Power rail circuit for high-voltage Buck converter

A converter and power rail technology, which is used in high-efficiency power electronic conversion, conversion of DC power input to DC power output, instruments, etc. Suitable for low power requirements and other issues, to achieve the effect of small changes, reduced power consumption, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

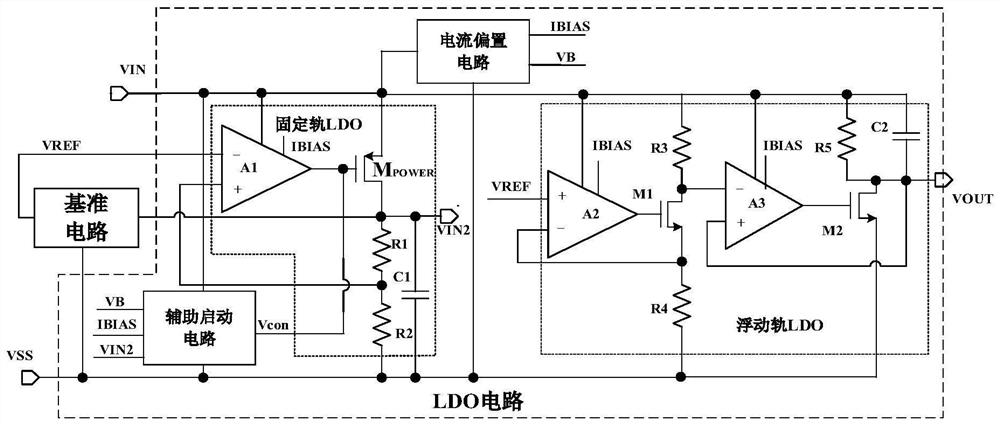

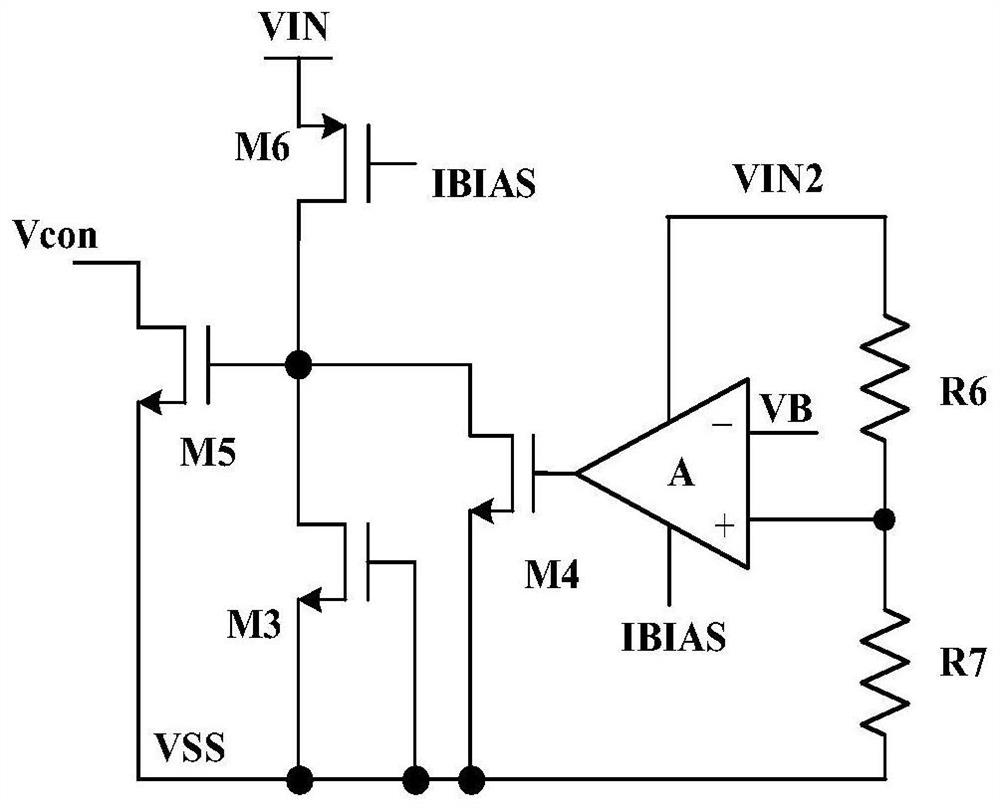

[0016] figure 1 It is a schematic diagram of the overall structure of the power rail circuit of the high-voltage Buck converter proposed by the present invention. Including LDO circuit and reference circuit. Among them, the LDO circuit includes a current bias circuit, an auxiliary start-up circuit, a fixed-rail LDO circuit, and a floating-rail LDO circuit. figure 2 The circuit diagram for auxiliary start.

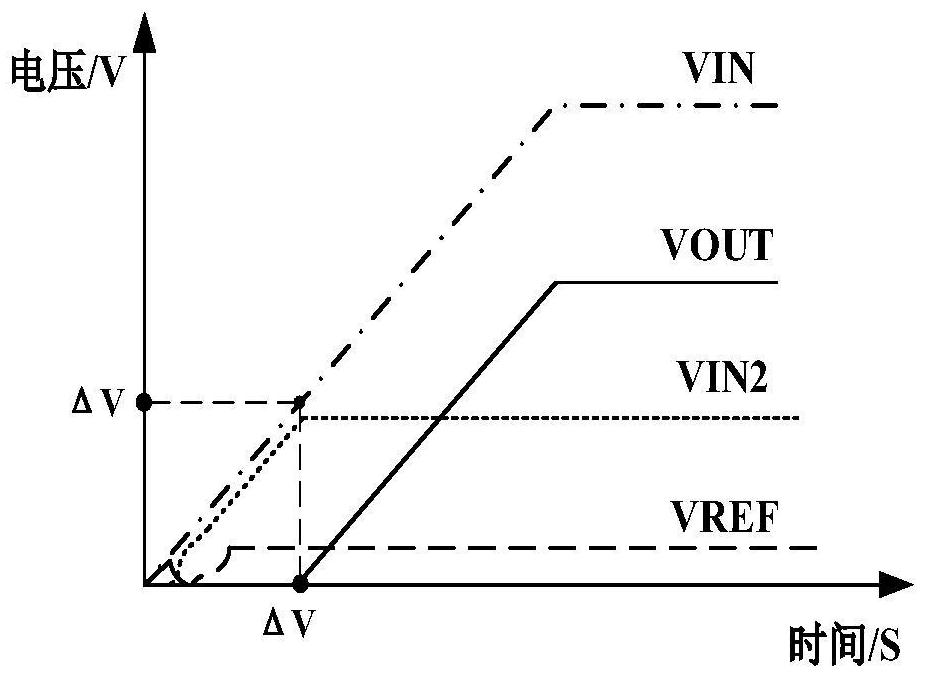

[0017] The current bias circuit generates the bias current IBIAS required by each module inside the LDO and the reference voltage VB of the auxiliary start-up circuit; the auxiliary start-up circuit compares the output signal of the fixed-rail LDO in the initial power-on stage when the reference circuit is not established. The divided voltage signal of VIN2 and the reference voltage VB, the control signal Vcon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com