Device for achieving rapid heat circulation and use method of device

A heat cycle and fast technology, applied in the field of heat treatment, can solve the problems of large difference in actual conditions and weak output capacity, and achieve the effects of controllable temperature range, fast temperature change rate and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

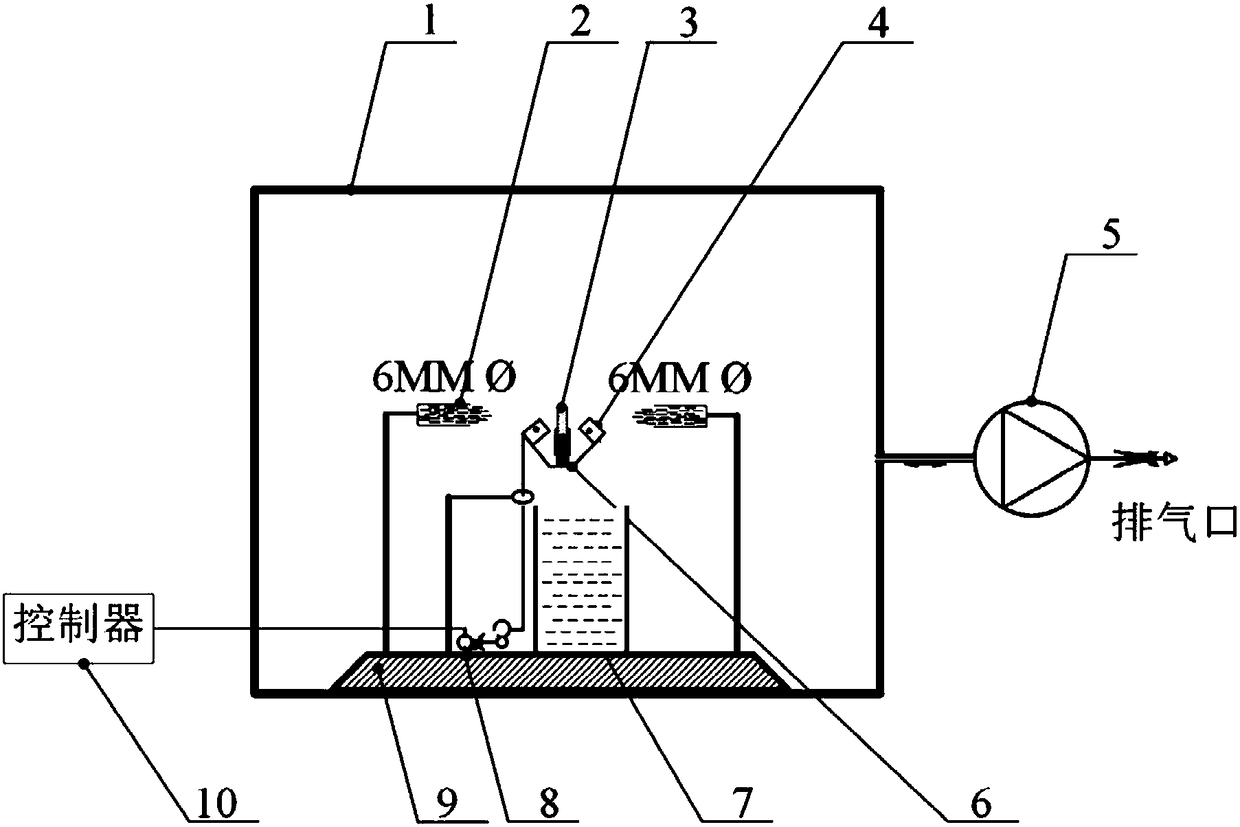

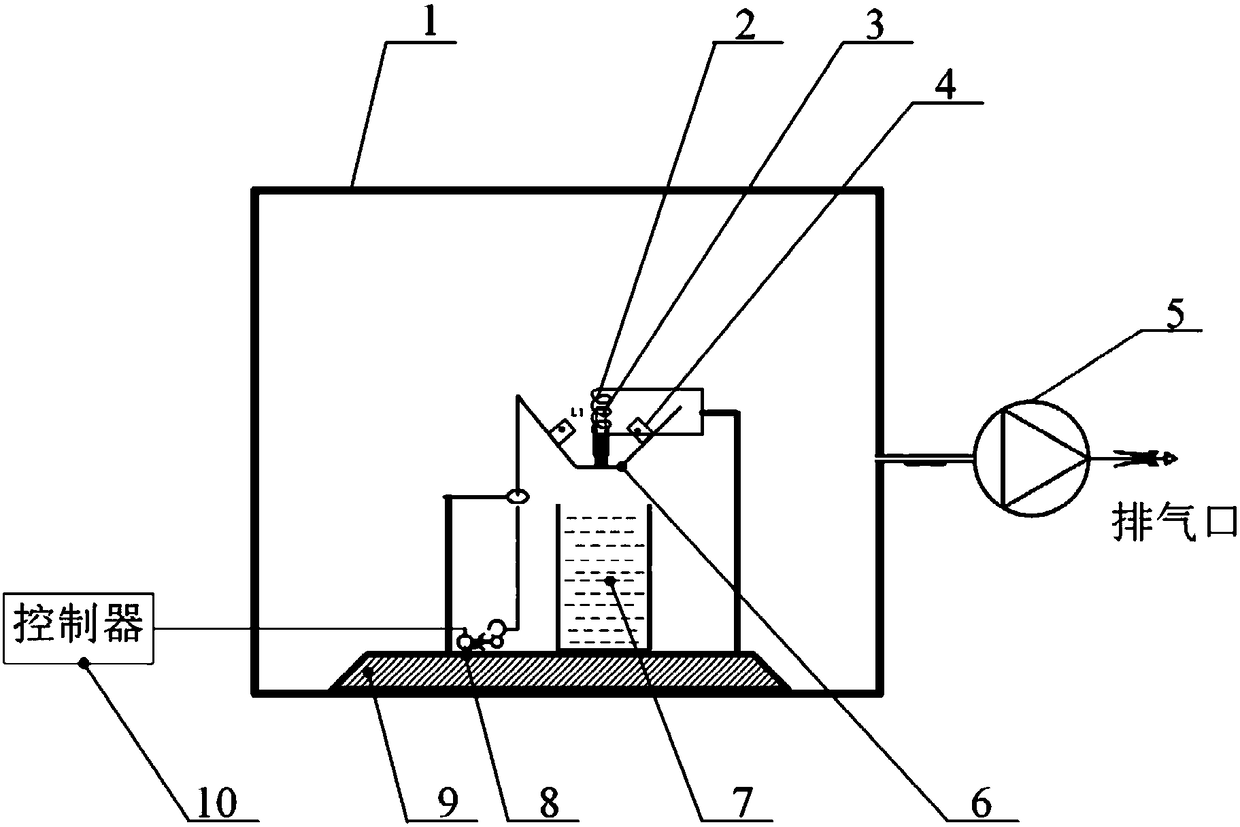

[0024] see figure 1 and figure 2 , the present invention realizes the device of rapid heat cycle, comprises stainless steel frame body 1, torch heating heat source 2, test piece 3, cleaning device 4, pump 5, test piece clamping arm 6, medium container 7, motor 8, base 9 and The controller 10; the base 9 is fixed on the ground or inside the stainless steel frame body 1, the motor 8 and the medium container 7 are fixed on the base 9, the heating heat source 2 and the specimen clamping arm 6 are fixed on the bracket connected to the base, and the heating heat source 2 Blowtorches or induction coils are used; the test piece 3 and the cleaning device 4 are fixed on the movable part of the test piece holding arm 6, the pump 5 is connected to the frame body 1, the motor 8 and the cleaning device 4 are connected to the controller through the data line and controlled by its a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com