High-corrosion-resistance super duplex stainless steel pipe machining device and machining process thereof

A technology of duplex stainless steel and processing device, applied in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc. Easy to adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

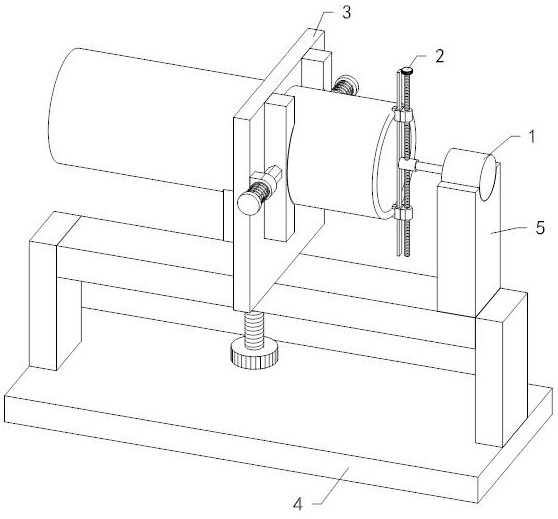

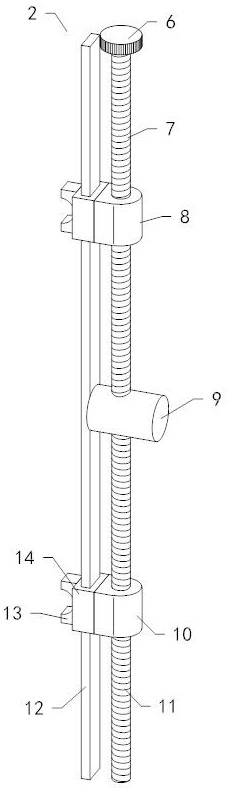

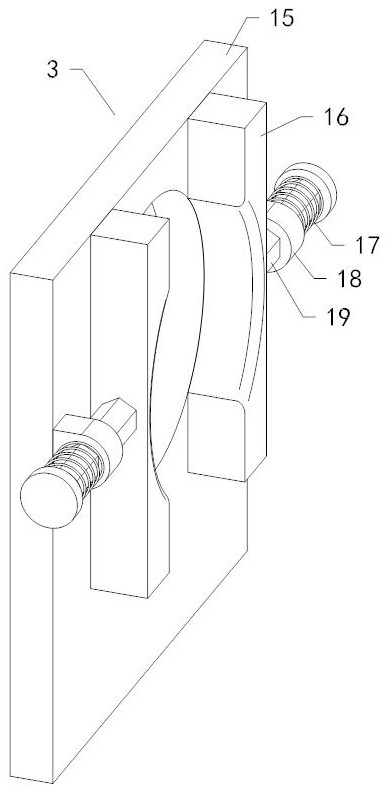

[0030] refer to Figure 1 to Figure 4 , the high corrosion-resistant super duplex stainless steel pipe processing device and its processing technology involved in the present invention, the process steps are:

[0031] Step 1; clamping: clamp the stainless steel on the clamp 3;

[0032] Step 2: Coarse grinding: use a hard grinding block 13 to rotate along the cut of the stainless steel pipe for preliminary grinding;

[0033] Step 3: Blocking: Cover the polished mouth of the stainless steel tube with gauze;

[0034] Step 4: Fine grinding: start the device and then flash and rotate, and finely grind the grinding port of the stainless steel tube through gauze;

[0035] Step 5: Take the tube: remove the stainless steel tube from the clamp 3 .

[0036] In the step 3, the gauze is kept as loose as possible, so that the gauze polishing blocks 13 are embedded together.

[0037] The above-mentioned processing technology is based on the high-corrosion-resistant super duplex stainless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com