Flexible sensing layer, preparation method of flexible sensor and flexible sensor

A flexible sensor and sensing layer technology, applied in the field of sensors, can solve the problems of low sensing sensitivity of the sensing layer, mutual interference between resistance and pyroelectric voltage signals, etc., so as to improve the carrier concentration, improve the Seebeck coefficient, and increase the internal Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

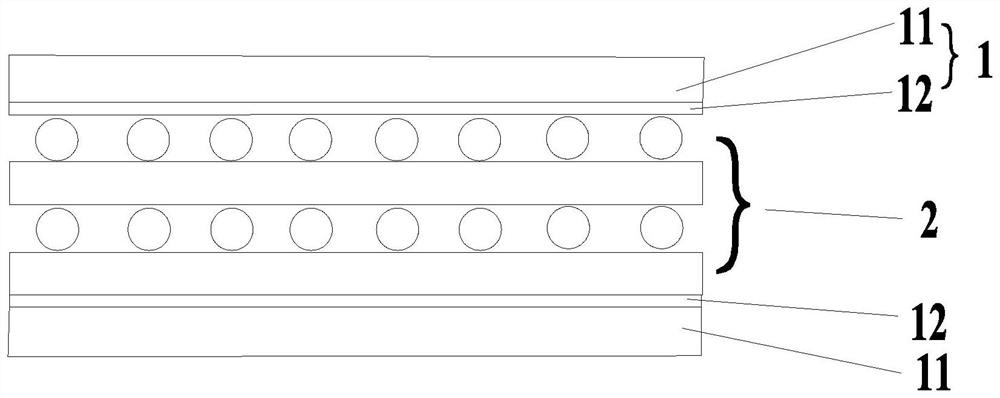

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a flexible sensing layer, comprising the following steps:

[0038] Step S1: using 3D printing technology to prepare a flexible sensing layer substrate with a multi-level sub-pore structure;

[0039] Step S2: adding a thermoelectric material coating on the surface of the flexible sensing layer substrate;

[0040] Step S3: performing plasma treatment on the surface of the thermoelectric material coating to obtain a flexible sensing layer 2 .

[0041] The embodiment of the present invention uses 3D printing technology to prepare a flexible sensing layer matrix with a multi-level sub-pore structure, and increases the internal contact area of the flexible sensing layer matrix with a multi-level sub-pore structure under the action of pressure, thereby increasing the resistance. The range of change increases the pressure sensitivity of the flexible sensing layer 2; the temper...

Embodiment 1

[0075] The preparation method of the flexible sensing layer 2 in this embodiment is as follows:

[0076] First, mix degradable thermoplastic polyurethane and ethanol at a mass ratio of 1:1, then add carbon nanofibers with a mass ratio of 1:100 to thermoplastic polyurethane and 50 carbon nanofibers with a mass ratio of 4.5:1 to thermoplastic polyurethane. Micron salt particles, ie NaCl particles, were stirred and debubbled for 5 minutes at a rotation speed of 2000 rpm using a planetary mixing mixer to obtain a printing paste.

[0077] combine figure 2 and image 3 As shown, the printing paste prepared above is placed in the printing needle tube of the direct-writing printer, the inner diameter needle of 600 microns is configured, the extrusion rate is controlled at 5.6mm / s, and 4 layers of printing are stacked, and the printed 4 layers are stacked The flexible sensing layer substrate was placed in a 20°C vacuum oven for 2 hours to completely remove ethanol, and then the flex...

Embodiment 2

[0081] The preparation method of the flexible sensor in this embodiment includes the flexible sensing layer 2 described in Embodiment 1, specifically as follows:

[0082] Disperse 0.08g of nano-silver flakes with a diameter of 5 microns in 20ml of ethanol, use an ultrasonic probe to treat it at a power of 100W for 10 minutes, pour it into a suction filter container, and use polyvinylidene fluoride with a pore size of 0.22 microns and a diameter of 50 mm The filter membrane was filtered by a circulating vacuum pump, and the filtered filter membrane was placed in a vacuum oven at 20° C. and dried for 1 hour.

[0083] A degradable thermoplastic polyurethane film with a thickness of 120 microns was prepared on a glass plate by a doctor blade method, and placed in a vacuum oven at 120° C. for 30 minutes to make the thermoplastic polyurethane film reach a semi-cured state.

[0084] Put the nano-silver sheet / polyvinylidene fluoride film with the nano-silver sheet on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com