Special-shaped mica insulation product suitable for three-dimensional modeling and preparation method of special-shaped mica insulation product

A mica insulation, three-dimensional technology, applied in the direction of mica, insulators, inorganic insulators, etc., can solve the problems of poor toughness of mica products and limit the application fields of mica products, etc., achieve high heat resistance, facilitate industrial batch production, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0043] The preparation method of zirconia: 1.0L of 10% sodium hydroxide solution is added to the stirring and grinding machine, and then 50g of zirconium oxychloride (Aladdin) is gradually added to the sodium hydroxide solution in the stirring and grinding machine, and the temperature is controlled At 4°C, stir and grind at 60 rpm for 60 minutes to obtain the mixture, let it settle for 2 hours, wash and filter with ethanol, and dry to obtain a semi-finished product. Put the semi-finished product in a planetary ball mill and ball mill it at 50 rpm for 20 minutes to obtain zirconia powder. The obtained zirconia powder was calcined at 1050°C±5°C for 1.5h, and cooled naturally to obtain t-phase zirconia.

preparation example 2

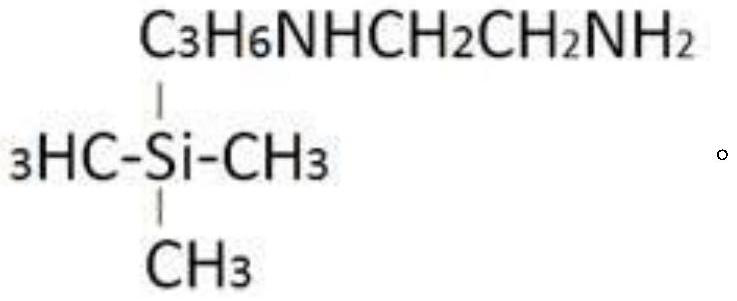

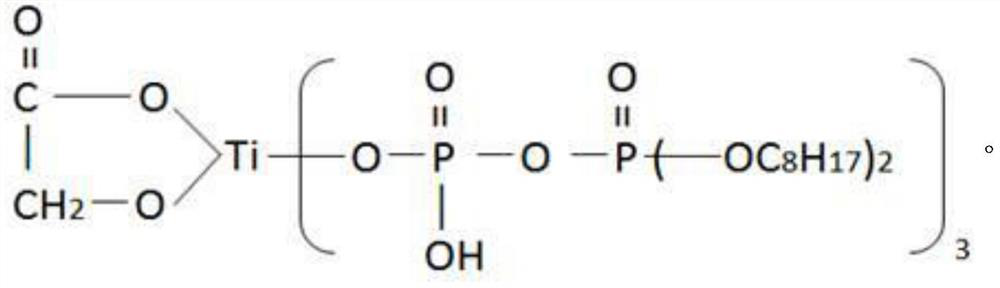

[0045] The silicone resin is prepared from 18g of FM-7721 modified hydroxysiloxane, 49.6g of methanol, 32g of KR-242A silicone resin and 0.2g of diethylenetriamine.

[0046] The preparation method of silicone resin: add 0.05g of diethylenetriamine, 18g of FM-7721 modified hydroxysiloxane and 32g of methylphenyl silicone resin into the reaction kettle, pre-react at 65°C for 120s, cool down After reaching 4°C, add 49.6 g of methanol, stir at 80 rpm for 10 min, add 0.15 g of diethylenetriamine, and stir at 60 rpm for 2 min to obtain a finished silicone resin.

preparation example 3

[0048] The silicone resin is prepared from 18g of FM-7725 modified hydroxysiloxane, 49.6g of methanol, 32g of KR-242A silicone resin and 0.2g of diethylenetriamine.

[0049] The preparation method of silicone resin: add 0.05g of diethylenetriamine, 18g of FM-7725 modified hydroxysiloxane and 32g of KR-242A silicone resin into the reaction kettle, pre-react at 65°C for 120s, cool down After reaching 4°C, add 49.6 g of methanol, stir at 80 rpm for 10 min, add 0.15 g of diethylenetriamine, and stir at 60 rpm for 2 min to obtain a finished silicone resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com