Porous silicon resin and lightweight flexible flame-retardant composite material

A technology of porous silicon and resin, which is applied in the field of nanoporous materials, can solve the problems that thermal protection materials cannot meet the requirements of flame retardancy, ultra-light weight, high strength, easy combustion, ablation and peeling, and no flame retardancy. Thermal insulation application value, low density and thermal conductivity, effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

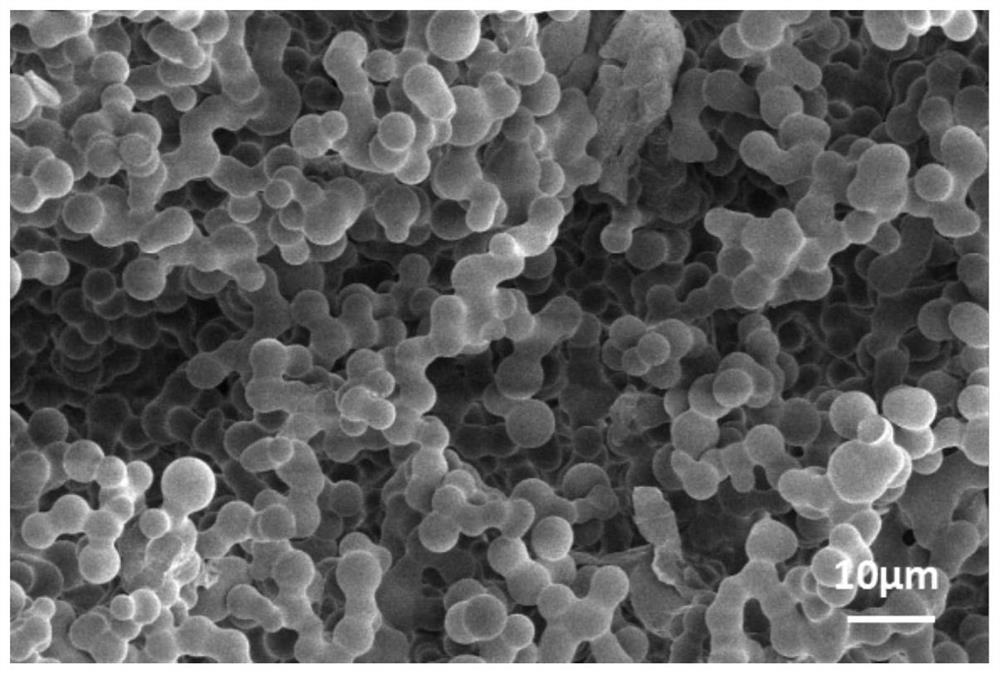

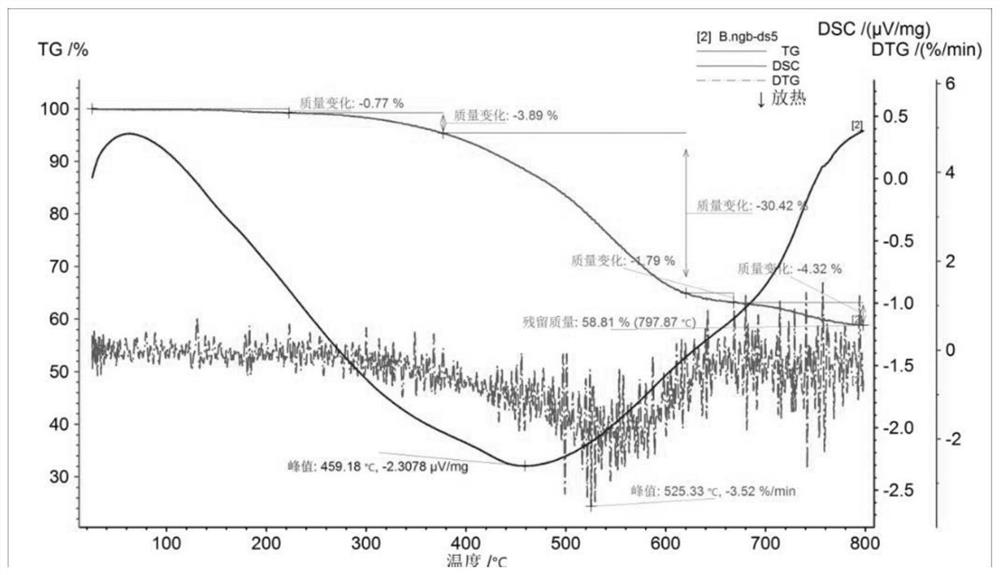

[0054] The specific embodiment of the present invention provides a kind of porous silicone resin, its preparation method, comprises:

[0055] (1) Preparation of porous silicone resin precursor solution: first add flame retardant and surfactant to the solvent and stir for 10-20 minutes, then add siloxane monomer, catalyst and auxiliary agent, and then vigorously stir for 30-300 minutes, Obtain porous silicone resin precursor solution;

[0056] (2) Curing process: under sealed conditions, the above-mentioned porous silicone resin precursor solution is solidified at 60-120° C. for 12-72 hours, and then cooled to room temperature to obtain a porous silicone resin gel;

[0057] (3) Drying process: the wet porous silicone resin gel in step (2) is first left to air at room temperature for more than 24 hours, and then dried in an oven at 60-80°C for more than 48 hours until the weight no longer decreases, and a porous silicone gel is obtained. Silicone.

[0058] Another embodiment o...

Embodiment 1

[0071] Embodiment 1: porous silicone resin, its preparation method comprises the steps:

[0072] (1) Preparation of porous silicone resin precursor solution: first weigh 1.5g of magnesium hydroxide, 0.3g of cetyltrimethylammonium chloride and 8.0g of deionized water, put them in a beaker, and stir for 5-10 Minutes to form a transparent solution; then weigh 5.0g methyltriethoxysilane, 2.0g dimethyldiethoxysilane, 1.0g phenyltriethoxysilane, stir vigorously for 30-40 minutes; add dropwise Stir 5ml of 0.1mol / L hydrochloric acid solution until the pH is about 5; the molar ratio of the added HCl to the total siloxane monomer is about 1:9. Continue to stir, add 0.1mol / L ammonia solution after hydrolysis for 60 minutes, adjust the pH of the solution to about 7.0, and obtain the porous silicone resin precursor solution;

[0073] (2) Curing process: transfer the above-mentioned porous silicone resin precursor solution to a PP tube for sealing, then place it in an oven at 60°C for curi...

Embodiment 2

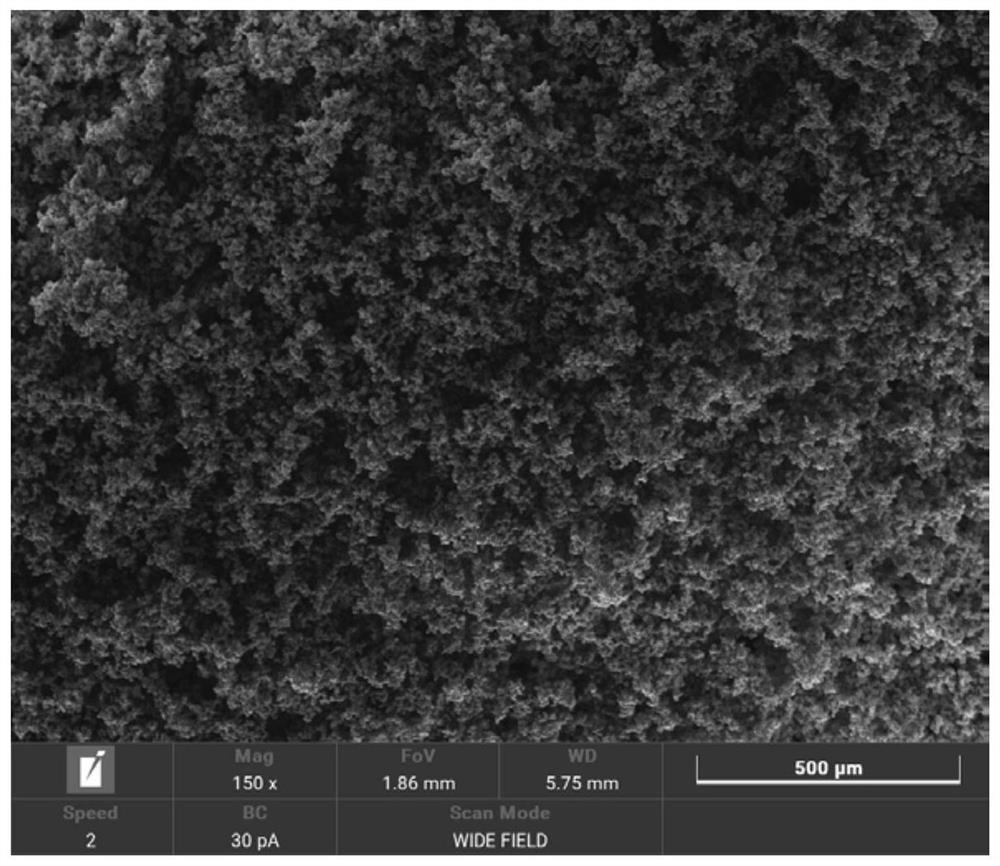

[0076] Embodiment 2: lightweight flexible flame-retardant composite material, its preparation method comprises the following steps:

[0077] (1) Preparation of porous silicone resin precursor solution: first 5.0g magnesium hydroxide, 4g cetyltrimethylammonium chloride were added to a beaker of 50g deionized water, stirred for 10 minutes to form a uniform transparent solution, Then add 30g methyltrimethoxysilane, 20g vinyltriethoxysilane, 7.0g p-methylphenyltrimethoxysilane to the beaker, stir vigorously, then add 0.1mol / L glacial acetic acid dropwise while stirring Solution 100ml, after dropwise addition within 30min, continue to stir for 30min, finally add 20g of urea, continue to stir for 10min to obtain a uniform porous silicone resin precursor solution;

[0078] (2) Impregnation process: put a lightweight flexible quartz fiber non-woven fabric (flexible non-woven three-dimensional fabric) with a size of 10cm×10cm×0.5cm, with a mass of 7.55g, into a steel mold of 10cm×10cm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com