Warm mixing modified rubber asphalt and preparation method thereof

A technology for modifying rubber and asphalt, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of complex preparation process, low road performance, low preparation efficiency, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

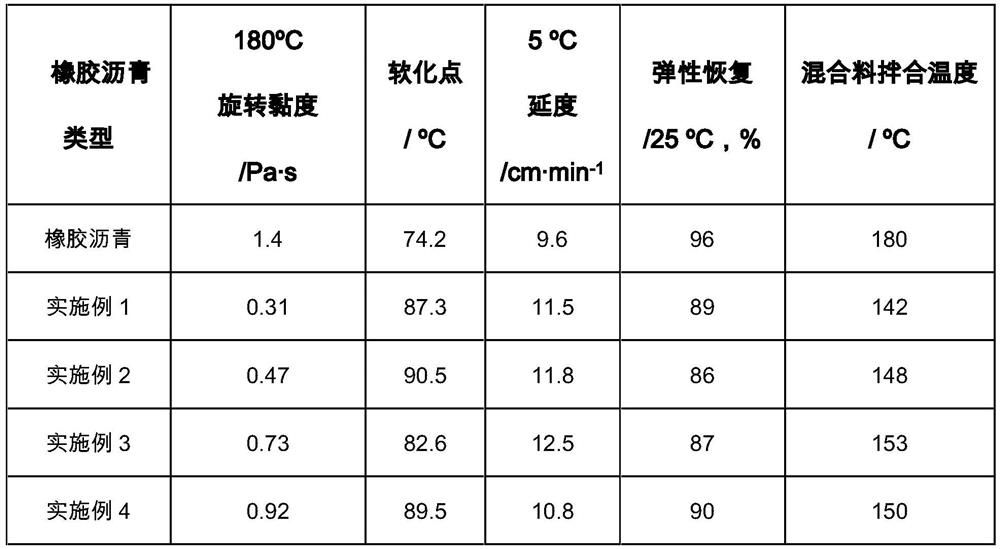

Examples

preparation example Construction

[0032] The above-mentioned method for preparing warm-mixed modified rubber asphalt comprises the following steps:

[0033] 1) In parts by mass, 50-100 parts of waste rubber powder and 5-15 parts of modifier are modified in an internal mixer to prepare modified waste rubber powder;

[0034] (2) In parts by mass, take 15 to 30 parts of the modified waste rubber powder prepared in step (1), 2 to 8 parts of warm mixing agent, 0.4 to 2 parts of catalytic aid and 2 to 2 parts of viscosity reducer Add 10 parts to 80-100 parts of asphalt in turn, heat to 140-150°C, and react with shearing and stirring for 40-60 minutes at a stirring rate of 600-900 rpm;

[0035] (3) After the reaction time is over, add 0.2 to 3 parts of stabilizer to step (2), keep warm for 60 to 90 minutes at a stirring rate of 400 to 600 rpm, and keep warm at a temperature of 140 to 150°C to obtain a warm-mixed modified Rubberized asphalt.

Embodiment 1

[0037] A warm-mix modified rubber asphalt and a preparation method thereof. The preparation method comprises the following steps:

[0038] (1) In parts by mass, 60 parts of waste rubber powder and 5 parts of maleic anhydride were modified in an internal mixer to prepare maleic anhydride modified waste rubber powder.

[0039] (2) In terms of parts by mass, take 15 parts of the maleic anhydride modified waste rubber powder prepared in step (1), 2 parts of surface active warm mixing agent, 0.6 part of methyl succinic acid and 4 parts of fatty amide Add 100 parts of asphalt at 150°C successively, and react with shearing and stirring for 40 minutes at a stirring rate of 600 rpm.

[0040] (3) After the reaction time is over, add 0.2 parts of sulfur to step (2), keep warm for 60 minutes at a stirring rate of 400 rpm, and keep warm at 150°C to prepare warm-mix modified rubber asphalt.

Embodiment 2

[0042] A warm-mix modified rubber asphalt and a preparation method thereof. The preparation method comprises the following steps:

[0043] (1) In parts by mass, 70 parts of waste rubber powder and 8 parts of phthalic acid were modified in an internal mixer to prepare phthalic acid modified waste rubber powder.

[0044] (2) In terms of parts by mass, take 20 parts of the phthalic acid modified waste rubber powder prepared in step (1), 5 parts of organic viscosity-reducing warm mixing agent, 1 part of isopropylacrylamide and oxidation 7 parts of polyethylene wax were sequentially added to 100 parts of asphalt at 140°C, and reacted with shearing and stirring for 40 minutes at a stirring rate of 600 rpm.

[0045] (3) After the reaction time is over, add 1 part of sulfur to step (2), keep stirring at 400 rpm for 60 minutes, and keep warm at 140°C to prepare warm-mixed modified rubber asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com