Fourier transform infrared spectrum measuring device for in-situ monitoring of chemical and chemical reaction

A technology of Fourier transform and infrared spectroscopy, applied in the field of instruments and meters, can solve the problems of slow heating rate, inconvenient reaction mechanism research, and many side reactions, and achieve the effects of fast temperature change rate, high modularization degree, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

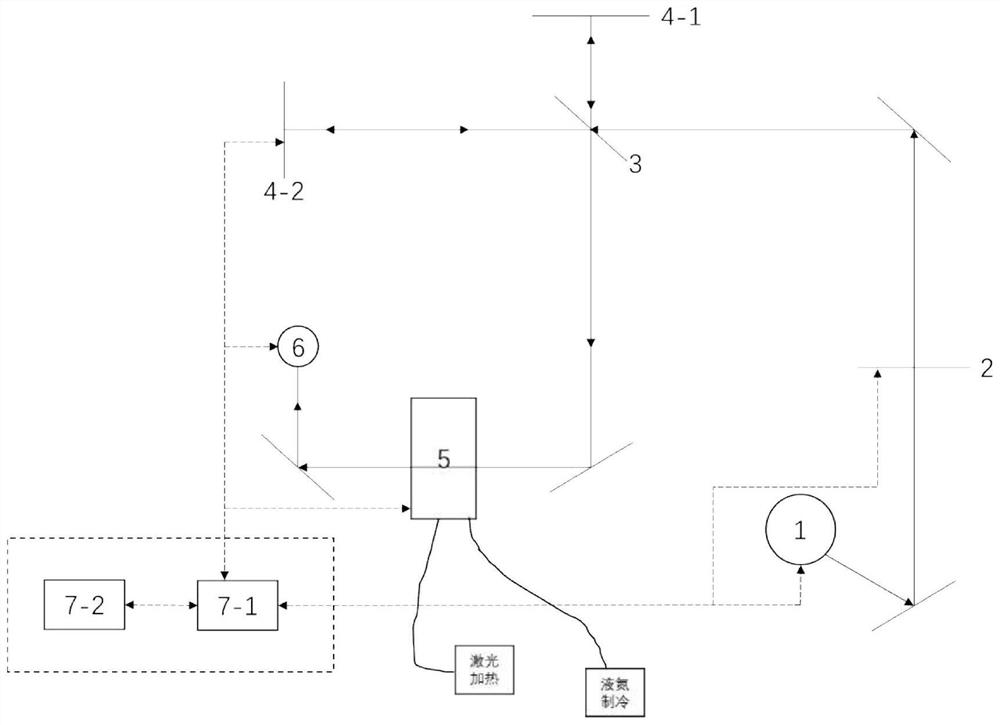

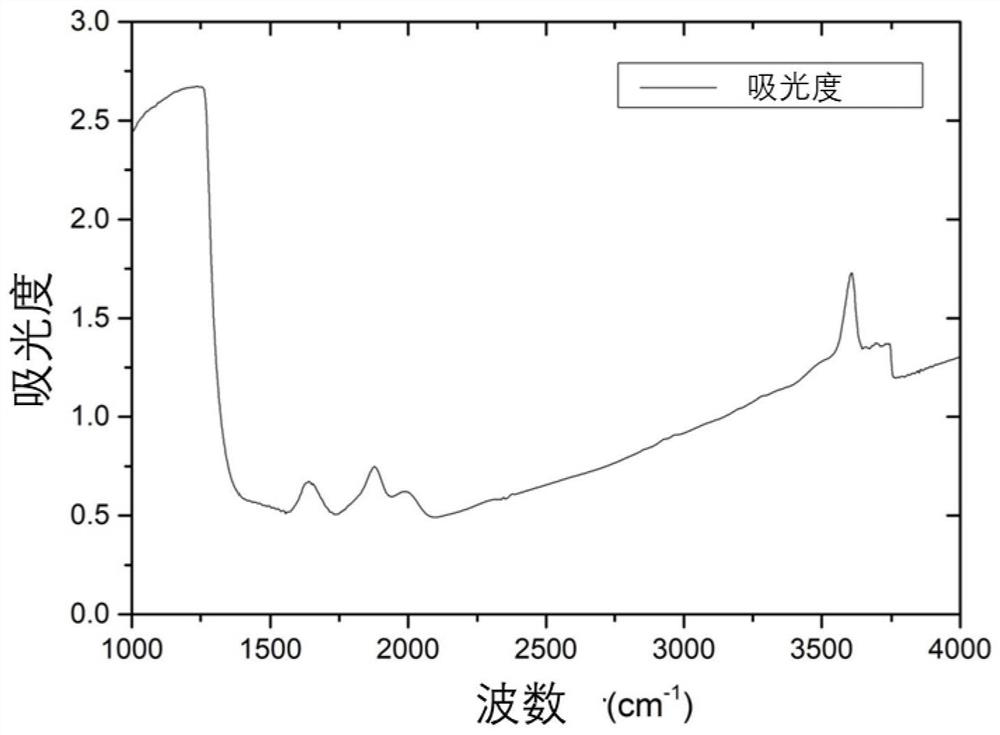

[0046] The experimental sample is an acidic molecular sieve. First, measure the infrared spectrum of the background environment. The general control 7-1 of the instrument controls the infrared light source 1 to emit infrared light, and controls the aperture 2 to a suitable size. The infrared light enters the beam splitter 3 after reflection and is divided into two beams. , enter the interferometer 4, control the movement of the moving mirror 4-2 of the interferometer, the infrared light enters the sample cell 5 without samples after interference, and the detector 6 collects light intensity data at different optical paths and feeds it back to the overall control of the instrument 7-1 , and then feed back to the computer 7-2 to perform Fourier transform on the optical path difference to obtain the infrared spectrum of the blank background, and deduct the influence of water vapor, carbon dioxide and other gases on the sample test; then measure the infrared sample of the acidic mole...

Embodiment 2

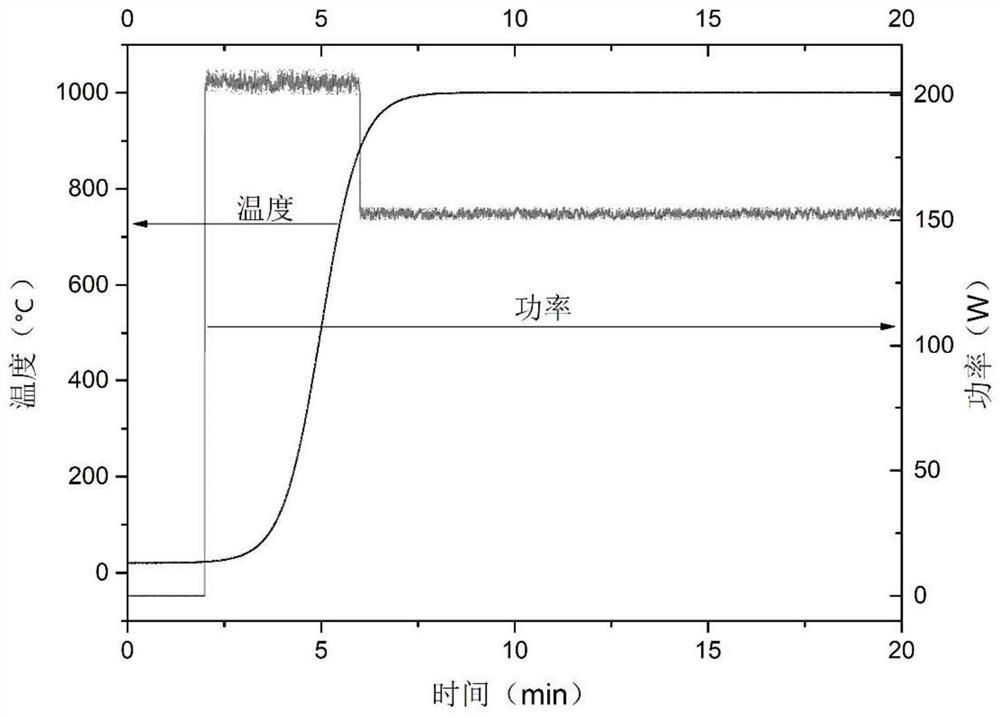

[0048] Test the linkage between the in-situ reaction cell and the laser heating module and the liquid nitrogen cooling module. image 3 It shows the temperature change and power change curve of the in-situ reaction pool laser heating module of this product. The laser heating starts at 2 minutes, and the power rises rapidly to 200W, which can quickly rise to 1000°C in a short period of time, and then maintain at a power of 150W. Constant temperature; Figure 4 It shows the temperature change and injection volume curve of the in-situ reaction pool liquid nitrogen cooling module of this product. Liquid nitrogen is injected at a constant speed, and the temperature drops rapidly to -180°C and remains at this temperature for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com