Zinc-particle processing method for making electrogalvanizing steel plate

A processing method, electrogalvanizing technology, applied in the field of metal particle processing, can solve the problems of finished zinc particle pollution, low labor productivity, large maintenance, etc., and achieve the effects of reduced processing cost, low processing energy consumption, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

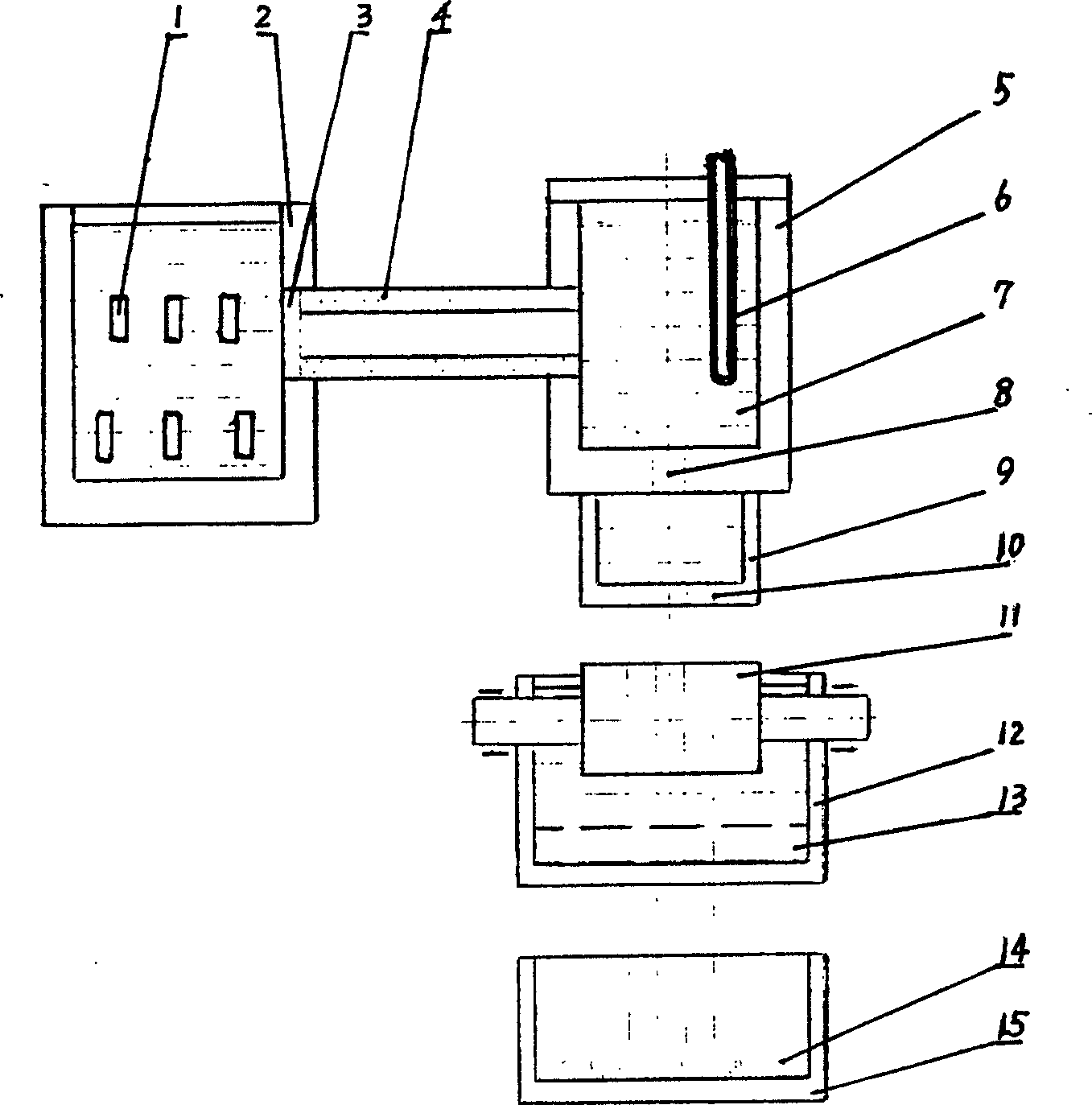

[0040] First put the zinc ingot 1 in the melting furnace 2, the melting furnace is a 50kw resistance furnace, after the molten zinc is melted, because its density is lower than that of the zinc ingot, the molten zinc floats up, and the molten zinc flows out of the melting furnace from the liquid outlet 3, and the liquid is discharged The height from the mouth to the liquid level is 55mm. The zinc liquid flows into the holding furnace 5 through the graphite tube 4 with a diameter of φ18mm. The holding furnace adopts a ceramic inner heating sleeve 6 for heating, and the temperature of the zinc liquid 7 is controlled at 436-440°C. 2 Protection against surface oxidation of zinc liquid. The through hole 8 in the lower part of the holding furnace is connected with the metering device 9, and the zinc liquid flows into the metering device through the through hole, and directly drips onto the graphite cooling roller 11 after passing through the drip nozzle 10, and the dripping distance...

Embodiment 2

[0042] First, place the zinc ingot 1 in the melting furnace 2. The melting furnace is a 46kw resistance furnace. After the molten zinc is melted, because its density is lower than that of the zinc ingot, the molten zinc floats up, and the molten zinc flows out of the melting furnace from the liquid outlet 3. The height to the liquid level is 62mm. The zinc liquid flows into the holding furnace 5 through the ceramic tube 4 with a diameter of φ12mm. The holding furnace adopts a ceramic inner heating sleeve 6 for heating, and the temperature of the zinc liquid 7 is controlled at 437-442°C. The surface of the zinc liquid is oxidized. The through hole 8 in the lower part of the holding furnace is connected with the metering device 9. The zinc liquid flows into the metering device through the through hole, and directly drops onto the graphite cooling roller 11 after passing through the drip nozzle 10. The dripping distance from the drip nozzle outlet to the cooling roller surface is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com