Preparation method and application of efficient heat-conducting UV-LED printing ink

A UV-LED, high-efficiency technology, used in inks, applications, household appliances, etc., can solve problems such as poor compatibility of micenes, and achieve the effects of preventing agglomeration, improving dispersion, and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

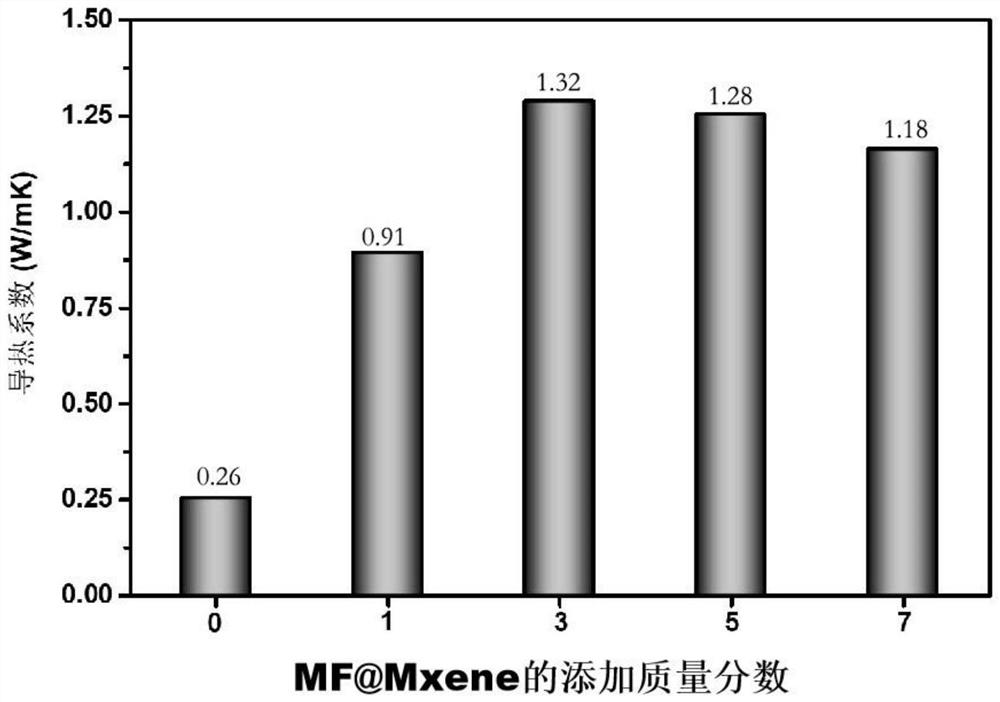

Embodiment 1

[0044] A kind of preparation method of efficient heat conduction UV-LED printing ink, comprises the following steps:

[0045] (1) Take 6g of melamine and add 60mL of deionized water, stir at a speed of 300r / min; then add 14mL (37%) of formaldehyde solution dropwise, and use the newly configured Na 2 CO 3 (10%) solution to adjust the pH to 9, heat up to 80°C, and continue to stir for 20 minutes to obtain a melamine-formaldehyde prepolymer;

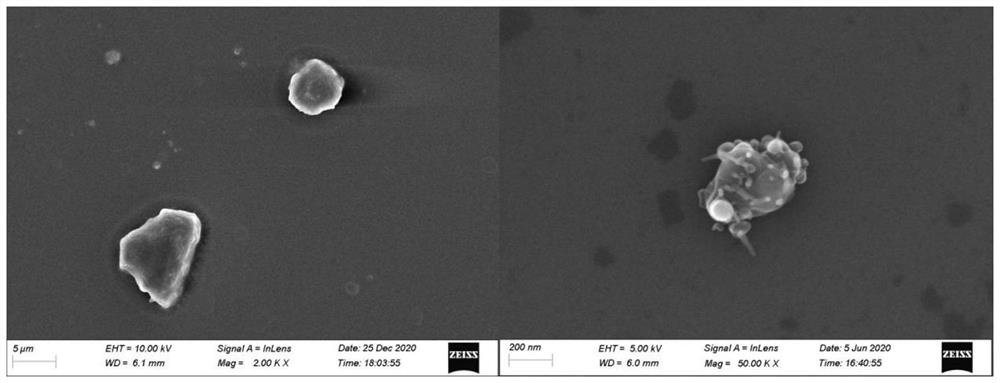

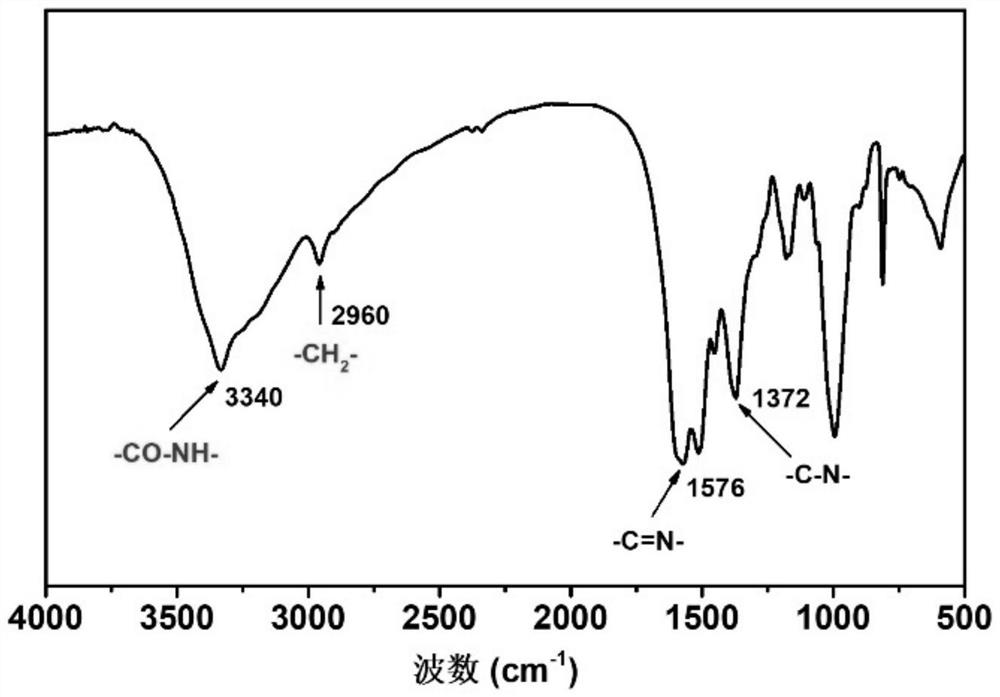

[0046](2) Add 1.0g of lithium fluoride to 150mL of HCl, stir for 5 minutes, then add 2.0g of aluminum carbide powder, stir and react at 30°C for 8 hours, wash with deionized water until the pH is 5.5, and place in ultrasonic cleaning Ultrasonic peeling in the device was performed for 10 minutes, and the power was set to 200w. After the stripping is completed, the reaction solution is centrifuged at 2000r / min for 10 minutes, and the lower layer of sediment is taken out and placed in a drying oven to dry to obtain Mxene;

[0047] (3) Take ...

Embodiment 2

[0050] A kind of preparation method of efficient heat conduction UV-LED printing ink, comprises the following steps:

[0051] (1) Take 4g of melamine and add 40mL of deionized water, stir at a speed of 200r / min; then add 7.2mL (37%) of formaldehyde solution dropwise, and use the newly configured Na 2 CO 3 (10%) solution adjusts pH to 8, heats up to 70 ℃, continues to stir for 30 minutes, obtains melamine-formaldehyde prepolymer;

[0052] (2) Add 1.5g of lithium fluoride to 200mL of HCl, stir for 10 minutes, then add 2.5g of aluminum carbide powder, stir and react at 40°C for 10 hours, wash with deionized water until the pH is 6, and place in ultrasonic cleaning Ultrasonic peeling in the device was performed for 15 minutes, and the power was set to 200w. After the stripping is completed, the reaction solution is centrifuged at 2500r / min for 15 minutes, and the lower layer of sediment is taken out and placed in a drying oven to dry to obtain Mxene;

[0053] (3) Take 1.5g of M...

Embodiment 3

[0056] A kind of preparation method of efficient heat conduction UV-LED printing ink, comprises the following steps:

[0057] (1) Take 3g of melamine and add 35mL of deionized water, stir at a speed of 250r / min; then add 7.5mL (37%) of formaldehyde solution dropwise, and use the newly configured Na 2 CO 3 (10%) solution adjusts pH to 10, heats up to 60 ℃, continues to stir for 40 minutes, obtains melamine-formaldehyde prepolymer;

[0058] (2) Add 2.0g of lithium fluoride to 400mL of HCl, stir for 15 minutes, then add 5g of aluminum carbide powder, stir and react at 40°C for 15 hours, wash with deionized water until the pH is 7, and place in an ultrasonic cleaner Medium ultrasonic peeling for 20 minutes, the power is set to 300w. After the stripping is completed, the reaction solution is centrifuged at 3000r / min for 10 minutes, and the lower layer of sediment is taken out and placed in a drying oven to dry to obtain Mxene;

[0059] (3) Take 4g of Mxene and add 450mL of N-met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com