Method for controlling thickness of oxide layer on surface of gallium antimonide single crystal

A technology for oxide layer thickness and control methods, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc. Problems such as the increase in the thickness of the surface oxide layer, to achieve the effect of controlling the thickness of the oxide layer, meeting the requirements of use, and reducing the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

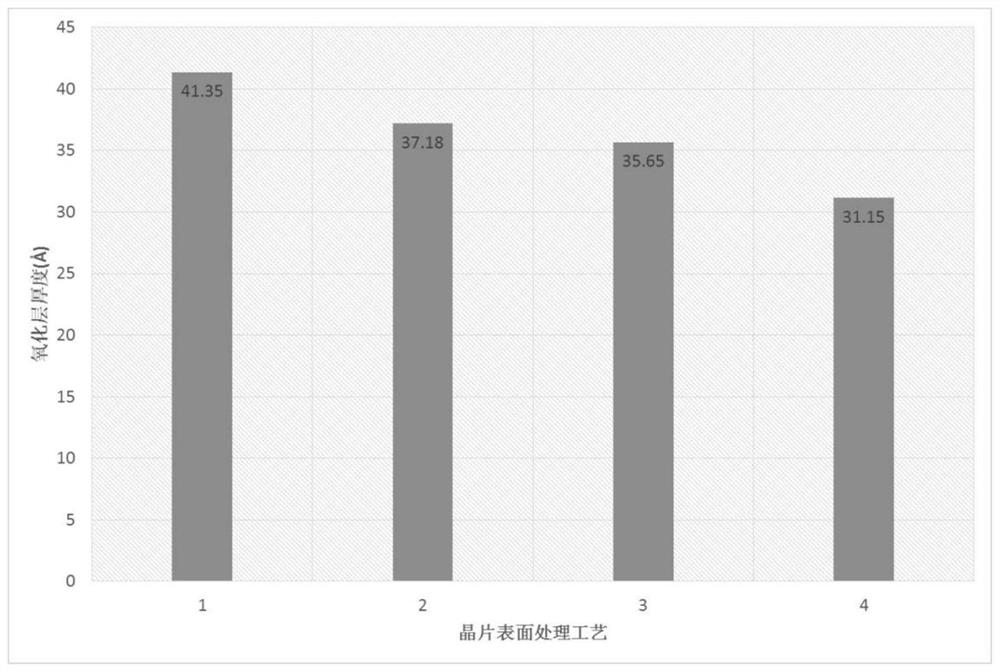

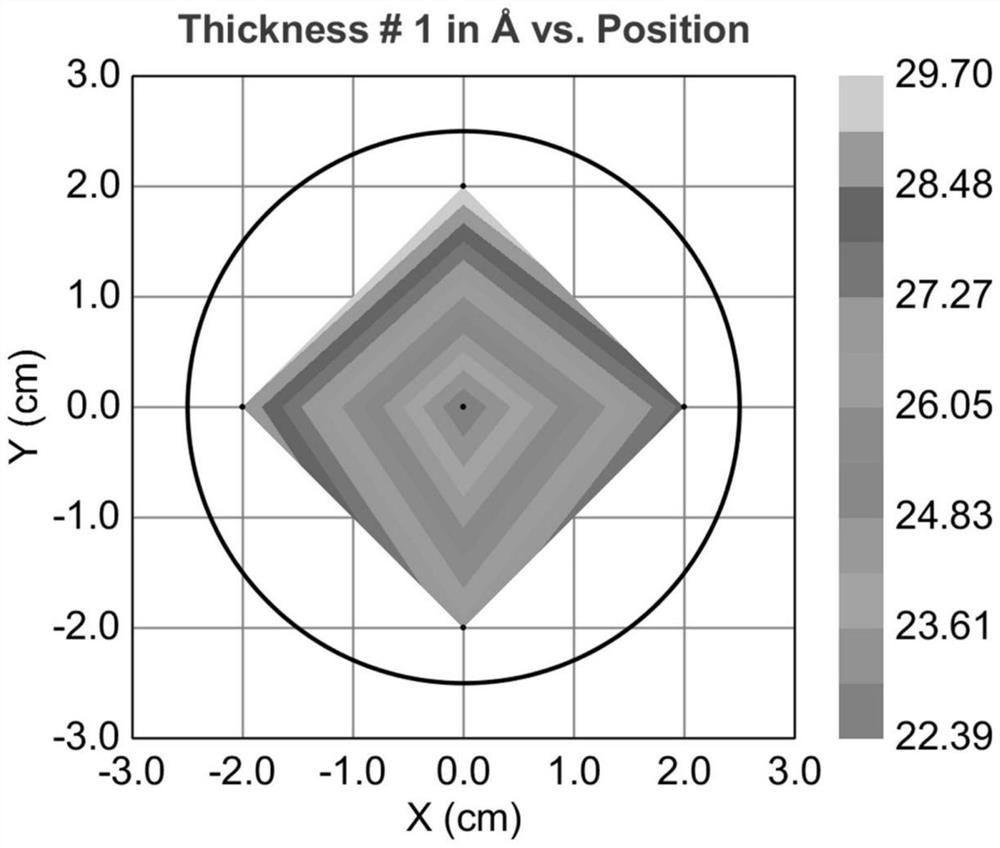

example 1

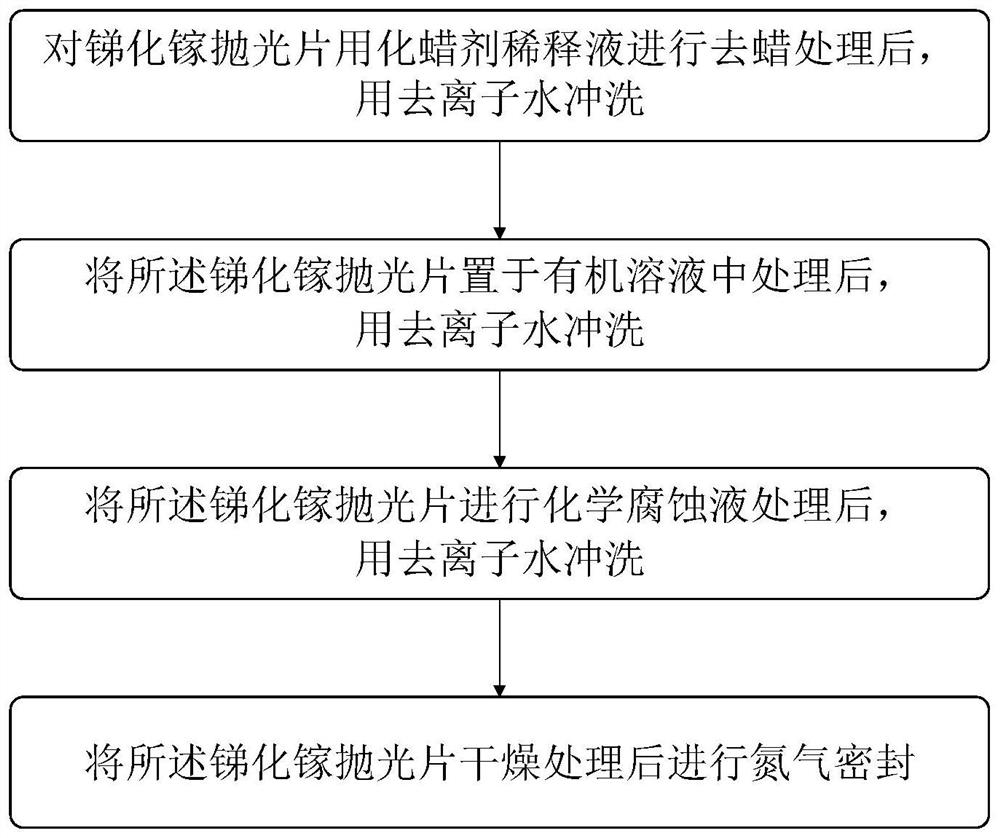

[0035] The method for controlling the thickness of the oxide layer on the surface of the gallium antimonide single crystal includes: treating the gallium antimonide polished piece with a diluent of wax remover, an organic solution and a chemical corrosion solution, specifically, including:

[0036] S1: After immersing the gallium antimonide polished wafer in a diluent of wax remover (40% wax remover) at 85°C for 1 min, take it out and spray and rinse the gallium antimonide wafer surface with deionized water for 40 seconds;

[0037] S2: Place the gallium antimonide polished sheet obtained in S1 in isopropanol solution at 25°C for 30s, and rinse with deionized water for 20s;

[0038] S3: Soak the gallium antimonide polished sheet obtained in S2 in a chemical etching solution at 20°C for 1 minute, and then rinse it with deionized water for 20 seconds, wherein the composition of the chemical etching solution is deionized water with a volume fraction of 78%, Volume fraction is 2% hyd...

example 2

[0055] The method for controlling the thickness of the oxide layer on the surface of the gallium antimonide single crystal includes: treating the polished gallium antimonide sheet with a diluent of wax remover, an organic solution and a chemical corrosion solution, specifically, including:

[0056] S1: After immersing the gallium antimonide polished wafer in 80°C waxing agent diluent (the waxing agent content is 40%) for 1 min, take it out and spray and rinse the gallium antimonide wafer surface with deionized water for 60 seconds;

[0057] S2: Place the gallium antimonide polished sheet obtained in S1 in isopropanol solution at 25°C for 1 min, and rinse with deionized water for 40 s;

[0058] S3: After immersing the gallium antimonide polished sheet obtained in S2 in a chemical etching solution at 20°C for 1 minute, rinse it with deionized water for 40 seconds, wherein the composition of the chemical etching solution is deionized water with a volume fraction of 78%, Volume fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com