Waveform asphalt shingle and preparation method thereof

A technology of asphalt tiles and corrugated tiles, applied to roofs, roofs, buildings, etc. that use tiles/slate tiles, can solve problems such as easy fading, failure to achieve the expected effect of the roof, and poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

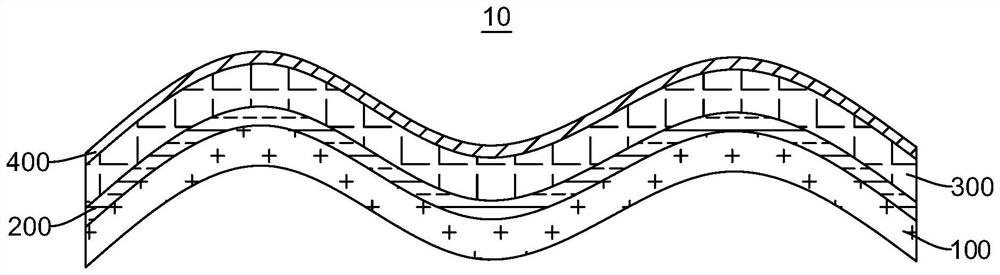

[0030] The embodiment of the present application provides a method for preparing a corrugated asphalt tile, which includes: firstly setting an adhesive on the water-facing surface of the dried corrugated asphalt tile substrate to form a first glue layer, and then setting sintered colored sand on the surface of the first glue layer A colored sand layer is formed, and then an adhesive is placed on the surface of the colored sand layer to form a second adhesive layer.

[0031] The corrugated asphalt shingle base plate has a thickness of ≥3mm, a water absorption rate of ≤20%, an asphalt content of ≥40%, and a water content of ≤15%.

[0032] It should be noted that the thickness of the corrugated asphalt shingle substrate is selected according to the size and requirements of the corrugated asphalt shingle substrate.

[0033] In one embodiment of the present application, the corrugated asphalt shingle substrate has a thickness of 3mm. In some other embodiments of the present applic...

Embodiment 1

[0068] The embodiment of the present application provides a corrugated asphalt tile and its preparation method, which includes the following steps:

[0069] Select a corrugated asphalt tile substrate with a thickness of 3mm, a water absorption rate of ≤20%, an asphalt content of ≥40% and a water content of ≤15%. The amount of adhesive for the adhesive layer is 650g / m 2 , and then sprinkle dark red sintered colored sand with mesh number of 40-120 on the surface of the first glue layer to form a colored sand layer, and the amount of sintered colored sand to form the colored sand layer is 1500g / m 2 , and then coated with acrylic emulsion on the surface of the colored sand layer to form a second adhesive layer to obtain a preform, the amount of adhesive used to form the second adhesive layer is 350g / m 2 , the preform was dried at 150°C for 4 hours to obtain corrugated asphalt tiles, such as figure 2 shown.

Embodiment 2

[0071] The embodiment of the present application provides a corrugated asphalt tile and its preparation method, which includes the following steps:

[0072] Select a corrugated asphalt tile substrate with a thickness of 3mm, a water absorption rate of ≤20%, an asphalt content of ≥40% and a water content of ≤15%. The amount of adhesive for the adhesive layer is 650g / m 2 , and then sprinkle dark red sintered colored sand with mesh number of 40-120 on the surface of the first glue layer to form a colored sand layer, and the amount of sintered colored sand to form the colored sand layer is 1500g / m 2 , and then coated with acrylic emulsion on the surface of the colored sand layer to form a second adhesive layer to obtain a preform, the amount of adhesive used to form the second adhesive layer is 350g / m 2 , place the prefab in a rainproof place to dry naturally, and make corrugated asphalt tiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com