Fatigue life prediction method based on fatigue crack propagation

A fatigue life prediction and fatigue crack propagation technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. problems such as accurate appearance prediction, to simplify the analysis process, reduce computing costs, and improve computing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

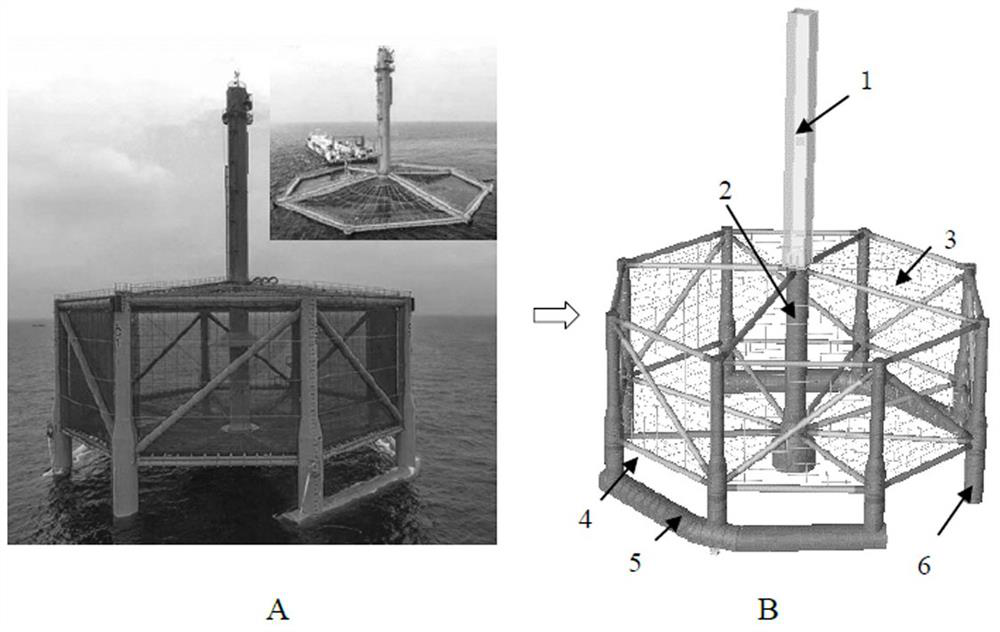

[0099] In order to verify a fatigue life prediction method based on fatigue crack growth proposed by the present invention, the present invention takes the fatigue life prediction of a fully submersible fish farming platform as an example to further elaborate.

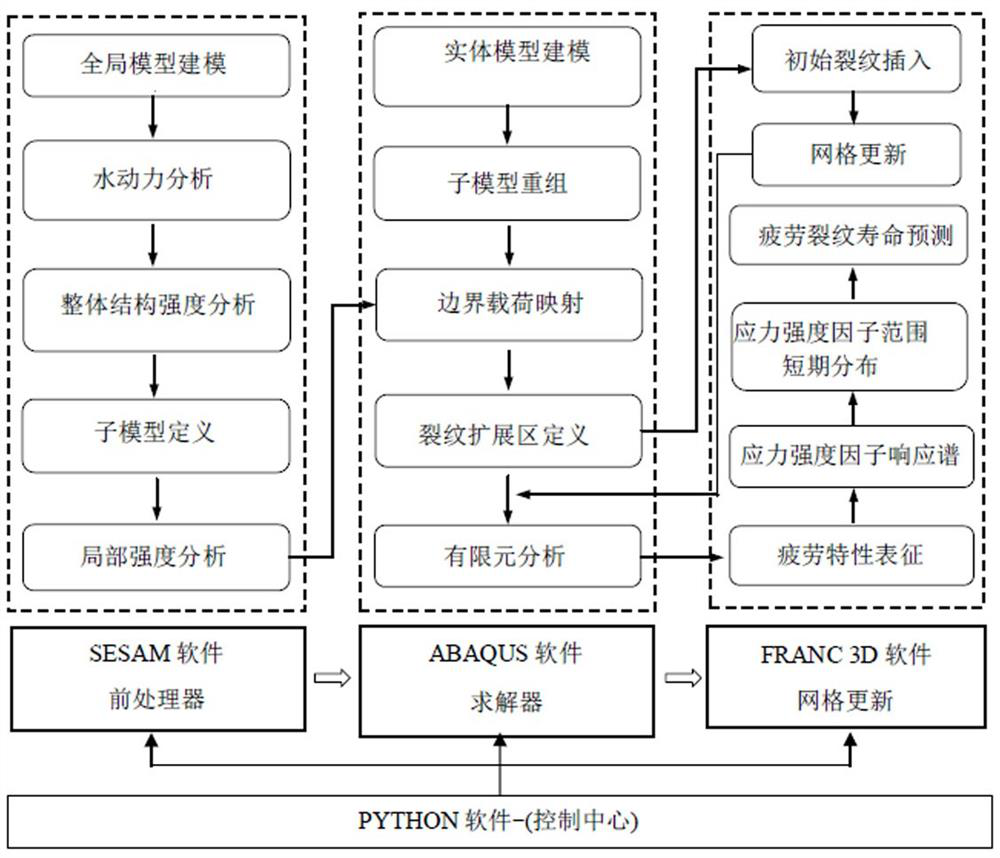

[0100] Such as Figure 1~14 As shown, this embodiment specifically includes the following steps:

[0101] S1: Global model modeling

[0102] The model of this embodiment includes S11 geometric model, S12 hydrodynamic model and S13 structural model, wherein,

[0103] S11: The creation of the geometric model should include the size and structure information of the structure. According to the structural characteristics, different modeling methods are selected; in this embodiment, the larger-sized middle column 2, strut 4, peripheral column 6 and buoy box 5 adopt plate / surface modeling, while the fishnet 3 is modeled by beams due to its large slenderness ratio, and the superstructure 1 is directly simplified as a piece ...

Embodiment 2

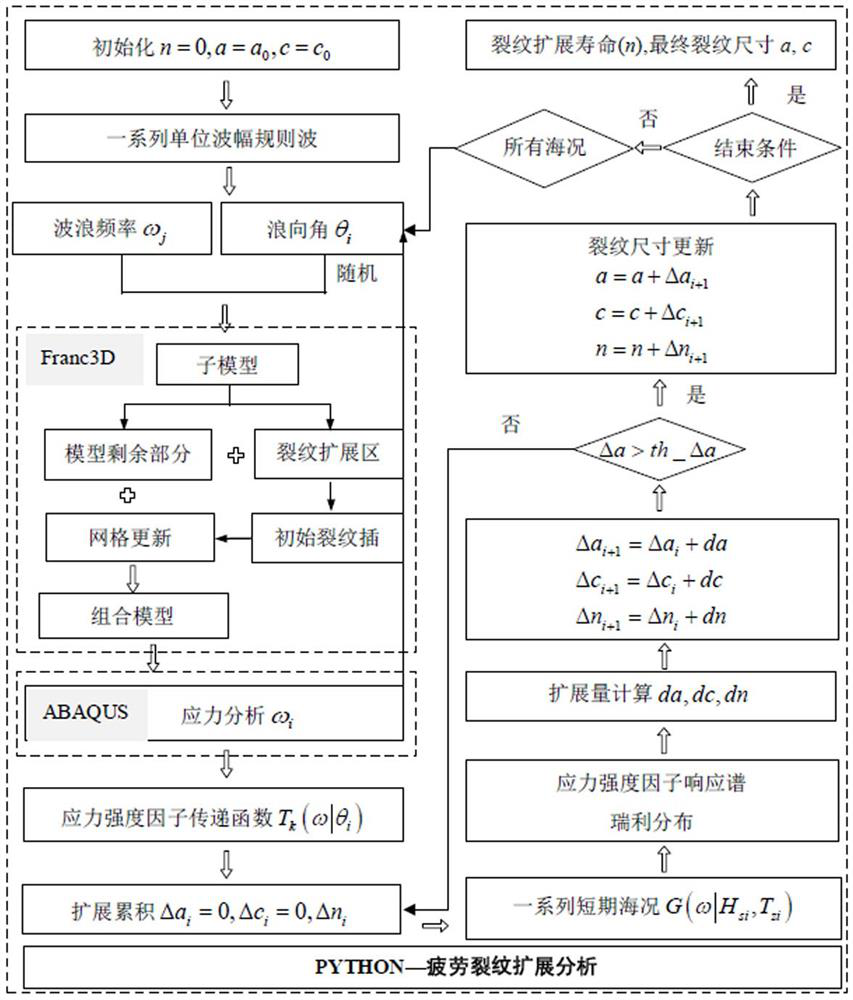

[0176] Preferably, this embodiment includes adaptive crack increment optimization control. The calculation of the stress intensity factor of the crack front in the process of fatigue crack growth requires multiple insertions of cracks and updating of the finite element model, so the expansion increment threshold is set using an adaptive step size , during the simulation process, it is regarded as a parameter related to the crack size, and only when the crack growth increment exceeds a threshold value, the crack insertion and the update of the finite element model will be performed. If the crack size under each sea condition is updated, the simulation accuracy can be effectively improved, but frequent crack insertion and model update will inevitably lead to multiple solutions of the SIF transfer function and repeated calculations of the finite element model, which will undoubtedly lead to The feasibility of the fracture mechanics method in the fatigue life prediction of actual e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com