Ternary composite gas sensor and preparation method thereof

A gas sensor, ternary composite technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of unfavorable gas sensing performance of polyaniline, easy aggregation and entanglement of carbon tubes, and improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method for a ternary composite gas sensor, comprising the following steps:

[0051] 1) disperse 5 mg of hydroxylated multi-walled carbon nanotubes into 20 ml of tan graphene oxide aqueous dispersion (concentration is 0.5 mg / ml), and reach a uniform and stable state after ultrasonic treatment for 30 minutes; the obtained oxidation The graphene / hydroxylated multi-walled carbon nanotube aqueous dispersion was transferred to a sealed Teflon-lined stainless steel autoclave, which was placed in a heating box at 180 °C for about 18 After the reaction was completed, it was left to stand and naturally cooled to room temperature; the obtained reduced graphene oxide / hydroxylated multi-walled carbon nanotube suspension was taken out from the reactor, washed with deionized water and ethanol for several 3 to 5 times; finally, after drying under vacuum conditions at 60°C, the reduced graphene oxide / hydroxylated multi-walled carbon nanotube composite powder is obtained; ...

Embodiment 2

[0056] A preparation method for a ternary composite gas sensor, comprising the following steps:

[0057] 1) Disperse 15 mg of hydroxylated multi-walled carbon nanotubes into 30 ml of tan graphene oxide aqueous dispersion (concentration is 0.5 mg / ml), and reach a uniform and stable state after ultrasonic treatment for 60 minutes; the obtained oxidation The graphene / hydroxylated multi-walled carbon nanotube aqueous dispersion was transferred to a sealed Teflon-lined stainless steel autoclave, which was placed in a heating oven at 220 °C for about 12 After the reaction was completed, it was left to stand and naturally cooled to room temperature; the obtained reduced graphene oxide / hydroxylated multi-walled carbon nanotube suspension was taken out from the reactor, washed with deionized water and ethanol for several 3 to 5 times; finally, after drying under vacuum conditions at 60°C, the reduced graphene oxide / hydroxylated multi-walled carbon nanotube composite powder is obtained;...

Embodiment 3

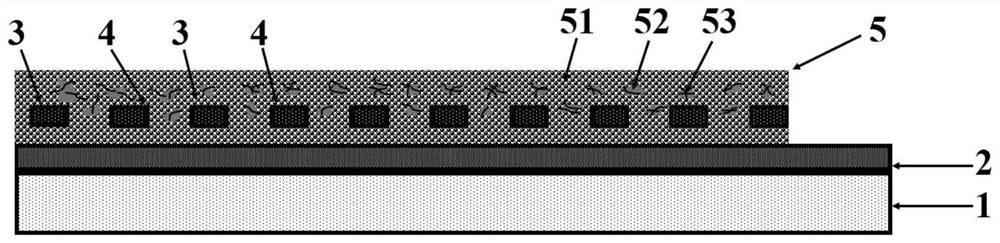

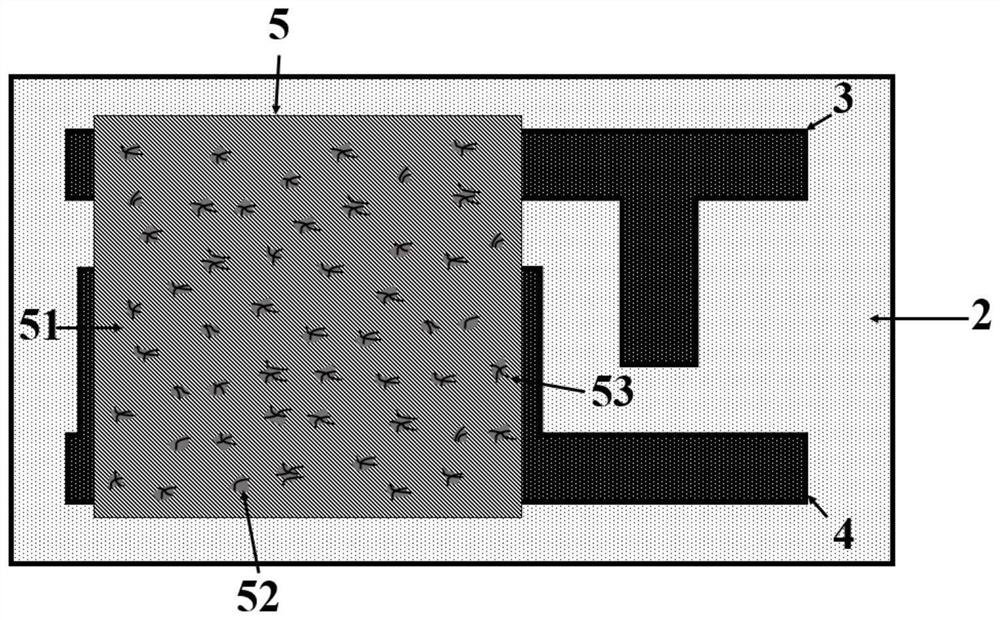

[0065] A kind of ternary compound gas sensor, refer to figure 1 , figure 2 , which includes a silicon substrate 1 at the bottom of the sensor, a silicon dioxide film 2 above the silicon substrate 1, and a first electrode 3 and a second electrode 4 on the surface of the silicon dioxide film 2, the first electrode 3, the second electrode Reduced graphene oxide / hydroxylated multi-walled carbon nanotubes / polyaniline ternary composite film 5 attached between 4 and its upper surface.

[0066] Further, the reduced graphene oxide / hydroxylated multi-walled carbon nanotubes / polyaniline ternary composite film 5 is composed of reduced graphene oxide sheets 52 , hydroxylated multi-walled carbon nanotubes 53 and polyaniline 51 .

[0067] As a preferred implementation manner, the electrode pattern in the electrode substrate is in the shape of a staggered comb.

[0068] Further, the distance between adjacent first electrodes 3 and second electrodes 4 is 10-80 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com