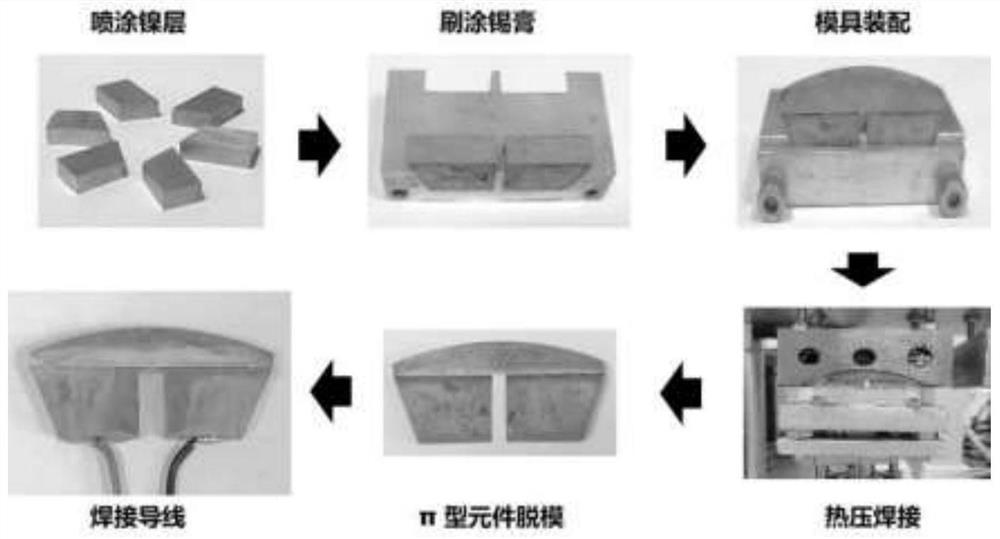

[0051] A thermo-electromagnetic energy conversion all-solid-state refrigeration device, the preparation method of which comprises the following steps:

[0052] 1) Preparation of thermomagnetic materials:

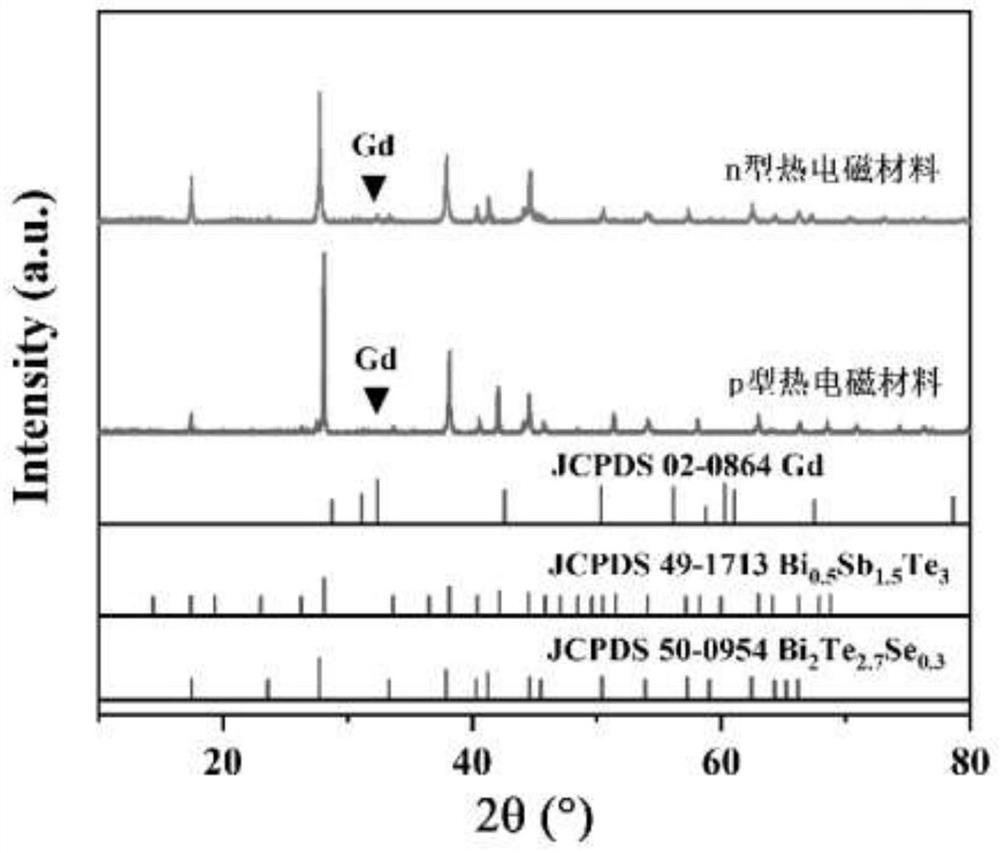

[0053] Using Bi powder, Te powder and Sb powder as raw materials respectively, p-type bismuth telluride (Bi 0.5 Te 3 Sb 1.5 ) and n-type bismuth telluride (Bi 2 Te 0.3 Se 2.7 ) raw materials;

[0054] Mix the weighed raw material powder evenly, vacuum seal the tube and place it in a swing furnace for heat preservation at 650°C for 2 hours to obtain n-type bismuth telluride solid solution alloy and p-type bismuth telluride solid solution alloy;

[0055] The obtained type bismuth telluride solid solution alloy and p-type bismuth telluride solid solution alloy were respectively placed in a pulling furnace for purification, wherein the set temperature was 630°C, and the pulling speed was 15mm / h, to obtain n-type and p-type tellurium respectively Bismuth based crystal rod;...

Embodiment 2

[0068] A thermo-electromagnetic energy conversion all-solid-state refrigeration device, the preparation method of which comprises the following steps:

[0069] 1) Preparation of thermomagnetic materials:

[0070] Using Bi powder, Te powder and Sb powder as raw materials respectively, p-type bismuth telluride (Bi 0.5 Te 3 Sb 1.5 ) and n-type bismuth telluride (Bi 2 Te 0.3 Se 2.7 ) raw materials;

[0071] Mix the weighed raw material powder evenly, vacuum seal the tube and place it in a swing furnace for heat preservation at 650°C for 2 hours to obtain n-type bismuth telluride solid solution alloy and p-type bismuth telluride solid solution alloy;

[0072] The obtained n-type bismuth telluride solid solution alloy and p-type bismuth telluride solid solution alloy were respectively placed in a pulling furnace for purification, wherein the set temperature was 630°C, and the pulling speed was 15mm / h, respectively to obtain n-type and p-type Bismuth telluride-based crystal ro...

Embodiment 3

[0084] A thermo-electromagnetic energy conversion all-solid-state refrigeration device, the preparation method of which comprises the following steps:

[0085] 1) Preparation of thermomagnetic materials:

[0086] Using Bi powder, Te powder and Sb powder as raw materials respectively, p-type bismuth telluride (Bi 0.5 Te 3 Sb 1.5 ) and n-type bismuth telluride (Bi 2 Te 0.3 Se 2.7 ) raw materials;

[0087] Mix the weighed raw material powder evenly, vacuum seal the tube and place it in a swing furnace for heat preservation at 650°C for 2 hours to obtain n-type bismuth telluride solid solution alloy and p-type bismuth telluride solid solution alloy;

[0088] The obtained n-type bismuth telluride solid solution alloy and p-type bismuth telluride solid solution alloy were respectively placed in a pulling furnace for purification, wherein the set temperature was 630°C, and the pulling speed was 15mm / h, respectively to obtain n-type and p-type Bismuth telluride-based crystal ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com