A kind of vitrified glass glue and preparation method thereof

A technology of glass glue and porcelain, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of not being too high in temperature, short service life, and limiting the use of glass glue, so as to improve construction speed, Long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

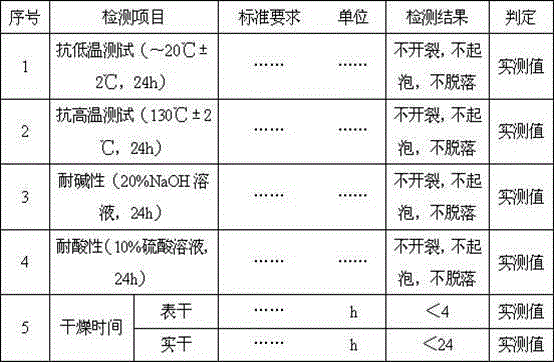

Image

Examples

preparation example Construction

[0021] A preparation method of vitrified glass glue, comprising the steps of:

[0022] (1) Preparation of component A: Weigh epoxy resin, thickening filler and auxiliary agent in parts by weight, put each raw material into the reaction kettle at room temperature, stir while raising the temperature, and the heating rate is 5-8 °C / min, when the temperature in the kettle reaches 65-80 °C, stop stirring, and keep warm for 30-60 minutes to obtain the finished epoxy glue; if necessary, 0.5-20 parts by weight of pearl powder can also be added to the raw materials Or 0.5-10 parts by weight of titanium dioxide.

[0023] (2) Preparation of component B: Weigh the amine curing agent, thickening material and auxiliary agent in parts by weight, put each raw material into the reaction kettle at room temperature, stir while heating up, and the heating rate is 5 ~8°C / minute, when the temperature in the kettle reaches 65-80°C, stop stirring, keep warm for 30-60 minutes to get the finished cure...

Embodiment 1

[0033] formula:

[0034] Component A: 80 parts of epoxy resin, 10 parts of bentonite with 180 meshes, 0.8 parts of polypropylene glycol diglycidyl ether

[0035] Component B: 30 parts of amine curing agent, 5 parts of 800 mesh talc powder, 0.3 parts of silicone defoamer

[0036] Preparation:

[0037] (1) Preparation of component A: Weigh the epoxy resin, thickening filler and auxiliary agent respectively by weight, put each raw material into the reaction kettle at room temperature, stir while raising the temperature, and the heating rate is 5°C / Minutes, when the temperature in the kettle reaches 65°C, stop stirring, and keep warm for 60 minutes to get the finished epoxy glue;

[0038] (2) Preparation of component B: Weigh the amine curing agent, thickening material and auxiliary agent in parts by weight, put each raw material into the reaction kettle at room temperature, stir while heating up, and the heating rate is 5 °C / min, when the temperature in the kettle reaches 65 ...

Embodiment 2

[0041] formula:

[0042] Component A: 90 parts of epoxy resin, 30 parts of silicon micropowder with 200 meshes, 9 parts of dibutyl ester, 0.5 parts of pearl powder

[0043] Component B: 45 parts of amine curing agent, 20 parts of 3000 mesh talc powder, 3 parts of silicone defoamer

[0044] Preparation:

[0045](1) Preparation of component A: Weigh epoxy resin, thickening filler and auxiliary agent according to parts by weight, put each raw material into the reaction kettle at room temperature, stir while raising the temperature, and the heating rate is 5°C / Minutes, when the temperature in the kettle reaches 70°C, stop stirring, and keep warm for 50 minutes to get the finished epoxy glue;

[0046] (2) Preparation of component B: Weigh the amine curing agent, thickening material and auxiliary agent in parts by weight, put each raw material into the reaction kettle at room temperature, stir while raising the temperature, and the heating rate is 6 °C / min, when the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com