V-Ni3FeN/Ni-coated N-GTs full-electrolysis water electric catalyst constructed based on doping and heterojunction strategies

A technology of v-ni3fen and catalyst, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of high cost, low storage, hindering large-scale commercial application, etc., to improve activity, improve hydrogen evolution and oxygen evolution performance, excellent The effect of electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

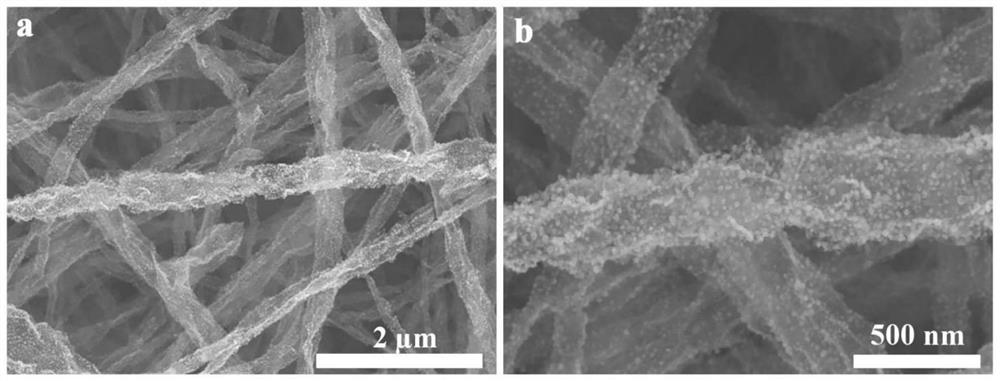

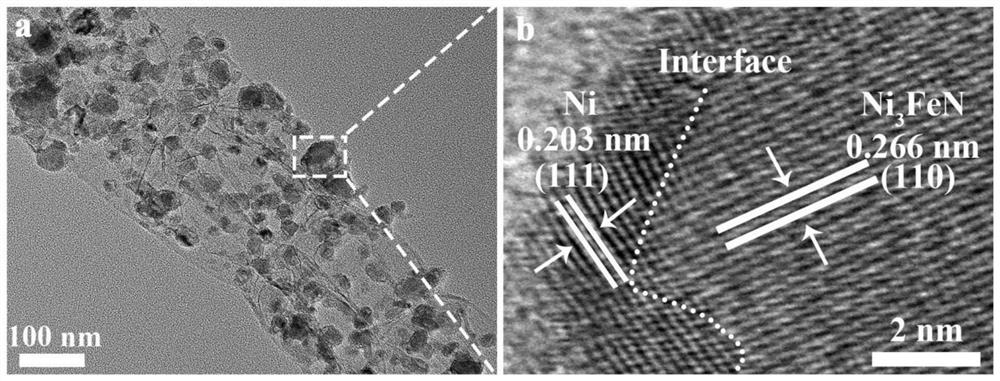

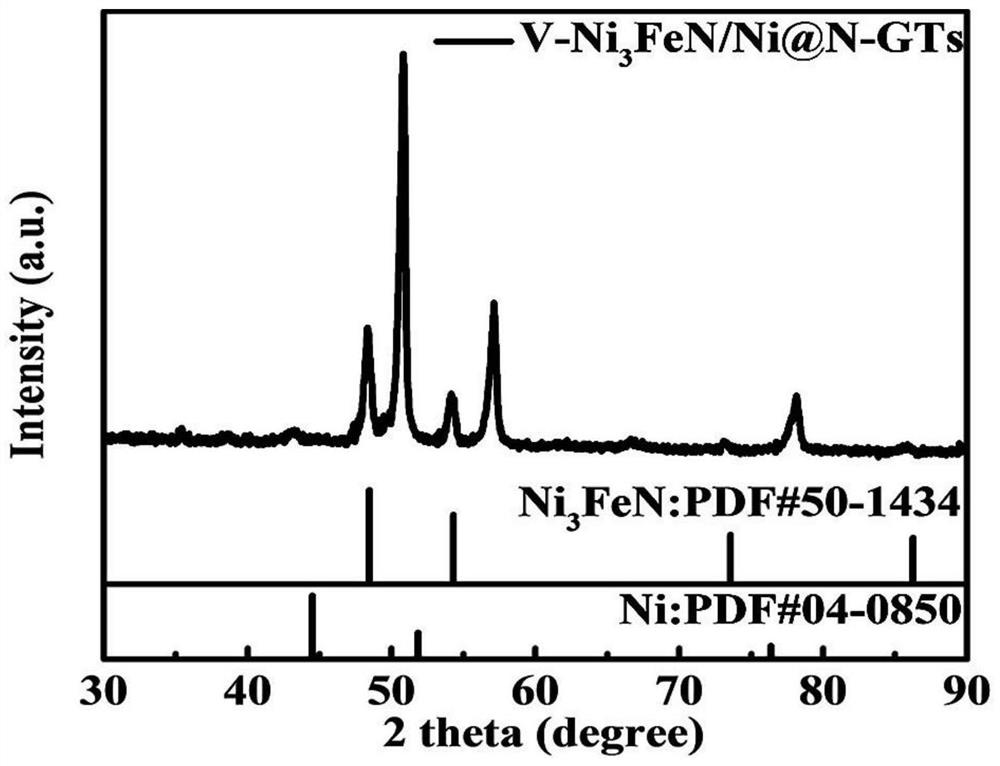

[0022] The total electrocatalyst V-Ni for water splitting described in this embodiment 3 The preparation method of FeN / Ni@N-GTs comprises the following steps:

[0023] (1) Weigh 0.108mmol Na 3 VO 4 , 4 mmol NH 4 F and 8mmol CH 4 N 2 O was dissolved in 70mL of distilled water, and 2mmol of nickel nitrate and iron nitrate were weighed at a molar ratio of 5:1, dissolved in the above solution, and transferred to the reaction kettle (100ml), and the nitrogen-doped graphite grown on the graphite sheet was Immerse the graphene tube in the reactor for hydrothermal reaction, the reaction temperature is 120°C, the reaction time is 6h, then wash and dry the product to obtain the V-doped NiFe precursor supported on the nitrogen-doped graphene tube;

[0024] (2) Put the product of step (1) into a tube furnace, heat it up to 470°C at 5°C / min in an Ar atmosphere, turn off the argon gas, and at this temperature, feed ammonia gas for 2h, and cool to room temperature, Obtain the full spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com