Continuous smelting furnace and ingot casting system with same

A melting furnace and furnace lining technology, which is applied in the field of ingot casting system and continuous melting furnace, can solve the problems that refractory copper alloys cannot be continuously smelted, and achieve the effects of preventing oxidation, uniform alloy composition and fast melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

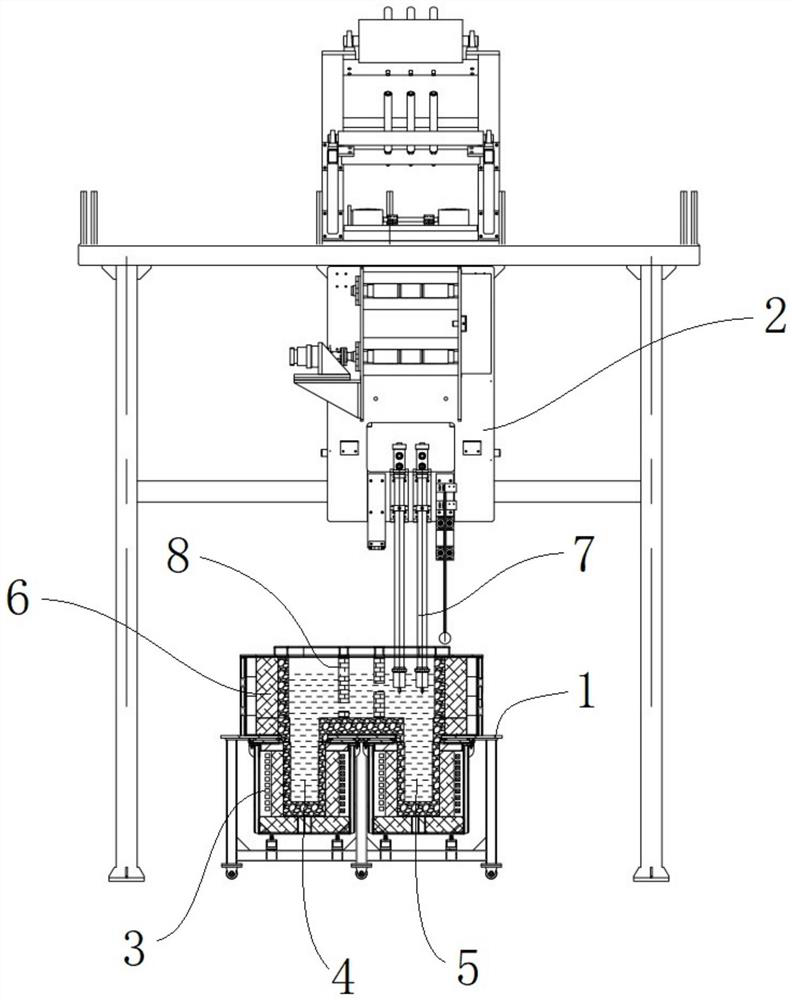

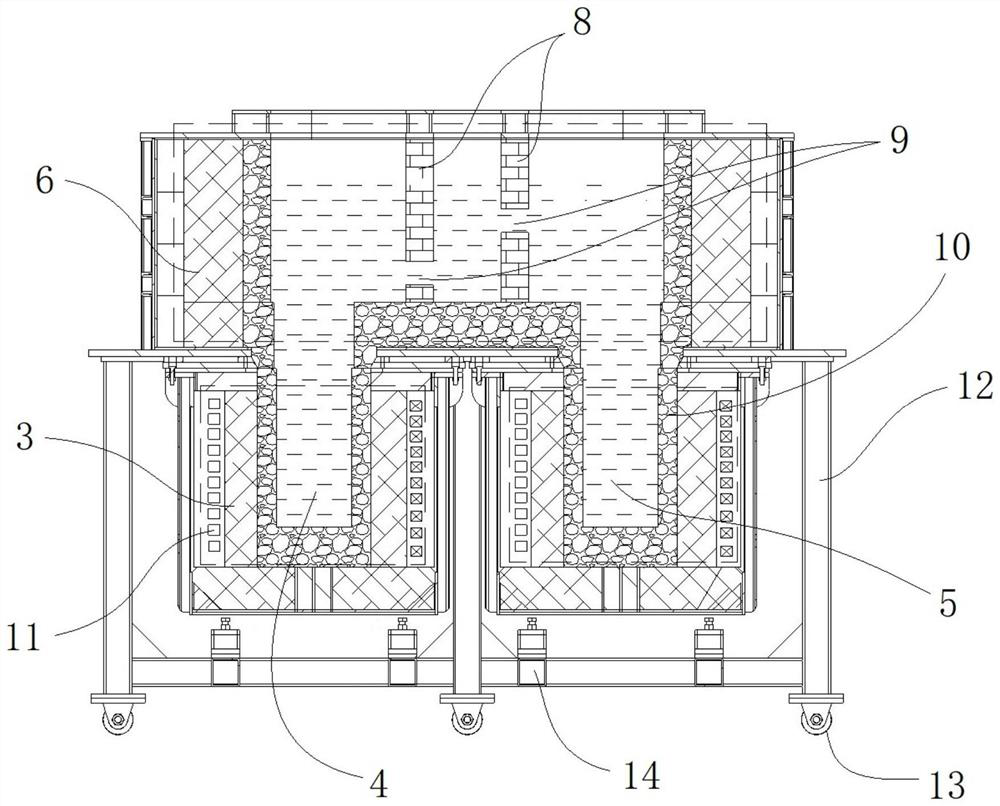

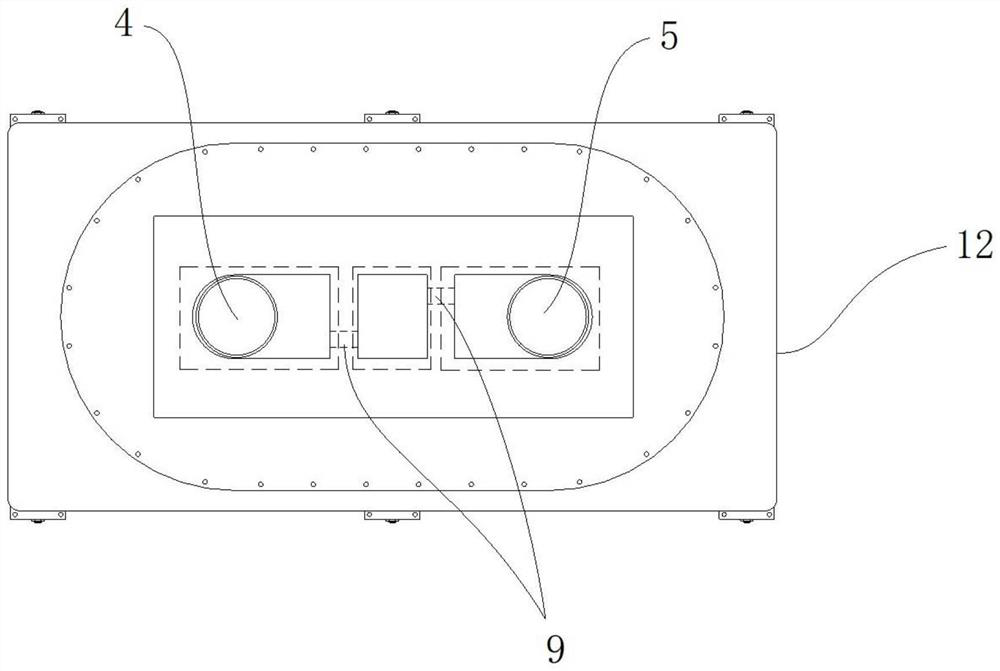

[0036] Such as figure 1As shown, it is a specific implementation of the ingot casting system provided in this embodiment, including: a continuous smelting furnace 1 and a casting machine 2 erected above the continuous smelting furnace 1, and the continuous smelting furnace 1 has a parallel arrangement Two coreless intermediate frequency induction furnaces 3, one of which has a smelting bin 4 for smelting, and the other coreless intermediate frequency induction furnace 3 has a casting bin 5 for heat preservation. The casting machine 2 communicates with the casting bin 5 through an upward channel 7 . The continuous smelting furnace 1 also includes: an underflow holding furnace 6, the underflow holding furnace 6 is connected above the two coreless intermediate frequency induction furnaces 3 arranged side by side, and the bottom of the underflow holding furnace 6 is connected to each The top of the coreless intermediate frequency induction furnace 3 is connected, and the submerge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com