Rapid brewing type coarse grain recombined rice and preparation method thereof

A technology for rice and coarse grains, which is applied in the direction of yeast-containing food ingredients, food ingredients as taste improvers, and food forming, etc. It can solve the problems of insufficient nutrition, poor taste of rice, and single formula, and achieve clean ingredients and brewing The effect of short time and high health attribute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

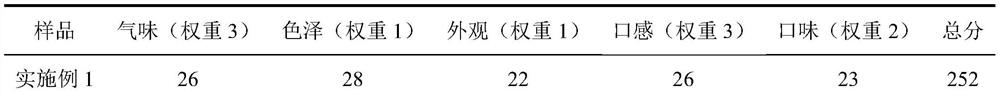

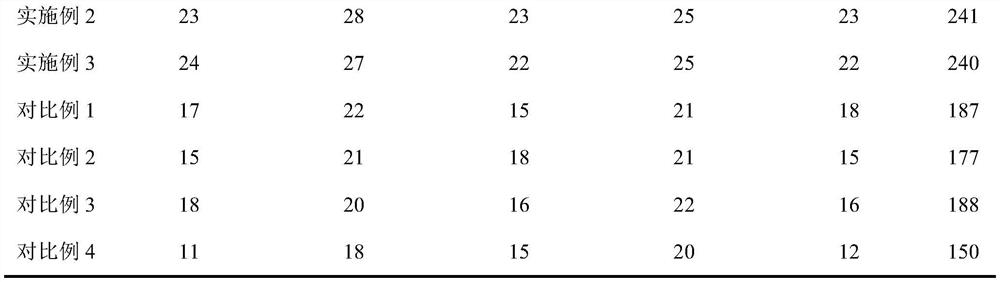

Embodiment 1

[0041] The present invention first provides a fast brewed coarse grain recombinant rice, which is measured by weight, and the recombinant rice comprises 45 rice flour, 15 black rice flour, 3 oatmeal powder, 3 buckl powder, 2 brown rice flour, 2 red bean flour, 2 buckwheat flour, 2 chickpea powder, 2 black bean powder, 2 white kaper powder, 1 yeast powder, 10 high-grain corn starch, 8 soybeans separation protein powder.

[0042] Next, the present invention provides the preparation method of the above-mentioned fast brewed coarse grain recombinant rice, the method comprising the steps of:

[0043] (1) Take the rice, black rice, oatmeal, bucka, brown rice, red beans, buckwheat, hawk beans, black beans, and white kidney beans to grind the powder into the powder, and it is back for 100 mesh sieves.

[0044] (2) Take the above steps of 45, 15 of the black rice noodles, 3 oatmeal powder, 3 buckwheat flour, 2 brown rice flour, 2 red bean powder, 2 buckwheat powder, 2 chickpea powder, There ...

Embodiment 2

[0050] The present invention first provides a fast brewed coarse grain recombinant rice, a weight of 50 parts of rice flour, 20 of the black rice powder, 5 oatmeal flour, 2 buffer flour, 2 coplan rice powder, Red bean powder, 2 buckwheat flour, 2 chickpea powder, 2 black bean powder, 3 white kidney flour, 2 golden powder, 8 high-grain corn starch, 10 soy separation protein powder.

[0051] Next, the present invention provides the preparation method of the above-mentioned fast brewed coarse grain recombinant rice, the method comprising the steps of:

[0052] (1) Take the rice, black rice, oatmeal, bucka, brown rice, red beans, buckwheat, hawk beans, black beans, and white kidney beans to grind the powder into the powder, and it is back for 100 mesh sieves.

[0053] (2) 50 parts of the above steps, 20 of the black rice noodles, 5 oatmeal powder, 2 buffer flour, 2 brown rice flour, 3 red bean powder, 2 buckwheat powder, 2 chickpea powder, There were 2 black bean flour, 3 of the white...

Embodiment 3

[0059] The present invention first provides a fast brewed coarse grain recombinant rice, which is measured by weight, and the recombinant rice includes 40 parts of rice noodles, 10 black rice flour, 4 oatmeal powder, 3 buckwheat flour, 5 coplan rice powder, There are 5 red bean powder, 5 buckwheat powder, 5 eagle soy flour, 4 black bean powder, 4 serum powder, 1.5 percentage powder, 5 high-grain corn starch, 5 soy separation protein powder.

[0060] Next, the present invention provides the preparation method of the above-mentioned fast brewed coarse grain recombinant rice, the method comprising the steps of:

[0061] (1) Take the rice, black rice, oatmeal, bucka, brown rice, red beans, buckwheat, hawk beans, black beans, and white kidney beans to grind the powder into the powder, and it is back for 100 mesh sieves.

[0062] (2) Take the above steps 40 parts, 10 black rice flour, 4 oatmeal powder, 3 buckarot powder, 5 brown rice flour, 5 red bean powder, 5 buckwheat powder, 5 豆 粉 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com