Friction stir double-rivet welding method for dissimilar alloy

A friction stir and alloy technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as complex matching, structural weight reduction, rivet type, and high shape requirements, achieving short welding time, improved bearing strength, Effect of Low Soldering Heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

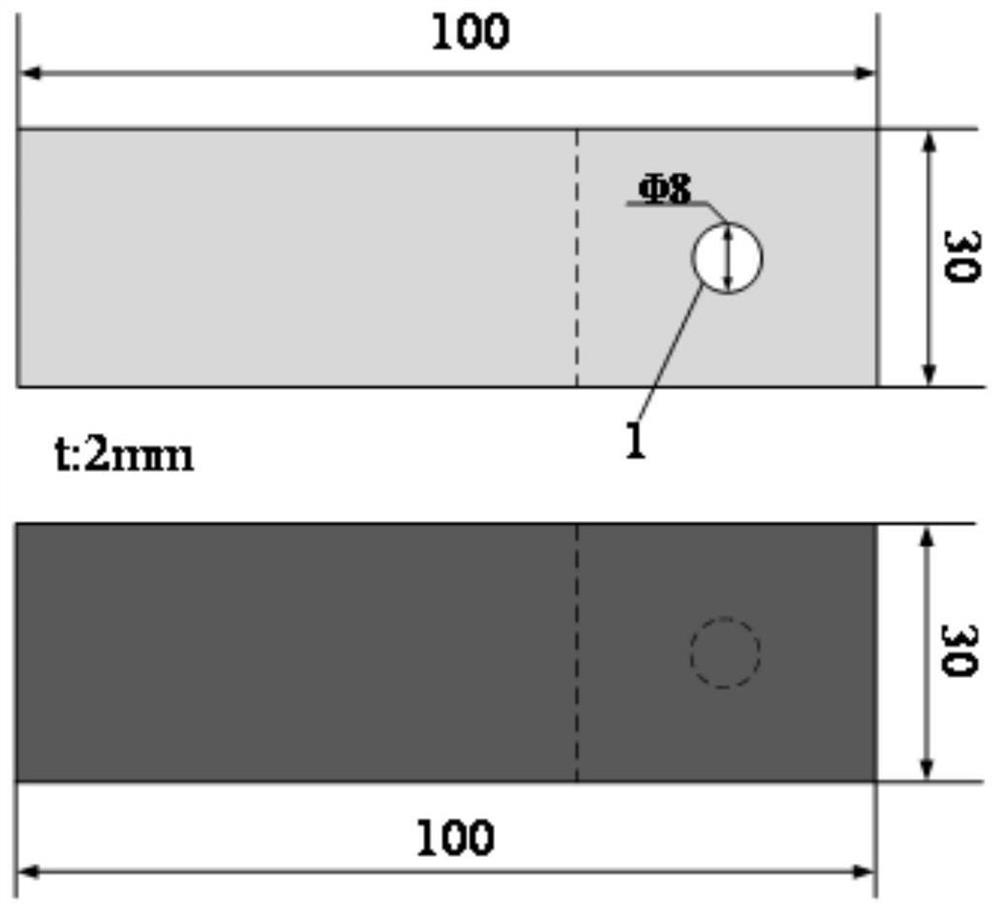

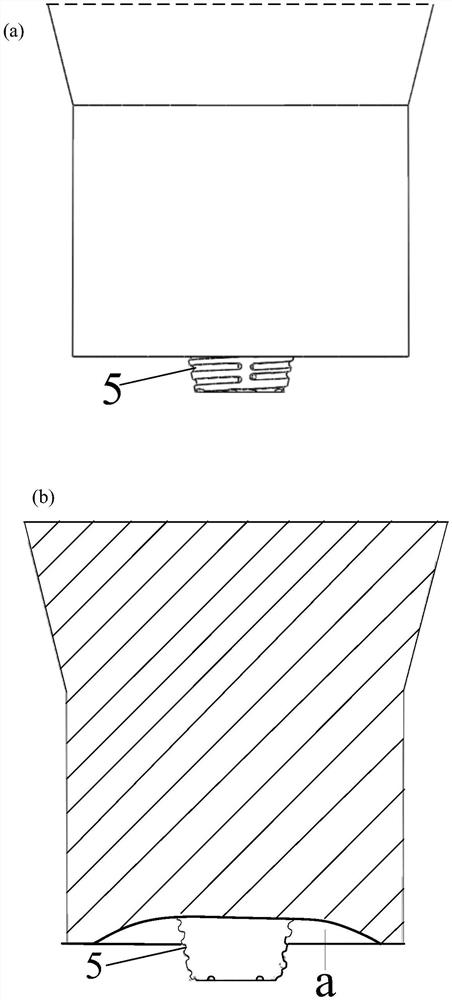

[0074] A friction stir double-rivet welding method for dissimilar alloys is carried out using friction stir double-rivet welding equipment for dissimilar alloys. The schematic diagram of the structure is as follows figure 2 As shown, including the stirring head 3, the stirring head 3 has a large concave shoulder a, the concave angle of the large concave shoulder a is 14°, and the side wall of the stirring needle of the stirring head 3 is provided with a small lift angle through groove 5, The head of the stirring needle is provided with a spiral groove, which is set in this embodiment as a concave spiral groove with a depth of 0.4 mm. The schematic diagram of the three-dimensional structure of the stirring head is as follows image 3 3(a) is a front view, 3(b) is a cross-sectional view, and 3(c) is a bottom view; a schematic diagram of the local structure of the stirring head; a schematic diagram of the local structure of the stirring head is shown in Figure 4 Shown; welding ...

Embodiment 2

[0080] Same as Example 1, the difference is that the length of the stirring needle at the lower part of the shoulder is 2.0 mm, the lower tie position is located at the interface, and the vertical distance between the lower tie position and the interface is 0 mm; the obtained welded joint is as follows Figure 6 As shown, the joint tensile load is 5.45kN.

Embodiment 3

[0082] Same as Example 1, the difference is that the length of the stirring needle at the lower part of the shoulder is 2.2 mm, the lower tie position is located at the lower part of the interface, and the vertical distance between the lower tie position and the interface is 0.2 mm; the frictional heat of the upper plate on the stirring head and the upsetting Under the double action, plastic flow is generated and is extruded to form an aluminum anchor between the rivet and the lower plate material. At the same time, the lower plate material is driven by the stirring head to flow upwards and embedded into the upper plate material to form a copper anchor, which together form an aluminum anchor near the lap interface. Structure 9; the welded joint obtained as Figure 7 As shown, the joint tensile load is 6.35kN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com