Novel gear chamber oil conveying structure

A technology for gear chambers and oil delivery, which is applied in gear lubrication/cooling, belts/chains/gears, transmission parts, etc., and can solve problems such as difficulty in ensuring the cleanliness of the oil passage, uncompact and compact shape, and difficulty in heat dissipation and chip removal. , to achieve the effects of preventing high-pressure lubricating oil leakage, resisting high vibration, reducing cost and processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

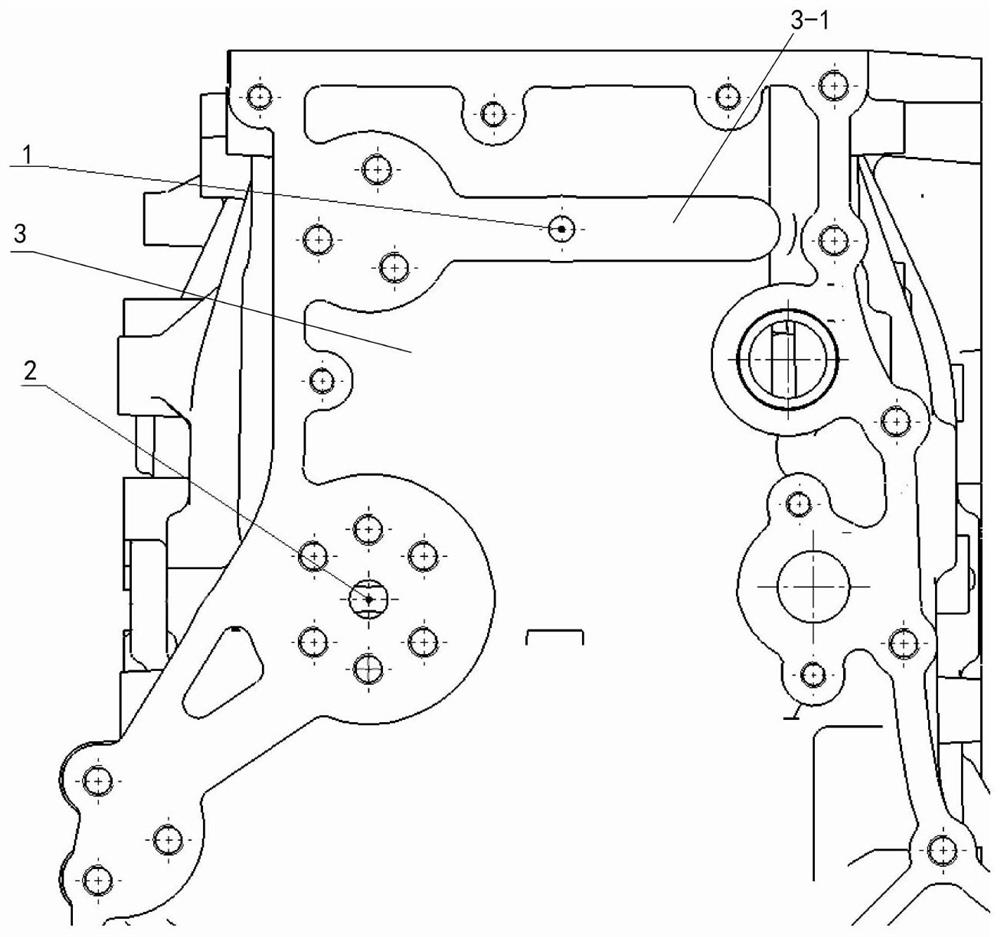

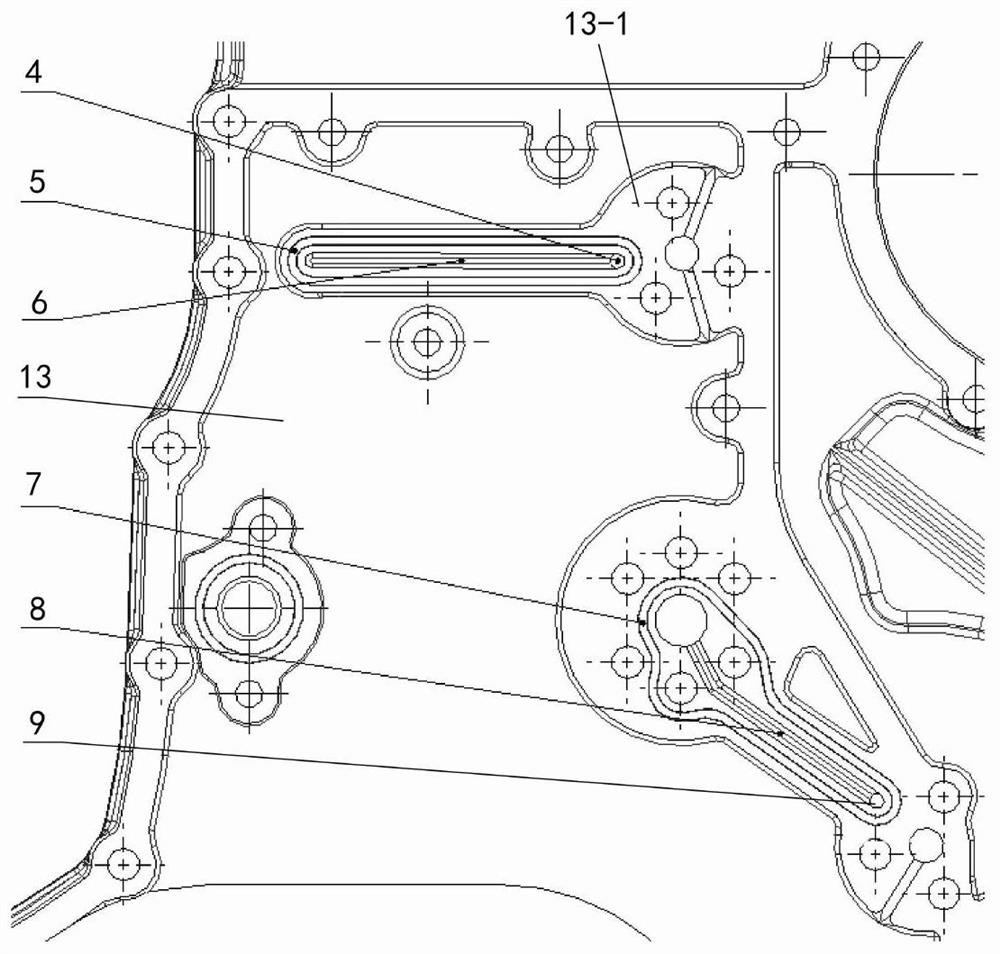

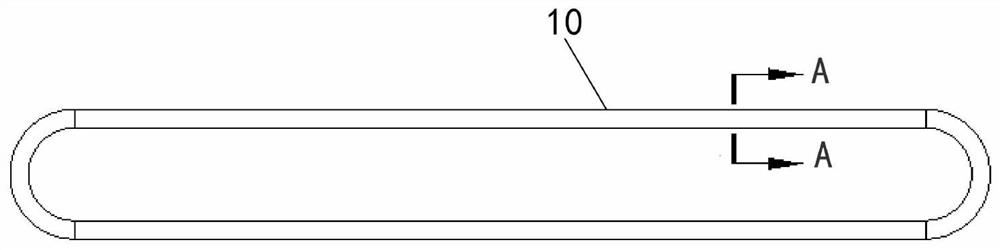

[0021] Such as Figure 1~5 As shown, a new gear chamber oil delivery structure includes a cylinder block 3, a gear chamber 13 and a crimped washer; grooves are machined or directly cast on the end surface of the gear chamber 13 and the cylinder block 3, forming an opening. Type oil passages 6, 8; the open oil passages 6, 8 can form a closed oil passage after the gear chamber 13 and the cylinder block 3 are installed and fitted together; the gear chamber 13 and the cylinder block The open oil passages of 3 also have oil output ports 4, 9 and oil input ports 1, 2 correspondingly; when in use, the machine oil flows into the open oil passages 6, 8 from the oil input ports 1, 2 and flows from the oil respectively. The output ports 4, 9 flow into the required lubrication parts. A ring of sealing grooves 5 and 7 are correspondingly provided on the periphery of the open oil passage, and the crimped gaskets are distributed in the sealing grooves. In order to improve the stability, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com