Vegetable oil-based polymer, composition and preparation method thereof

A vegetable oil-based and vegetable oil technology, applied in botany equipment and methods, plant growth regulators, chemicals for biological control, etc., can solve the problem of reducing the amount of oil separation in preparation storage, natural environment and food hazards, and not using commercial In order to improve physical stability, reduce the loss of liquid medicine, and reduce the evaporation of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

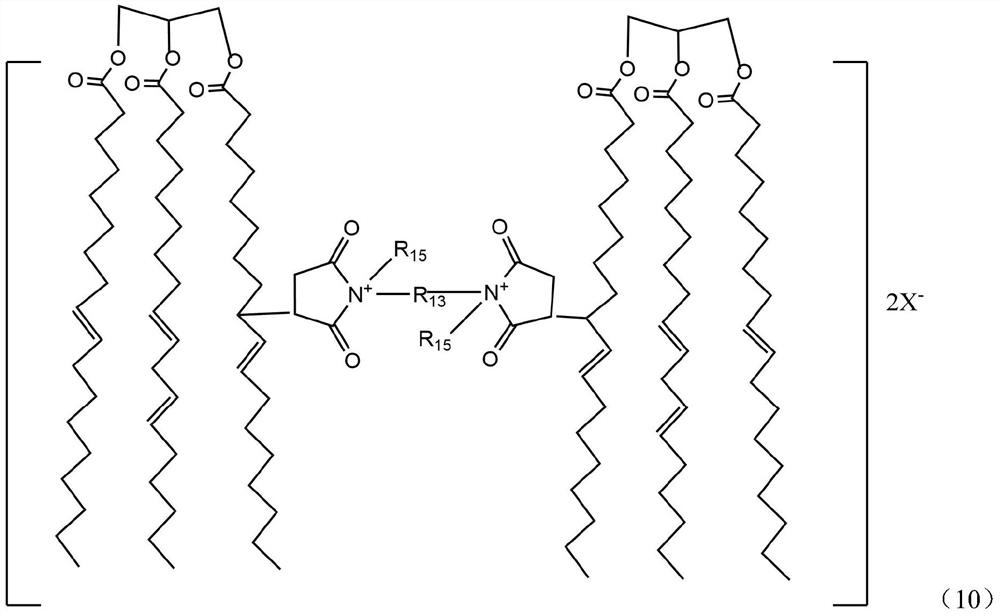

[0089]Add 860g of refined rapeseed oil and 45.28g of maleic anhydride into a four-neck flask, mix and stir for 30 minutes, protect with nitrogen, and raise the temperature to the set temperature of 205°C (the actual temperature will fluctuate by ±5°C during the reaction process) and react for 7h. Chromatography detects that the content of maleic anhydride is 1-2%, and the reaction is completed to obtain maleic anhydride soybean oil. The unreacted maleic anhydride is removed by heating and vacuuming. The set temperature of heating and vacuuming is 112°C (the actual temperature will fluctuate by ±3°C during the reaction process), the vacuum degree is 0.05-0.065Mpa, and the time is 0.6h , and use a condensing device to recover for standby to obtain active polymerizable monomer 1A.

Embodiment 1-1

[0091] Add 3.1g of ethylenediamine and 103.1g of rapeseed oil into a four-necked flask, and add 100g of the above-mentioned maleic anhydrided rapeseed oil dropwise at a temperature of 77°C (the actual temperature may fluctuate by ±3°C during the process) , the dropping time is 30 minutes. After the dropwise addition, vacuum degassing is carried out. The set temperature of vacuum degassing is 152°C (the actual temperature will fluctuate by ±3°C during the reaction process), the degassing time is 6h, and the amine value is 28mgKOH / g, after obtaining the vegetable oil-based polymer with an effective content of 50%; at 72°C (the actual temperature will have a fluctuation of ±3°C during the process), 3.87g of methyl chloride is introduced, and the reaction time is 2.5h; Chloromethane to obtain the quaternized vegetable oil-based polymer 1B using vegetable oil as a solvent.

Embodiment 1-2

[0093] Under the condition of a set temperature of 63°C (the actual temperature may vary within 62-65°C), 40g of the 50% quaternized vegetable oil-based polymer and 60g of the composite emulsifier obtained above were stirred for 30 minutes to obtain the vegetable oil-based polymer. Composition 1C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com