An operation method of a low-load flexible operation combined heat and power turbogenerator set

A turbogenerator unit and combined heat and power generation technology, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of damage to the final stage blades in the low-pressure cylinder, decline and increase of thermoelectric conversion efficiency, etc., and achieve more efficient operation. Facilitating the utilization of waste heat from exhaust steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

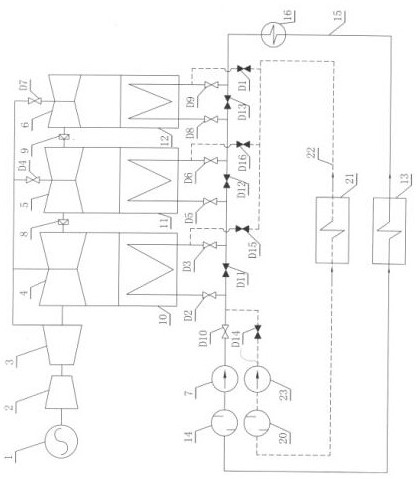

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

[0016] An operating method of a combined heat and power turbogenerator set that operates flexibly at low loads, comprising a generator 1, a high-pressure cylinder 2, a medium-pressure cylinder 3, a large and low-pressure cylinder 4, a medium- and low-pressure cylinder 5, a small and low-pressure cylinder 6, and a first clutch 8. The second clutch 9, the condenser circulating cooling waterway 22 and the heating network circulating waterway 15, the condenser circulating cooling waterway filter 20, the condenser circulating water cooling waterway 22 are arranged in series Equipment 21, circulating water pump 23 and fourteenth isolating valve D14, heat network circulating water pump 7, heat user 13, heating network circulating water filter 14, heating network water high temperature heater 16 are arranged in series in the heating network circulating waterway 15 and the tenth isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com