Method for preparing metal-nitrogen molecule/graphene/carbon nanofiber composite material through electrostatic spinning and application of metal-nitrogen molecule/graphene/carbon nanofiber composite material

A technology of carbon nanofibers and electrospinning, applied in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve problems such as increased cost, unevenness, weak adhesion of coated catalysts, etc., and achieve enhanced stability , the effect of strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Preparation of metal-nitrogen molecule\polyacrylonitrile composite nanofiber membrane material

[0059] 1. Add 0.5g of heme iron into 20g of N-N dimethylformamide solvent, stir at room temperature to make it evenly distributed, and obtain a tan solution, then add 1.28g of polyacrylonitrile (accounting for the mass of N-N dimethylformamide 6%), stirred vigorously at room temperature for 12 hours to obtain a viscous spinning solution.

[0060] 2. Put the precursor solution into the container box containing the spinning solution, set the distance between the wires to 15cm, the scanning speed of the container box to 30mm / min, the ambient humidity to about 30% RH, and the applied voltage to 24kV. spinning to obtain Fe-N / polyacrylonitrile composite nanofiber membrane material.

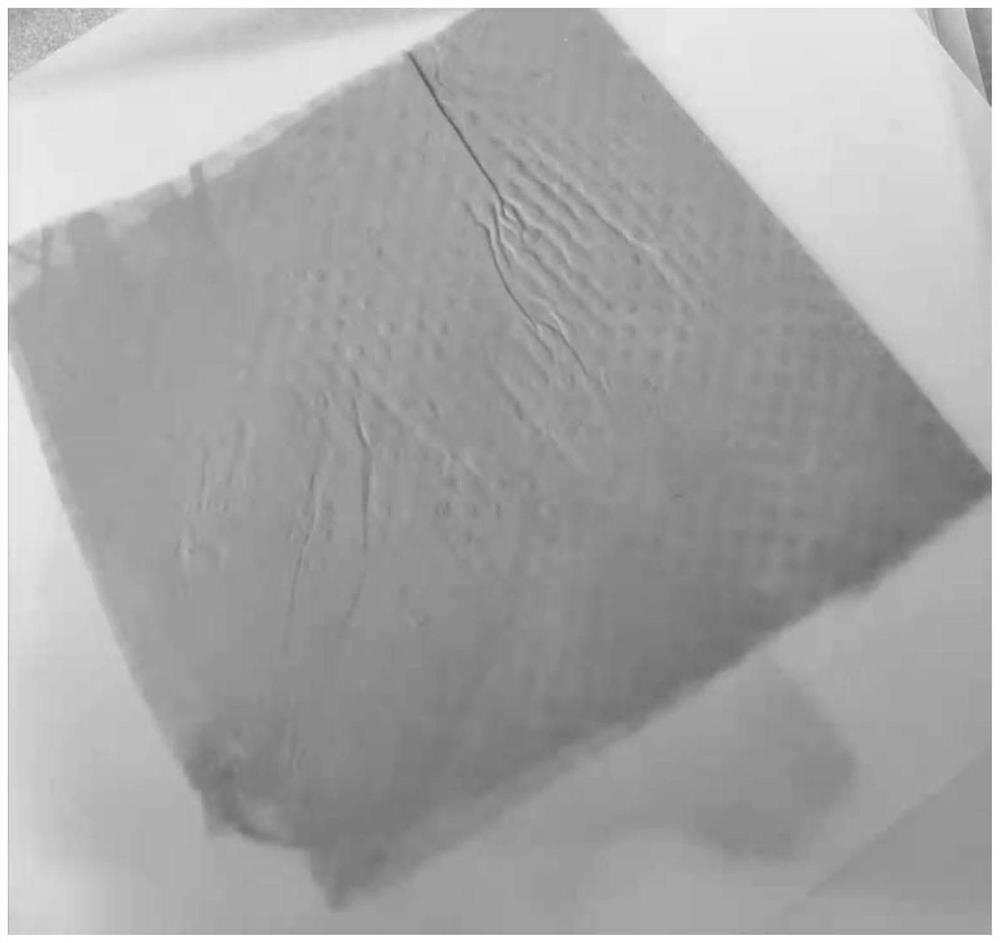

[0061]3. Place the obtained Fe-N / polyacrylonitrile nanofiber membrane material in a vacuum oven and dry it at 80°C for 12 hours to remove the residual DMF organic solvent. The optical phot...

Embodiment 2

[0062] Embodiment 2: catalytic reaction

[0063] 1. Pretreat the Fe-N / polyacrylonitrile nanofiber membrane material prepared in Example 1 under an air atmosphere. The pretreatment temperature is 280°C, the pretreatment time is 2h, and the heating rate is 5°C / min. After the temperature was lowered to room temperature, the pretreated Fe-N / polyacrylonitrile nanofiber membrane was obtained. The tensile strength of the composite film is 35MPa according to the film strength measurement by a universal mechanical instrument.

[0064] 2. Place the pretreated Fe-N / polyacrylonitrile nanofiber membrane in an ammonia atmosphere for carbonization treatment. The carbonization temperature is 1050°C, the carbonization time is 1h, and the heating rate is 5°C / min. Fe -N / carbon nanofiber membrane as ORR, CO 2 RR catalyst. The tensile strength of the catalyst membrane after heat treatment was 21 MPa.

[0065] 3. ORR catalytic performance test

[0066] A circular die with a diameter of 5 mm wa...

Embodiment 3

[0070] Embodiment 3: catalytic reaction

[0071] 1. Pretreat the Fe-N / polyacrylonitrile nanofiber membrane material prepared in Example 1 under an air atmosphere. The pretreatment temperature is 280°C, the pretreatment time is 2h, and the heating rate is 5°C / min. After the temperature was lowered to room temperature, the pretreated Fe-N / polyacrylonitrile nanofiber membrane was obtained.

[0072] 2. Place the pretreated Fe-N / polyacrylonitrile nanofiber membrane under an argon atmosphere for carbonization treatment. The carbonization temperature is 1050°C, the carbonization time is 1h, and the heating rate is 5°C / min. Fe -N / carbon nanofiber membrane as ORR, CO 2 RR catalyst. The difference between this and Example 2 is that the carbonization treatment atmosphere is different.

[0073] 3. ORR catalytic performance test

[0074] A circular die with a diameter of 5 mm was used to press a disc with a diameter of 5 mm from the Fe-N / carbon nanofiber membrane as a catalyst for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com