Preparation method of self-phase-change proppant based on emulsified toughened bio-based epoxy resin

A technology based on epoxy resin and proppant is applied in the field of preparation of self-phase change proppant, which can solve the problems of complex staged laying process and poor migration ability of solid proppant, achieve good migration ability, improve development Efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Synthesis and evaluation of a low-viscosity, low-density bio-based epoxy resin.

[0042] (1) Synthesis of low-viscosity, low-density bio-based epoxy resin.

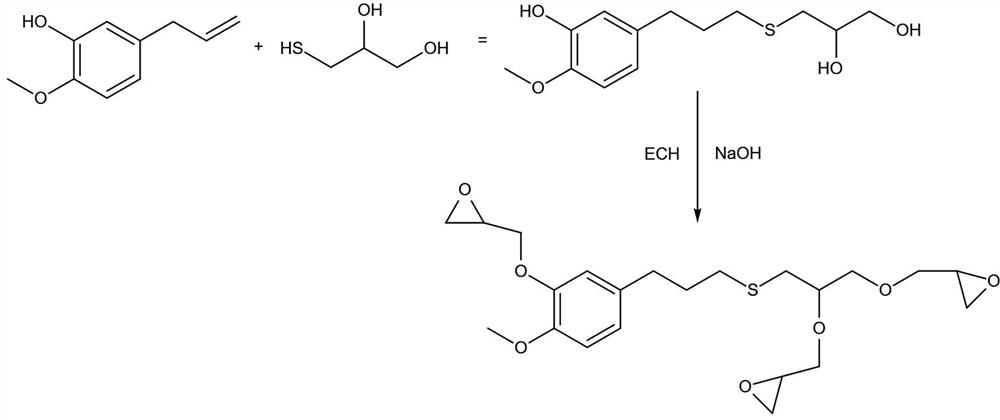

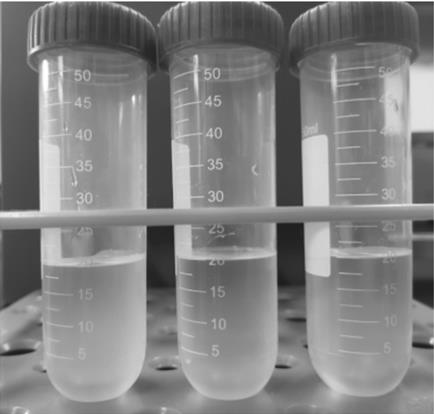

[0043] Using dimethyl sulfoxide as a solvent, eugenol and 1-thioglycerol with a molar ratio of 1:1 and 2% catalyst 4-dimethylaminopyridine (DMAP) of the total mass of the reaction monomer were placed in the solvent and heated at 65 The reaction was carried out at a temperature of ℃ for 4h, and a light yellow product was obtained. Subsequently, at a reaction temperature of 85°C, the above light yellow reaction product was reacted with epichlorohydrin in an ethanol solution with a NaOH mass concentration of 10% for 6 hours, and then the product was purified using a saturated sodium bicarbonate solution to obtain the target bio-based ring. Oxygen resin, the reaction formula and the morphology of the product are as follows figure 1 , figure 2 shown.

[0044] (2) Evaluation of low-viscosity, low-density ...

Embodiment 2

[0058] Example 2: Toughening modification of bio-based epoxy resin.

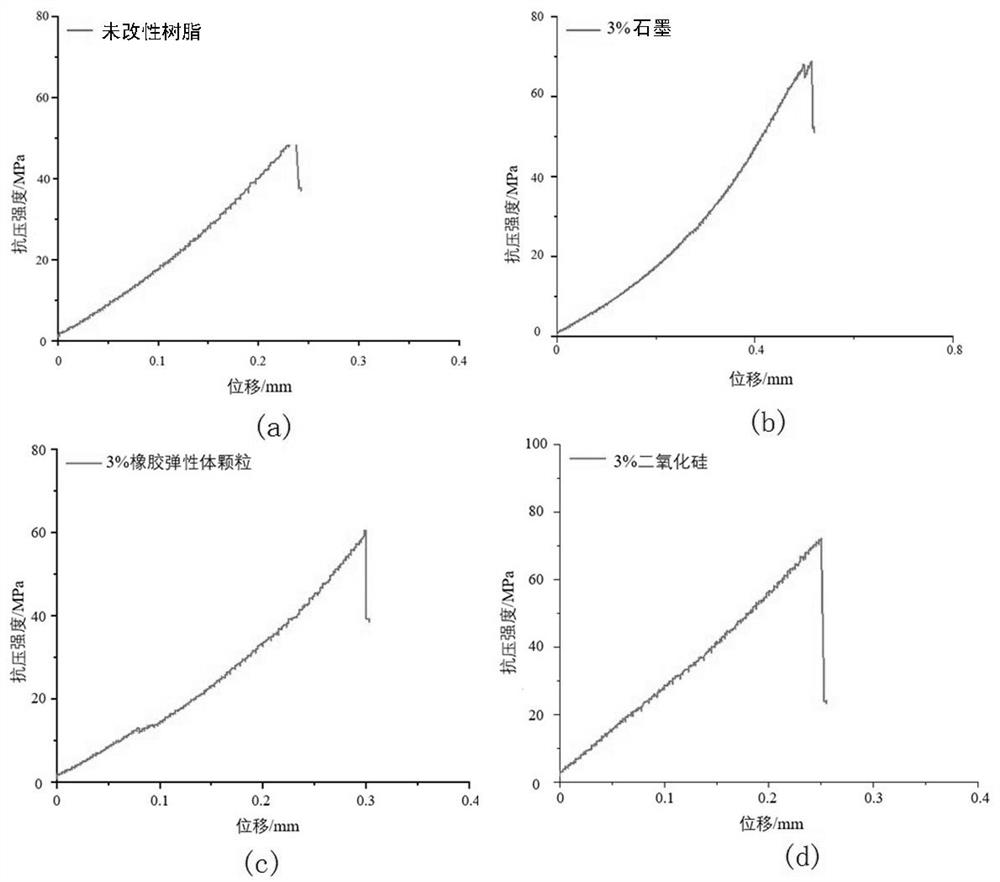

[0059] In order to overcome the shortcomings of epoxy resin such as poor toughness and notch sensitivity, so that the proppant prepared based on the obtained bio-based epoxy resin has better compressive strength, organic components or inorganic components are added to the matrix before curing. The physical method of rigid particles is used to toughen and modify the obtained resin, and the optimal type and amount of added particles are optimized by evaluating the physical properties of the cured resin. The epoxy resin curing agent used in the evaluation experiment is an adduct of diethylenetriamine and butyl glycidyl ether with good curing ability in wet environment. The curing agent has good curing ability in wet environment. When it is 25% of the resin mass, it can be fully cured within 40 minutes at an ambient temperature of 60°C, meeting the needs of supporting reservoirs after on-site fracturing.

[006...

Embodiment 3

[0066] Example 3: Preparation of self-staged emulsified phase change proppant.

[0067] In this example, SiO with a particle size of 50 nm was selected as the self-staged emulsified phase change proppant 2 Particles were used as emulsifier to prepare phase change proppant by Pickering emulsification technique. When the emulsifier is used at a concentration of 0.5%, six kinds of resin proppants with different particle sizes are mainly formed. The particle size of the proppant is as follows: Figure 7 As shown, they are 2.9mm (7 mesh), 1.7mm (12 mesh), 0.95mm (20 mesh), 0.6mm (30 mesh), 0.4mm (40 mesh) and 0.18mm (80 mesh), which can meet the simultaneous Requirements for the mesh number of proppant supporting the near-wellbore zone, main fractures and branch fractures.

[0068] In order to make the obtained proppant suitable for different reservoir environments, in this example, by changing the concentration of the emulsifier, the particle size distribution of the proppant ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com