Cold state simulation device for coking process of heating surface of incinerator

A cold-state simulation and surface coking technology, which is applied in the field of ash deposition and coking simulation experiments in incinerators, can solve the problems of inability to simulate chemical reaction deposition and coking process, limited industrial production guidance, and difficulty in simulating fly ash phase change deposition process, etc. Achieve the effect of real generation process, convenient control and convenient experiment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

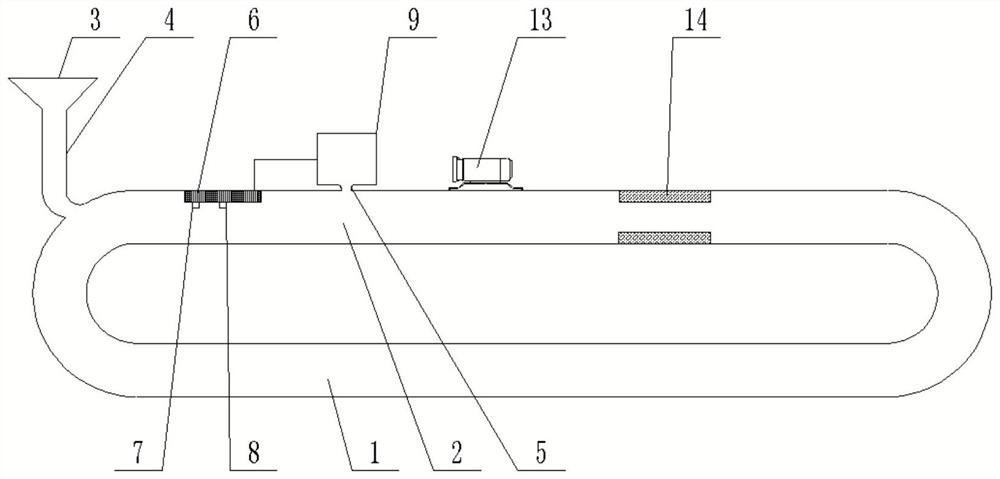

[0038] refer to Figure 1-2 , the circulation passage in this embodiment is an annular pipe structure with two main pipes 1, the main pipes 1 are transparent cylindrical pipes, and any main pipe 1 is located on the top of the other main pipe 1, in fact the circulation passage 1 can use A transparent cylindrical annular container, which is a closed annular pipeline, has good sealing performance and is convenient for observing the progress of the reaction.

[0039] Further optimization scheme, the injection channel includes the injection port 3, the injection port 3 is fixed and communicated with the main pipeline 1 through the first injection pipe 4, the injection port 3 is a funnel-shaped structure, and the injection port 3 and the first injection pipe 4 are overall higher than the circulation channel, inject water into the circulation channel through the injection port 3.

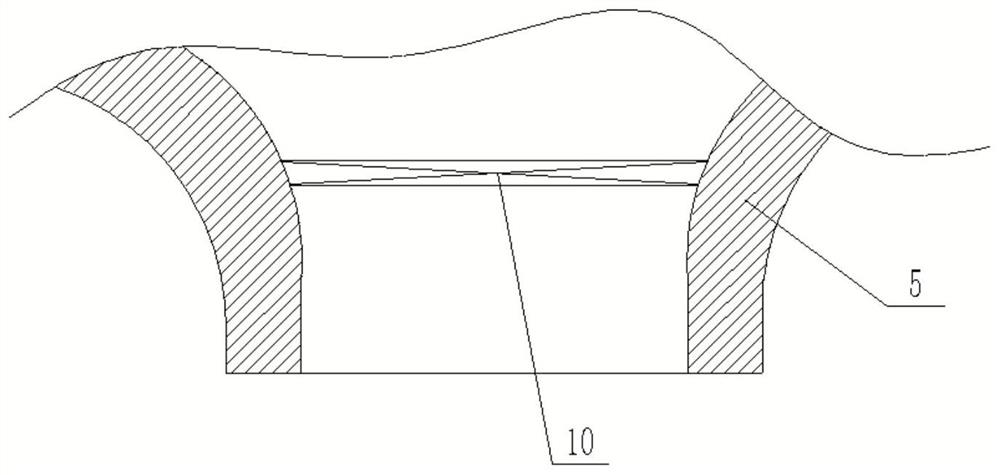

[0040]To further optimize the scheme, the solute addition chamber 2 is fixedly connected through the s...

Embodiment 2

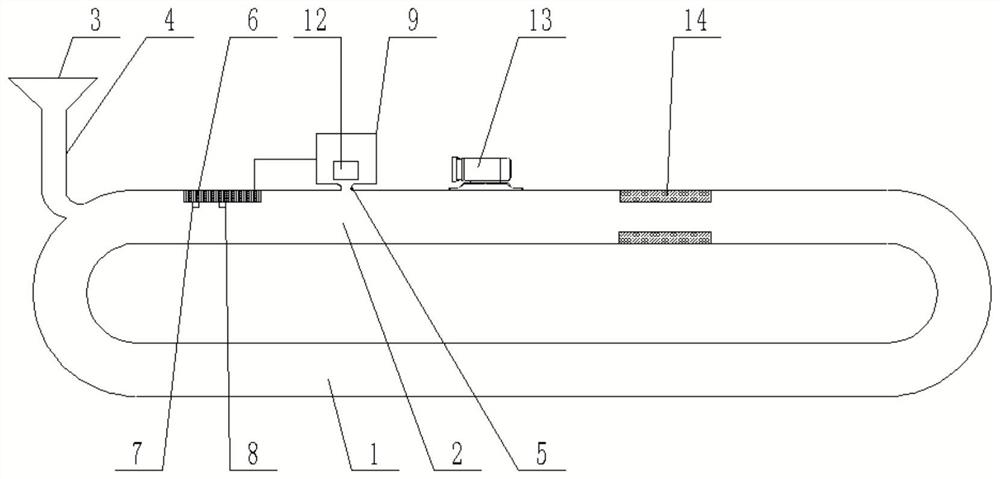

[0045] refer to Figure 3-4 , and the above-mentioned embodiment 1 is only different in that the outlet end of the second injection pipe 5 is detachably connected with a nozzle 11 , and the solute container 9 is provided with a liquid supply pump 12 communicating with the second injection pipe 5 . If there is insufficient liquid concentration, the PID controller 6 controls the solenoid valve 10 to open, and the solute in the solute container 9 is sent out under the action of the liquid supply pump 12, and after passing through the nozzle 11 at the second injection pipeline 5, the solute is sprayed with The form flows into the solute addition chamber 2.

[0046] In this embodiment, the solute is added into the solute adding chamber 2 in the form of injection, and mixed with the liquid to increase the liquid concentration until reaching the required concentration for the reaction.

Embodiment 3

[0048] The difference with the above-mentioned embodiment 1 and embodiment 2 is that the cross-section of the rod part of the reaction structure 14 can be selected as a non-circular shape, such as multi-petal shape, quincunx shape or gear shape, etc., so that the rod body of the reaction structure 14 can be connected with the The contact area of the liquid is larger and the chemical reaction effect is better.

[0049] The rod body of the reaction structure 14 is the electrode of the pewter casting or the active metal element, and the suspension body part of the reaction structure 14 is a pure copper forging, and the pure copper forging extends into the pewter casting; the pure copper forging extends into the pewter casting. The surface of the connecting part has a uniform tin layer, and the connecting part of the pure copper forging protruding into the pewter casting adopts hanging tin, which is filled with soft metal to promote the combination of the connecting part and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com