Multilayer proton exchange membrane for water electrolysis and preparation method thereof

A proton exchange membrane, water electrolysis technology, applied in the electrolysis process, electrolysis components, organic diaphragms, etc., can solve the problems of poor proton conductivity, short life, performance degradation of the proton exchange membrane, etc., to achieve low price, low cost, and avoid deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

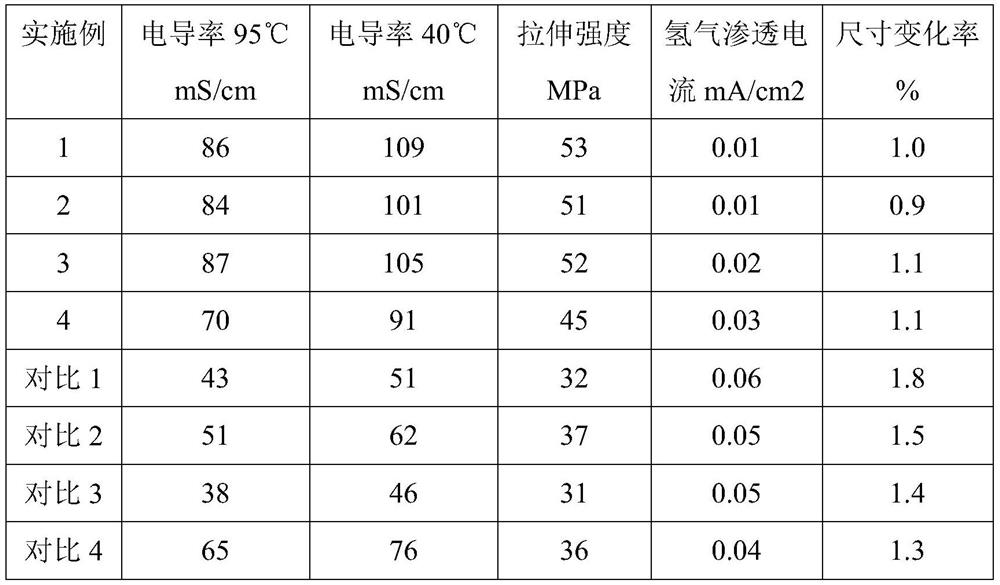

Examples

Embodiment 1

[0033] (1) Weigh 50 g of long side chain perfluorosulfonic acid resin, add 225 mL of deionized water and 225 mL of isopropanol, and stir at room temperature for 20 h to obtain a long side chain perfluorosulfonic acid resin solution with a solubility of 10%;

[0034] (2) Weigh 1g side chain molecular structure as -OCF 2 CF 2 SO 3 For the short side chain perfluorosulfonic acid resin of H, add 99mL of deionized water, stir at room temperature for 50h, and obtain a short side chain perfluorosulfonic acid resin solution with a concentration of 1%.

[0035] (3) Install the release-type polyethylene terephthalate (PET) base film with a thickness of 5 μm in a continuous coating equipment, and then use a coating speed of 1 m / min, a coating wet thickness of 1000 μm, and a coating pressure of 0.1 Process parameters of bar Coat the long-side-chain perfluorosulfonic acid resin solution prepared in step (1) on the surface of the basement membrane, and dry it through oven A at 50°C to for...

Embodiment 2

[0042] (1) Weigh 200g of long side chain perfluorosulfonic acid resin, add 50mL of deionized water and 250mL of ethanol, stir at room temperature for 50h, and obtain a long side chain perfluorosulfonic acid resin solution with a solubility of 40%;

[0043] (2) Weigh 10g side chain molecular structure as -OCF 2 CF 2 CF 2 SO 3 For the short side chain perfluorosulfonic acid resin of H, add 990mL of ethanol and stir at room temperature for 20h to obtain a short side chain perfluorosulfonic acid resin solution with a concentration of 1%.

[0044] (3) Install a release-type polyethylene naphthalate (PEN) base film with a thickness of 50 μm in a continuous coating equipment, and then use a coating speed of 10 m / min, a coating wet thickness of 100 μm, and a coating pressure of 0.01 bar The process parameters of the long side chain perfluorosulfonic acid resin solution prepared in step (1) are coated on the surface of the basement membrane, and dried by drying tunnel A at 30°C to f...

Embodiment 3

[0051] (1) Weigh 100g of long side chain perfluorosulfonic acid resin, add 100mL of deionized water and 300mL of n-propanol, stir at room temperature for 40h, and obtain a solution of long side chain perfluorosulfonic acid resin with a solubility of 20%;

[0052] (2) Weigh 20g side chain molecular structure as -OCF 2 SO 3 For the short side chain perfluorosulfonic acid resin of H, add 380mL n-propanol, stir at room temperature for 40h, and obtain a concentration of 5% short side chain perfluorosulfonic acid resin solution;

[0053] (3) Install the release polyethylene film (PE) base film with a thickness of 20 μm in a continuous coating equipment, and then adopt the process parameters of coating speed 5m / min, coating wet thickness 500 μm, coating pressure 0.05bar (1) The long side chain perfluorosulfonic acid resin solution prepared is coated on the surface of the basement membrane, and dried by drying tunnel A at 40° C. to form a gel state long side chain perfluorosulfonic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com