Recovery method and application of alpha-chloro-alpha-acetyl-gamma-butyrolactone layered water

A kind of recovery method, the technology of acetyl group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

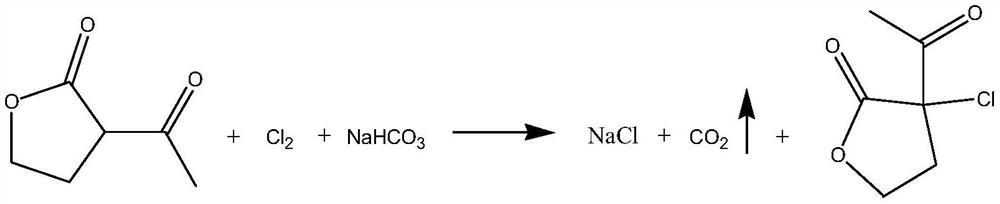

Method used

Image

Examples

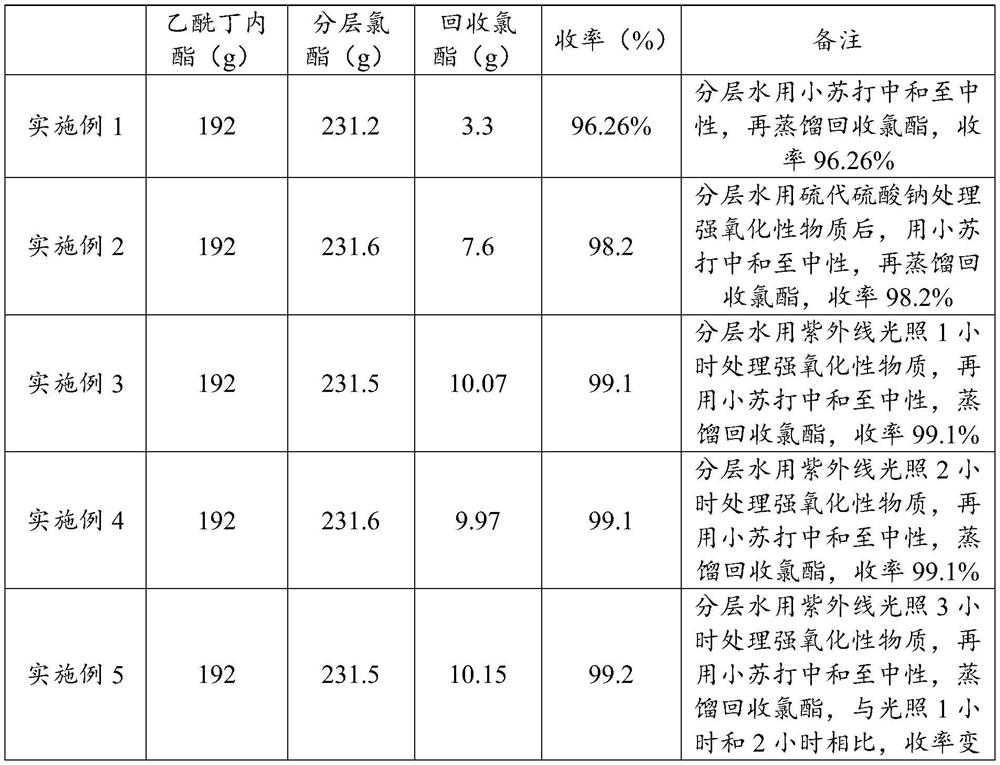

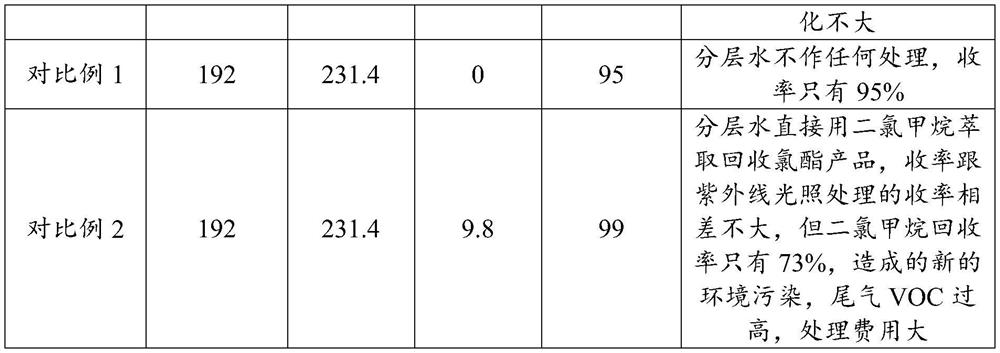

Embodiment 1

[0054] (a) 192g of α-acetyl-γ-butyrolactone, 125g of baking soda and 252g of water are put into the reaction equipment, the temperature is controlled within 18°C, and then 110g of chlorine gas is fed into the reaction, and the reaction is left to stand for stratification. Obtain product α-chloro-α-acetyl-γ-butyrolactone 231.2g and layered water 377.8g;

[0055] (b) After adjusting the obtained layered water to neutrality with 10g of baking soda, control the vacuum above -0.095Mpa and carry out steaming at a constant temperature of 50°C to obtain 11g of the product. The moisture detection is 70%, and the meteorological detection only has α-chlorine Dai-α-acetyl-γ-butyrolactone peak shape, thus recovering 3.3 g of α-chloro-α-acetyl-γ-butyrolactone.

Embodiment 2

[0057] (a) 192g of α-acetyl-γ-butyrolactone, 125g of baking soda and 252g of water are put into the reaction equipment, and the temperature is controlled within 18°C, and then 110g of chlorine gas is introduced to react, and after the reaction is finished, it is allowed to stand for stratification to obtain Product α-chloro-α-acetyl-γ-butyrolactone 231.6g and delamination water 377.1g;

[0058] (b) After adding 10 g of sodium thiosulfate to the obtained layered water, adjust it to neutral with 7.1 g of sodium bicarbonate, then control the vacuum to -0.095Mpa and distill water at a constant temperature of 50°C to obtain 20 g of the product, The moisture detection was 62%, and the meteorological detection only had the peak type of α-chloro-α-acetyl-γ-butyrolactone, thus recovering 7.6 g of α-chloro-α-acetyl-γ-butyrolactone.

Embodiment 3

[0060] (a) 192g of α-acetyl-γ-butyrolactone, 125g of baking soda and 252g of water are put into the reaction equipment, and the temperature is controlled within 18°C, and then 110g of chlorine gas is introduced to react, and after the reaction is finished, it is allowed to stand for stratification to obtain Product α-chloro-α-acetyl-γ-butyrolactone 231.5g and delamination water 377.2g;

[0061] (b) Seal the obtained layered water with ultraviolet light for 1 hour, then adjust it to neutral with 9.5g of baking soda, control the vacuum above -0.095Mpa and distill water at a constant temperature of 50°C to obtain 19g of the product, moisture detection It was 47%, and there was only α-chloro-α-acetyl-γ-butyrolactone peak type in meteorological detection, thus 10.07 g of α-chloro-α-acetyl-γ-butyrolactone was recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com