Green production process of nicosulfuron intermediate nicotinamide and sulfonamide

A technology for nicotinamide and nicosulfuron is applied in the field of preparation of herbicide intermediates, which can solve problems such as water body eutrophication and environmental pollution, and achieve the effects of low cost, reduced production cost, and reduced processing difficulty and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

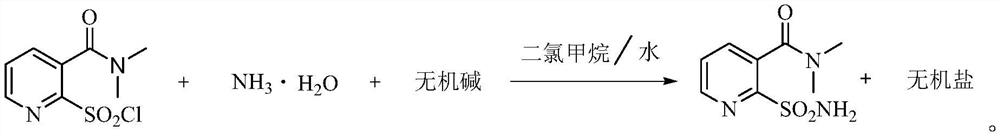

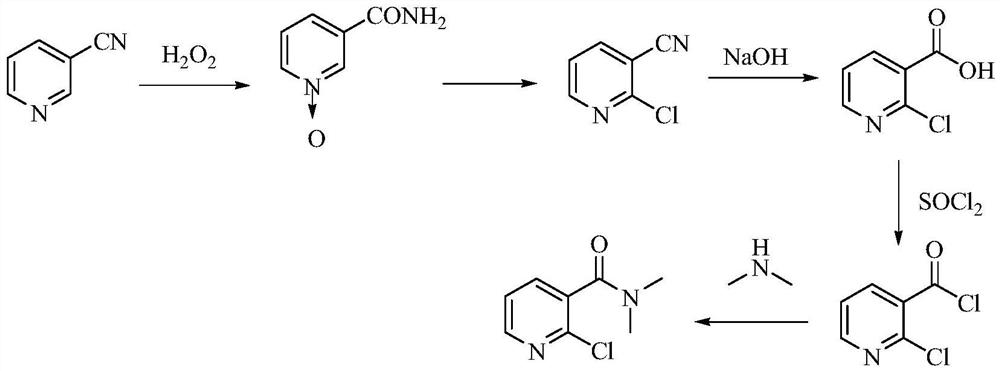

Method used

Image

Examples

Embodiment 1

[0054] 1) Preparation of nicotinamide:

[0055] Add 90g of dichloroethane, 11.3g (0.1mol) of 40% dimethylamine aqueous solution, 4.8g (0.12mol) of NaOH and 16.2g of water into the flask, cool down to below 0°C, and start to drop the prepared 66.5 g nicotinyl chloride solution (0.098mol), the dropwise addition temperature is controlled at -10°C to 0°C. At the end of the dropwise addition, keep warm for 1 hour, separate layers, and desolventize the organic layer under negative pressure to obtain 18.3 g of nicotinamide with a content of 95.8% and a yield of 96.9%. The content of ammonia nitrogen in the amination wastewater is 2218 mg / L.

[0056] 2) Preparation of 2-(sulfonyl chloride)-N,N-dimethyl-3-pyridinecarboxamide

[0057] Add nicotinamide, sulfur, sodium sulfide and water into the flask, raise the temperature to 110-120°C and keep it warm for 6h. After the reaction, adjust the pH to 2-3 with hydrochloric acid, and then filter; add a certain amount of dichloromethane to th...

Embodiment 2

[0062] 1) Preparation of nicotinamide

[0063] Add 82g of dichloroethane, 13.5g (0.12mol) of 40% dimethylamine aqueous solution, 4.8g (0.12mol) of NaOH and 16.2g of water into the flask, lower the temperature to below 0°C, and start to drop the prepared 66.5 g nicotinyl chloride solution (0.098mol), the dropwise addition temperature is controlled at -10°C to 0°C. At the end of the dropping, keep warm for 1 hour, separate layers, and desolventize the organic layer under negative pressure to obtain 18.36 g of nicotinamide with a content of 96.3% and a yield of 97.8%. The content of ammonia nitrogen in the amination wastewater is 4742 mg / L.

[0064] 2) Preparation of 2-(sulfonyl chloride)-N,N-dimethyl-3-pyridinecarboxamide

[0065] Add nicotinamide, sulfur, sodium sulfide and water into the flask, raise the temperature to 110-120°C and keep it warm for 6h. After the reaction, adjust the pH to 2-3 with hydrochloric acid, and then filter; add a certain amount of dichloromethane t...

Embodiment 3

[0069] 1) Preparation of nicotinamide

[0070] Add 82g of dichloroethane, 12.38g (0.11mol) of 40% dimethylamine aqueous solution, and 17.33g (0.13mol) of 30% sodium hydroxide aqueous solution into the flask, cool down to below 0°C, and start to drop the prepared 66.5g of nicotinyl chloride solution (0.098mol), the dropwise addition temperature is controlled at -10°C to 0°C. At the end of the dropping, keep warm for 1 hour, separate layers, and desolventize the organic layer under negative pressure to obtain 18.25 g of nicotinamide with a content of 96.4% and a yield of 97.3%. The content of ammonia nitrogen in the amination wastewater is 3576 mg / L.

[0071] 2) Preparation of 2-(sulfonyl chloride)-N,N-dimethyl-3-pyridinecarboxamide

[0072] Add nicotinamide, sulfur, sodium sulfide and water into the flask, raise the temperature to 110-120°C and keep it warm for 6h. After the reaction, adjust the pH to 2-3 with hydrochloric acid, and then filter; add a certain amount of dichlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com