Prefabricated concrete component production line

A prefabricated component and production line technology, applied in the field of production line and concrete prefabricated component production line, can solve the problems of single product type, large production line footprint, poor flexibility, etc., and achieve flexible production, small footprint, and complete supporting equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

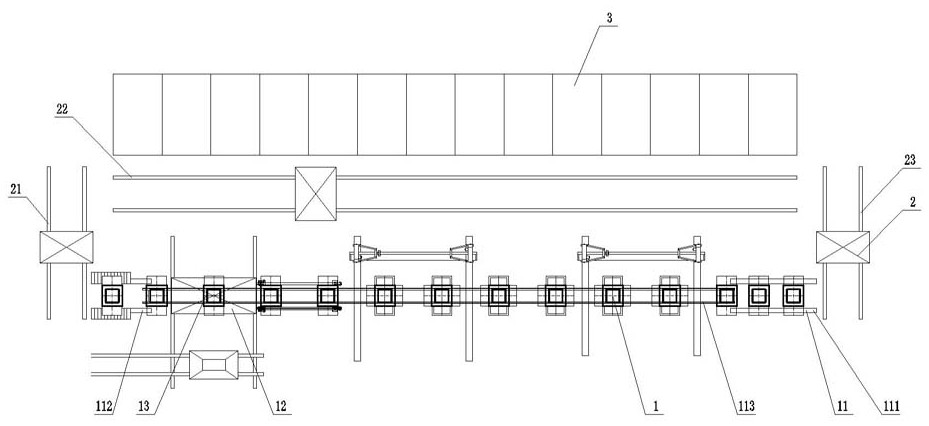

[0035] Such as figure 1 and 3 As shown, a concrete prefabricated component production line includes an operation system 1, a ferry system 2 and a maintenance system 3, and materials flow between the operation system 1 and the maintenance system 3 through the ferry system 2; it is characterized in that: the operation system 1 includes Conveyor system 11, material distribution system 12, vibration system 13;

[0036] The conveying system 11 comprises a front-end chain conveying system 111, an end chain conveying system 112 and a step conveying system 113, and the front-end chain conveying system 111 and the end chain conveying system 112 have the same structure; the step conveying system 113 is respectively interlaced with the front chain conveyor system 111 and the end chain conveyor system 112 in the conveying direction;

[0037] The stepping conveying system 113 includes a lifting mechanism 1131 and a transmission bracket 1132;

[0038] The front-end chain transmission sys...

Embodiment 2

[0051] Such as figure 2 and 3 As shown, a concrete prefabricated component production line includes an operation system 1, a ferry system 2 and a maintenance system 3, and materials flow between the operation system 1 and the maintenance system 3 through the ferry system 2; it is characterized in that: the operation system 1 includes Conveyor system 11, material distribution system 12, vibration system 13;

[0052] The conveying system 11 comprises a front-end chain conveying system 111, an end chain conveying system 112 and a step conveying system 113, and the front-end chain conveying system 111 and the end chain conveying system 112 have the same structure; the step conveying system 113 is respectively interlaced with the front chain conveyor system 111 and the end chain conveyor system 112 in the conveying direction;

[0053] The stepping conveying system 113 includes a lifting mechanism 1131 and a transmission bracket 1132;

[0054] The front-end chain transmission sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com