Environment-friendly pervious concrete and preparation method thereof

A permeable concrete, environmental protection technology, applied in the field of concrete materials, can solve the problems of long rigid polypropylene fiber, affecting the stability of concrete, affecting the compatibility of cement, etc., to enhance compatibility, avoid comprehensive performance and performance Poor stability and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

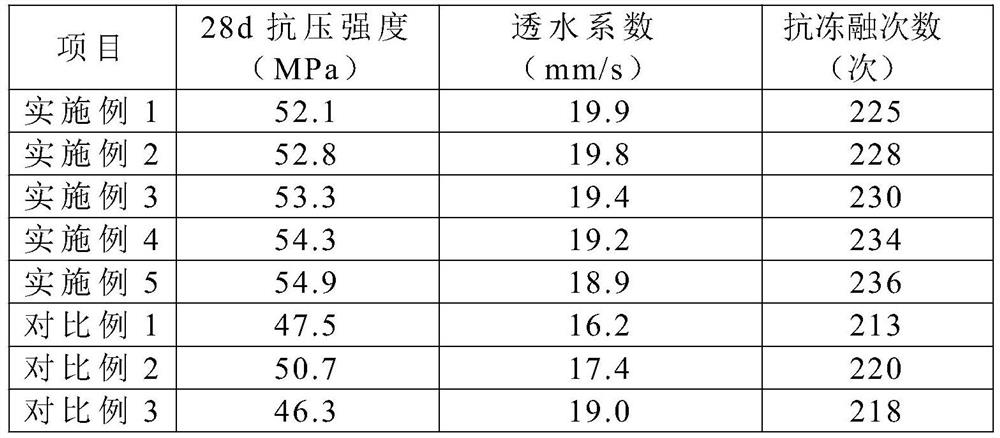

Examples

Embodiment 1

[0030] An environment-friendly permeable concrete, characterized in that it is made from the following raw materials in parts by weight: 15 parts of cement, 60 parts of coarse aggregate, 5 parts of hydrophilic nitrogen-doped carbon nanofiber dense network, waste porous ceramsite 10 parts, 1 part of alkoxy-modified 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane, 1 part of fluorenylsulfonate water reducer, 8 parts of water.

[0031] The coarse aggregate is crushed stone; the particle size of the coarse aggregate is 5 mm; the specification of the waste porous ceramsite is K1, provided by Guangzhou Institute of Energy Research, Chinese Academy of Sciences.

[0032] The preparation method of the alkoxy-modified 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane comprises: silane coupling agent KH-560, 2,2-bis(3-amino -4-Hydroxyphenyl)hexafluoropropane was added to the organic solvent, stirred and reacted at 70°C for 4 hours, and then the solvent was removed by rotary evaporation...

Embodiment 2

[0036] An environmentally friendly permeable concrete, characterized in that it is made from the following raw materials in parts by weight: 17 parts of cement, 65 parts of coarse aggregate, 6 parts of hydrophilic nitrogen-doped carbon nanofiber dense network, waste porous ceramsite 12 parts, 1.5 parts of alkoxy-modified 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane, 1.2 parts of fluorenylsulfonate water reducer, and 10 parts of water.

[0037] The coarse aggregate is crushed pebbles; the particle size of the coarse aggregate is 7mm; the specification of the waste porous ceramsite is K2, which is provided by the Guangzhou Energy Research Institute of the Chinese Academy of Sciences.

[0038] The preparation method of the alkoxy-modified 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane comprises: silane coupling agent KH-560, 2,2-bis(3-amino -4-Hydroxyphenyl)hexafluoropropane was added to the organic solvent, stirred and reacted at 73°C for 4.5 hours, and then the solvent...

Embodiment 3

[0042] An environmentally friendly permeable concrete is characterized in that it is made of the following raw materials in parts by weight: 17 parts of cement, 70 parts of coarse aggregate, 8 parts of hydrophilic nitrogen-doped carbon nanofiber dense network, waste porous ceramsite 15 parts, 2 parts of alkoxy-modified 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane, 1.5 parts of fluorenylsulfonate water reducer, and 11 parts of water.

[0043] The coarse aggregate is regenerated construction waste material; the regenerated construction waste material is sorted waste concrete; the particle size of the coarse aggregate is 8 mm. The specification of the waste porous ceramsite is K3, provided by Guangzhou Institute of Energy Research, Chinese Academy of Sciences.

[0044] The preparation method of the alkoxy-modified 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane comprises: silane coupling agent KH-560, 2,2-bis(3-amino -4-Hydroxyphenyl)hexafluoropropane was added to the or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com