High-strength magnesium refractory mortar for refining steel ladle

A high-strength refractory mud technology, which is applied in the field of refined ladle refractory mud, can solve the problems of brick joints being easily corroded, and achieve the effects of enhanced erosion resistance and permeability, high strength, and reduced water addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

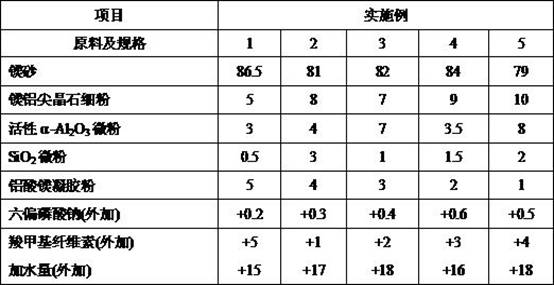

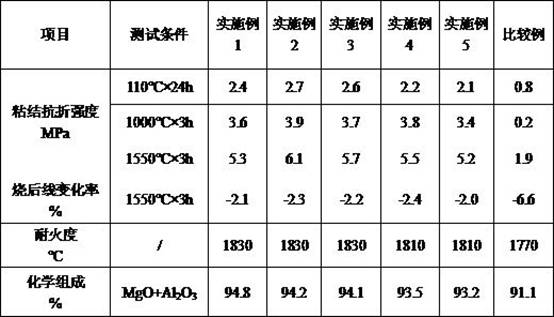

[0024] A high-strength magnesia refractory mud for refining ladles, the raw materials of the refractory mud include: 79-87% of magnesia, 5-10% of aluminum-magnesium spinel fine powder, active α-Al 2 o 3 Micropowder 3~8%, SiO 2 Micropowder 0.5-3%, magnesium aluminate gel powder 1-5%; plus sodium hexametaphosphate + 0.2-0.6%, carboxymethyl cellulose + 1-5%. Since the various refractory bricks used for masonry and refining ladles mainly involve magnesia, aluminum, and magnesia-aluminum refractory bricks, and the service temperature exceeds 1600°C, the chemical composition of the refractory mud in the present invention is mainly MgO. The brick has good bonding performance, high strength, good resistance to high-temperature molten steel erosion, and less low-melt in the composition, and has better high-temperature resistance, and the chemical composition of refractory mud is more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com