Dissimilar metal joint and electric resistance welding method thereof

A dissimilar metal, resistance welding technology, applied in the direction of resistance welding equipment, resistance electrode holder, metal processing equipment, etc., can solve the problems of easy initiation of cracks, low welding strength, large brittle intermetallic compounds, etc., and achieve high-quality connection, method Convenience and the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

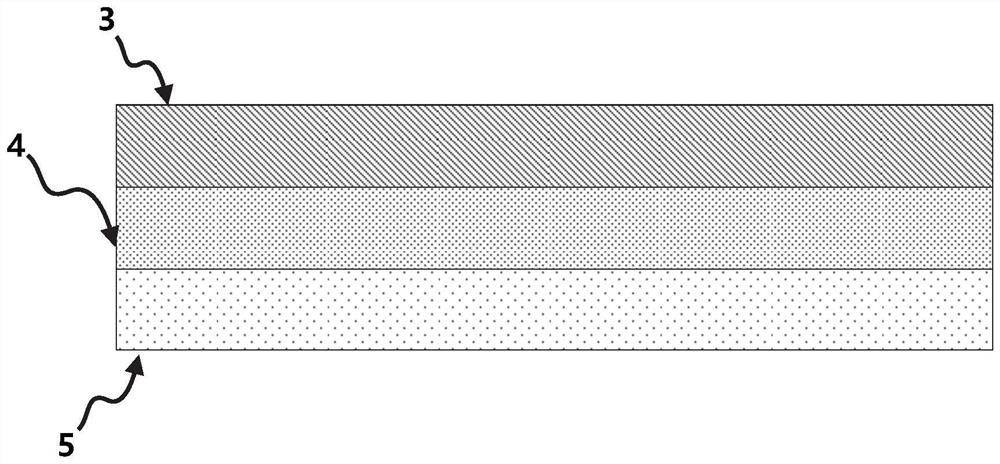

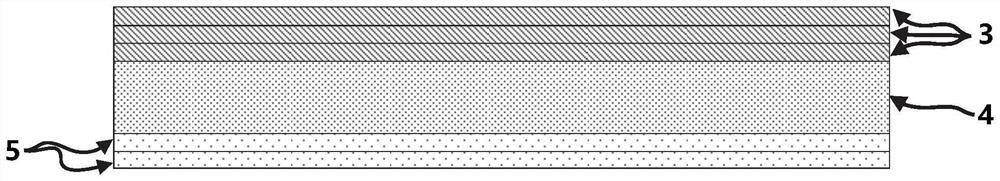

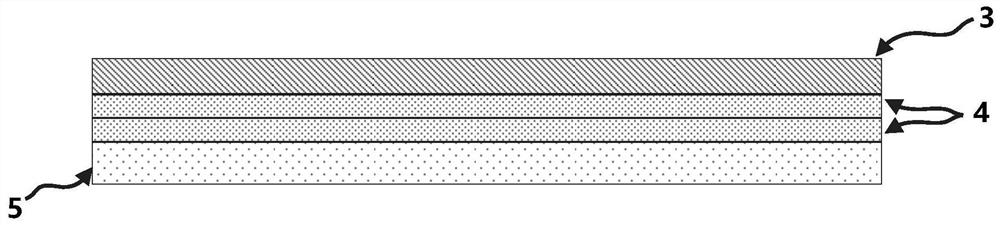

Embodiment 1

[0095] Select CR210 cold-rolled steel with a thickness of 0.8mm and a tensile strength lower than 400MPa as the upper plate 3, AA 6016 aluminum alloy with a thickness of 0.8mm as the inner plate 4, and CR420 cold-rolled steel with a thickness of 1.0mm and a tensile strength lower than 600MPa. Rolled steel is used as the lower plate 5, the first welding electrode 1 and the second welding electrode 2 are ordinary spherical electrodes, and the welding end surface of the electrodes is 6mm; the specific welding process parameters are shown in Table 1, and the peeling fracture after welding is as follows Figure 9 As shown, on the interface between the inner plate 4 and the lower plate 5, there are solidified light metal splashes 7 distributed radially around the solder joints; the tensile shear load test results of the welded joints are shown in Table 2, because A solid steel-to-steel welding nugget is formed between the first type of metal plates 3, 5 and the second metal plate 4, ...

Embodiment 2

[0097] The CR210 cold-rolled steel with a thickness of 1.0 mm and a tensile strength lower than 400 MPa is selected as the upper plate 3, and the AA 5754 aluminum alloy with a thickness of 1.2 mm is used as the inner plate 4. The difference in material selection from Example 1 is that the inner plate 4 is 5 Aluminum alloy; CR420 cold-rolled steel with a thickness of 1.0mm and a tensile strength lower than 600MPa is used as the lower plate 5, and the first welding electrode 1 and the second welding electrode 2 are ordinary spherical electrodes, and the welding end surface of the electrode is 6mm. The welding process parameters are shown in Table 1, and the cross-sectional metallographic diagram of the joint is shown in Figure 10 shown. After welding, the tensile shear load test is carried out on the joint, and the tensile shear load-displacement curve is as follows Figure 11 shown. The tensile shear load test shows that the joint has a very high tensile shear strength of 72...

Embodiment 3

[0099] Select Q&P980 cold-rolled high-strength steel with a thickness of 1.0mm as the upper plate 3, and its tensile strength is generally not less than 1000MPa; AA 5754 aluminum alloy with a thickness of 1.5mm is used as the inner plate 4, and Q&P1180 cold-rolled high-strength steel As the lower plate 5, its tensile strength is generally not less than 1200MPa; the first welding electrode 1 and the second welding electrode 2 are both ordinary spherical electrodes, and the welding end surface of the electrodes is 6mm. The specific welding process parameters are shown in Table 1. After welding, the tensile shear load test was carried out on the joint. The test showed that the joint also had a very high tensile shear strength, reaching 7557.6N. The peak load test results of tensile shear are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com