Cerium-based metal organic framework derivative material with synergistic effect with low-temperature plasma as well as preparation method and application of cerium-based metal organic framework derivative material

A low-temperature plasma, synergistic technology, applied in the preparation/processing of rare earth metal compounds, separation methods, chemical instruments and methods, etc., can solve the problems of poor reaction performance and uncontrollable product morphology, and achieve low cost, excellent Catalytic performance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

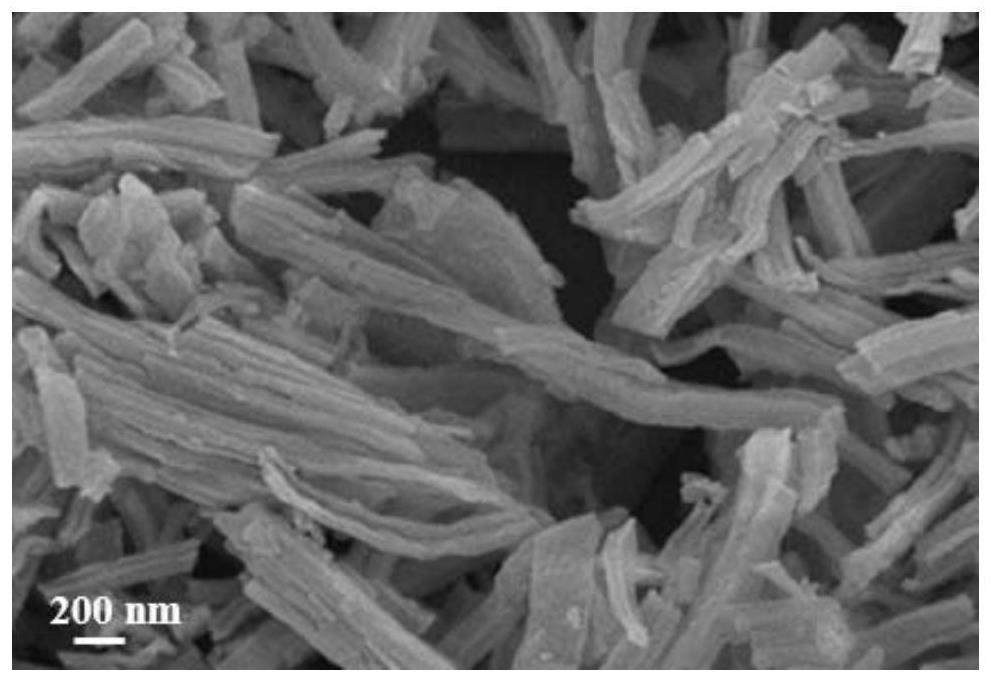

[0029] Weigh 8.6844g Ce(NO 3 ) 3 ·6H 2 O and 4.2000g 1,3,5-H 3 BTC was added to 100 mL of deionized water, and stirred at room temperature at a stirring rate of 500 rpm until completely dissolved. Then the two precursor solutions were mixed, 200 mL of deionized water and 400 mL of absolute ethanol were added in sequence, and the mixture was stirred at room temperature for 30 min, and then left to stand for 1 h. The solution after standing was centrifuged at 4000 rpm to obtain a white solid product, which was then centrifuged and washed three times with deionized water, and vacuum-dried at 60° C. for 12 hours. Ce-BTC (sacrificial template) was obtained by grinding as a white solid powder. Then in the air at a rate of 1 °C / min, the temperature program was raised from room temperature to 250 °C, and the Ce-BTC was heat-treated for 6 h to obtain CeO 2 -250 catalyst.

Embodiment 2

[0031] The specific steps of Example 2 are basically the same as those of Example 1, except that the heat treatment temperature is changed from 250°C to 300°C. Weigh 8.6844g Ce(NO 3 ) 3 ·6H 2 O and 4.2000g1,3,5-H 3BTC was added to 100 mL of deionized water, and stirred at room temperature at a stirring rate of 500 rpm until completely dissolved. Then the two precursor solutions were mixed, 200 mL of deionized water and 400 mL of absolute ethanol were added in sequence, and the mixture was stirred at room temperature for 30 min, and then left to stand for 1 h. The solution after standing was centrifuged at 4000 rpm to obtain a white solid product, which was then centrifuged and washed three times with deionized water, and vacuum-dried at 60° C. for 12 hours. Ce-BTC was obtained as a white solid powder by grinding. Then, the temperature program was raised from room temperature to 300 °C at a rate of 1 °C / min in air, and Ce-BTC was heat-treated for 6 h to obtain CeO 2 -300 ...

Embodiment 3

[0034] The specific steps of Example 3 are basically the same as those of Example 1, except that the heat treatment temperature is changed from 250°C to 400°C. Weigh 8.6844g Ce(NO 3 ) 3 ·6H 2 O and 4.2000g1,3,5-H 3 BTC was added to 100 mL of deionized water, and stirred at room temperature at a stirring rate of 500 rpm until completely dissolved. Then the two precursor solutions were mixed, 200 mL of deionized water and 400 mL of absolute ethanol were added in sequence, and the mixture was stirred at room temperature for 30 min, and then left to stand for 1 h. The solution after standing was centrifuged at 4000 rpm to obtain a white solid product, which was then centrifuged and washed three times with deionized water, and vacuum-dried at 60° C. for 12 hours. Ce-BTC was obtained as a white solid powder by grinding. Then heat the Ce-BTC for 6 h in the air from room temperature to 400 °C at a rate of 1 °C / min to obtain CeO 2 -400 Catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com