Cobalt molybdate-based Z-type photo-anode material and high-temperature solid-phase preparation method and application thereof

A cobalt molybdate-based, high-temperature solid-phase technology is applied to building thermal insulation materials, buildings, building components, etc., and can solve problems such as unsatisfactory protection effects, achieve high-efficiency photocathode protection, simple preparation methods, and good protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

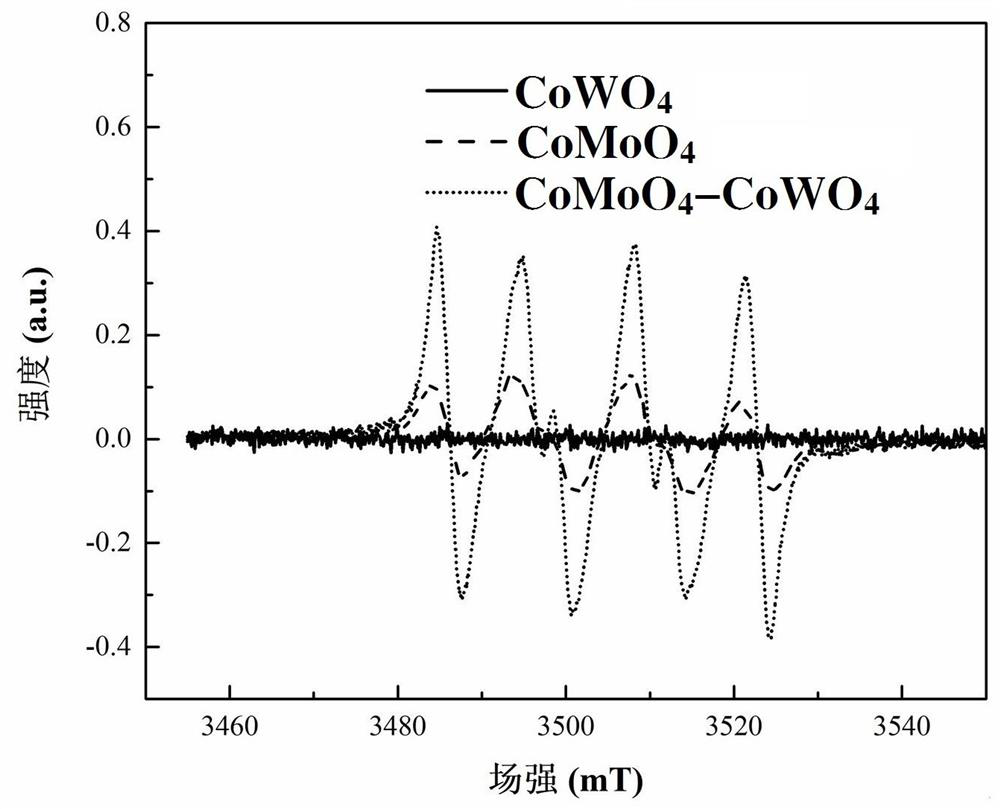

[0028] The present invention aims at the problem that the photoanode materials currently used for photocathode protection have an unsatisfactory protection effect on marine construction projects, and provides a high-temperature solid-phase preparation method for a cobalt molybdate-based Z-type photoanode material, comprising the following steps : After mixing and grinding tungsten-containing compound, molybdenum-containing compound and cobalt-containing compound, roasting to obtain the cobalt molybdate-based Z-type photoanode material. Among them, grinding helps to fully contact the crystal faces of tungsten-containing compounds, molybdenum-containing compounds and cobalt-containing compounds, and nucleation reactions occur at the interfaces at high temperatures.

[0029] This is because the CoMoO in the cobalt molybdate-based Z-type photoanode material prepared by a high-temperature solid-phase preparation method 4 with CoWO 4 With a matching band structure, CoMoO 4 has a l...

Embodiment 1

[0040] 1. The cobalt molybdate-based Z-type (CoMoO 4 -CoWO 4 ) The photoanode material is prepared according to the method comprising the following steps:

[0041] (1) Put 10mmol of tungsten oxide, 500mmol of molybdenum oxide and 510mmol of cobalt oxide into a mortar and grind for 5min to obtain a precursor mixture;

[0042] (2) The precursor mixture prepared in the above step (1) was roasted at 700°C for 12 hours to obtain the cobalt molybdate-based Z-type (CoMoO 4 -CoWO 4 ) photoanode material.

[0043] 2. CoMoO 4 Preparation of photoanode materials: with the above-mentioned cobalt molybdate-based Z-type (CoMoO 4 -CoWO 4 ) The difference in the preparation method of the photoanode material is only that: the step of adding tungsten oxide is omitted, which will not be repeated here.

[0044] 3. CoWO 4 Preparation of photoanode materials: with the above-mentioned cobalt molybdate-based Z-type (CoMoO 4 -CoWO 4 ) The difference in the preparation method of the photoanod...

Embodiment 2

[0048] 1. The cobalt molybdate-based Z-type (CoMoO 4 -CoWO 4 ) The photoanode material is prepared according to the method comprising the following steps:

[0049] (1) Put 500mmol of tungsten nitrate, 10mmol of molybdenum nitrate and 510mmol of cobalt nitrate into a mortar and grind for 5min to obtain the precursor mixture;

[0050] (2) The precursor mixture prepared in the above step (1) was roasted at 1500°C for 3 hours to obtain the cobalt molybdate-based Z-type (CoMoO 4 -CoWO 4 ) photoanode material.

[0051] 2. CoWO 4 Preparation of photoanode materials: with the above-mentioned cobalt molybdate-based Z-type (CoMoO 4 -CoWO 4 ) The difference in the preparation method of the photoanode material is only that the step of adding molybdenum nitrate is omitted, and will not be repeated here.

[0052] 3. Under intermittent light, the CoWO obtained in Example 2 4 and CoMoO 4 -CoWO 4 The current-time curve of the photoanode material is tested, such as figure 2 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com