Thermal shape memory gel material and its prepn

A gel material and memory technology, applied in the field of thermal shape memory gel material and its preparation, can solve the problems of small adjustment range, lack of effective means for the complexity of the copolymerization reaction, and the inability to purposefully adjust the shape memory temperature of the material, etc. , to achieve the effect of wide deformation response temperature, simple preparation process and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

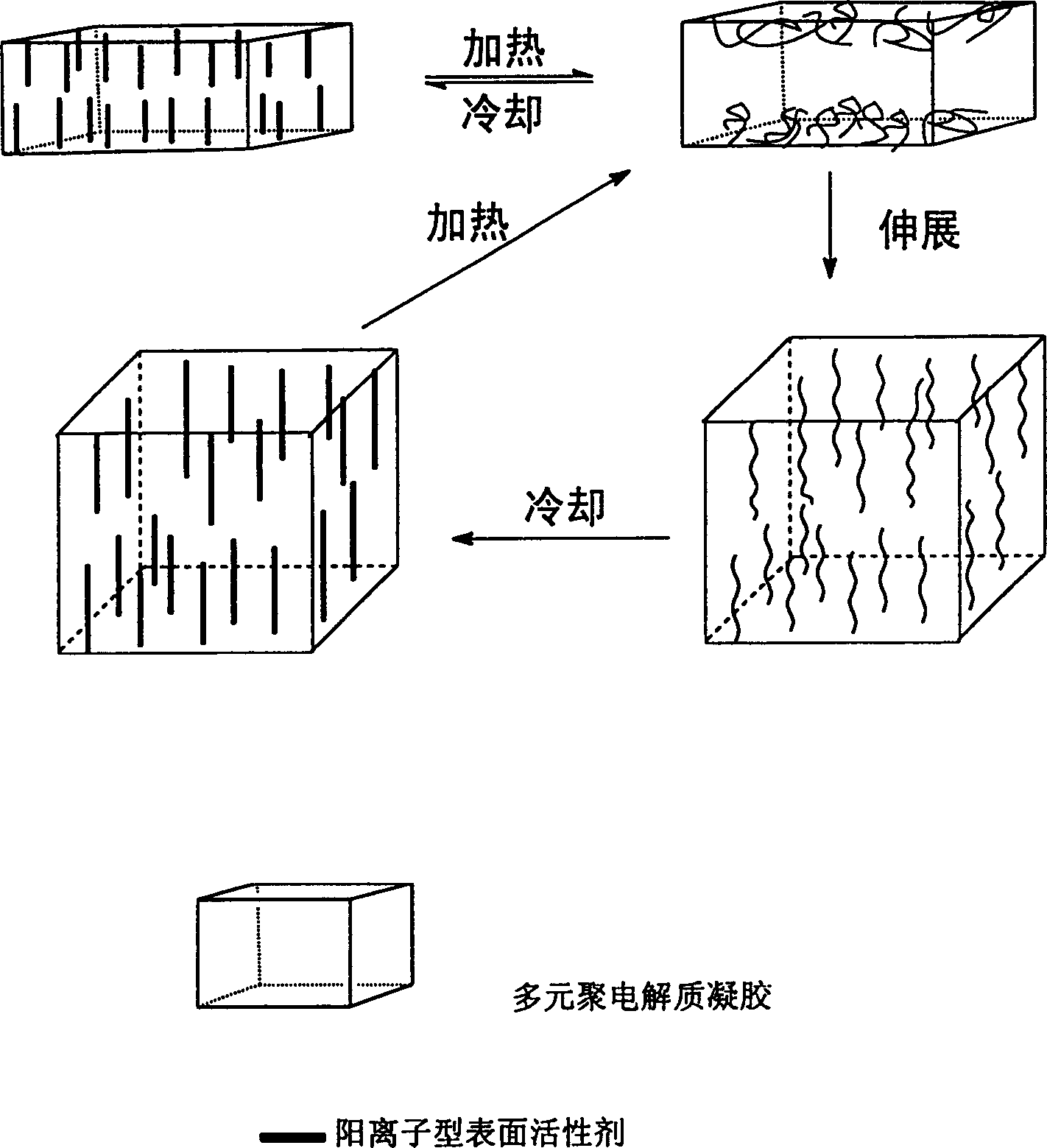

[0019] The polyelectrolyte gel network was synthesized in deionized water, mixed with equal concentrations of acrylic acid and acrylamide aqueous solution, with 1 mol% potassium persulfate as the initiator, 1 mol% methylenebisacrylamide as the crosslinking agent, and polymerized at 60 ° C for 24 Hours, a colorless transparent polyacrylic acid-co-acrylamide gel was obtained.

[0020] After immersing the gel in deionized water to reach swelling equilibrium, take it out, and put it into the cetyltrimethylammonium bromide aqueous solution of the same concentration as the acrylic acid solution for compounding. After the compounding is complete, dry the compound gel at room temperature When the weight percentage of water is less than 30%, the shape memory gel with a memory temperature of 80° C. can be obtained, and the deformation recovery rate can reach 85%.

Embodiment 2

[0022] Synthesize multi-component polyelectrolyte gel network in organic solvent, mix equal concentrations of 2-methyl-2-acrylamido propane sulfonate and methyl methacrylate in dimethyl sulfoxide solution, add 1mol% azo Diisobutyronitrile was used as the initiator, 1mol% methylenebisacrylamide was used as the cross-linking agent, and it was polymerized at 60°C for 24 hours to obtain colorless and transparent polysodium 2-methyl-2-acrylamidopropanesulfonate-co- Methyl methacrylate gel.

[0023] Immerse the gel in deionized water to wash away dimethyl sulfoxide, fully swell to swelling equilibrium, take it out, and put it into cetyl Composite in an aqueous solution of trimethylammonium bromide, after complete compounding, dry the composite gel at room temperature to constant weight (water content is 0%), and obtain a shape-memory gel with a deformation temperature of 104°C and a deformation recovery rate Up to 80%.

Embodiment 3

[0025] The polyelectrolyte gel network was synthesized in deionized water, 1 mol% potassium persulfate and 1 mol% methylenebisacrylamide were added to 1mol / L acrylic acid aqueous solution, and polymerized at 60°C for 24 hours to obtain a colorless transparent polyacrylic acid gel.

[0026] Immerse the gel in deionized water to reach swelling equilibrium, take it out, and put it into the cetyltrimethylammonium bromide aqueous solution of the same concentration as the acrylic acid solution for compounding. After the compounding is complete, dry the compound gel at room temperature When the weight percentage of water is less than 30%, the shape memory gel with a deformation temperature of 97° C. can be obtained, and the deformation recovery rate can reach 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com