Silver nanotube network film based on electromagnetic interference shielding and preparation method thereof

A technology of electromagnetic interference shielding and silver nanotubes, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of mechanical performance impact, difficulty in large-scale production, etc., and reduce the intensity of light and reflective interference, avoiding the effect of visual impairment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

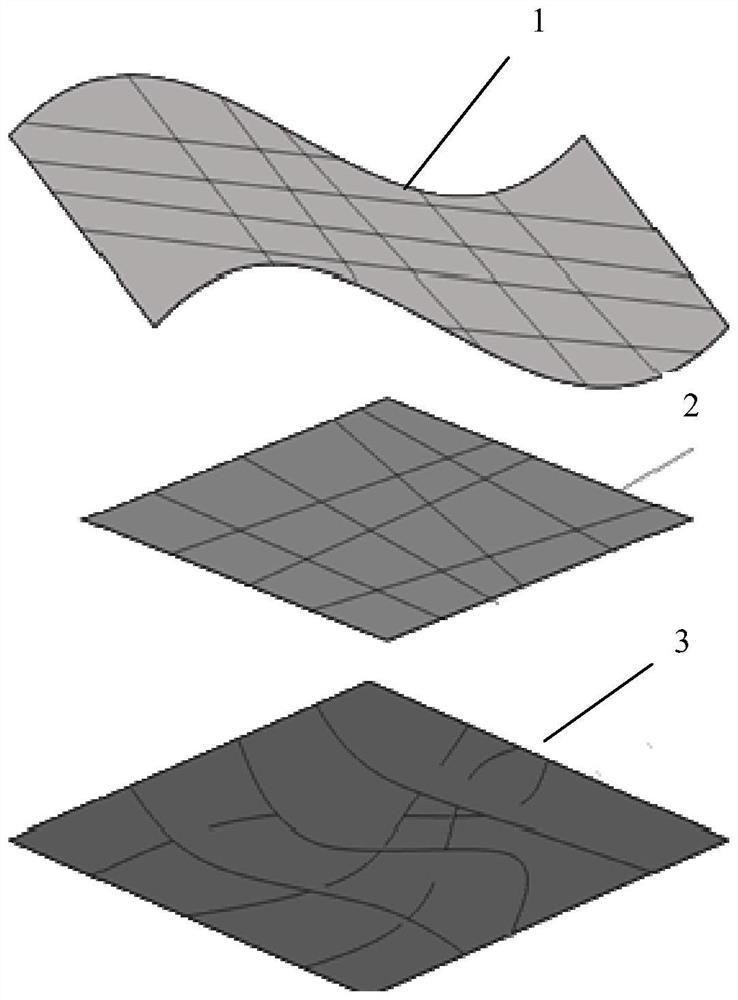

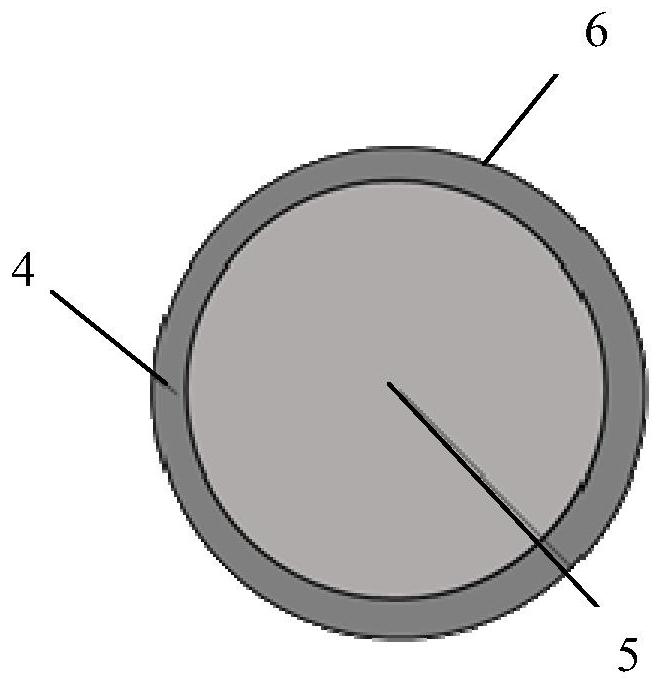

[0036] (1) The PVA solution with a mass fraction of 10% was stirred and heated at 65° C. and 1300 rpm for 12 hours, and the PVA solution was cooled to room temperature and injected into an electrospinning device. The spinneret is connected to the positive pole of the high-voltage power supply, the working voltage is maintained at 12kV, and the working distance between the spinning nozzle and the receiving ring should be kept at 12 cm. Prepare PVA cores 5 arranged in a line to obtain a PVA nanofiber membrane. The electrospinning time directly determines the mass density of the AgNTs network, thereby affecting the EMI SE and transmittance.

[0037] (2) Place the PVA nanofiber film obtained in step (1) in an 80% RH oven at 65°C for 550s to dissolve the binding part of the PVA nanofiber, then heat it at 65°C for 550s in a vacuum and non-humid environment to remove moisture, and make the nanofiber The fibers are perfectly interconnected.

[0038] (3) Prepare the outer Ag layer 4 ...

Embodiment 2

[0041] (1) The PVA solution with a mass fraction of 12% was stirred and heated at 75° C. and 1500 rpm for 21 hours, and the PVA solution was cooled to room temperature and injected into an electrospinning device. The spinneret is connected to the positive pole of the high-voltage power supply, the working voltage is maintained at 15kV, and the working distance between the spinning nozzle and the receiving ring should be kept at 15 cm. Prepare PVA cores 5 arranged in a line to obtain a PVA nanofiber membrane. The electrospinning time directly determines the mass density of the AgNTs network, thereby affecting the EMI SE and transmittance.

[0042] (2) Place the PVA nanofiber film obtained in step (1) in an 85% RH oven at 75°C for 650s to dissolve the binding part of the PVA nanofiber, then heat it at 75°C for 650s in a vacuum and non-humid environment to remove moisture, and make the nanofiber The fibers are perfectly interconnected.

[0043] (3) Prepare the outer Ag layer 4 ...

Embodiment 3

[0046] (1) The PVA solution with a mass fraction of 15% was stirred and heated at 70° C. and 1400 rpm for 24 hours, and the PVA solution was cooled to room temperature and injected into an electrospinning device. The spinneret is connected to the positive pole of the high-voltage power supply, the working voltage is maintained at 18kV, and the working distance between the spinning nozzle and the receiving ring should be kept at 18 cm. Prepare PVA cores 5 arranged in a line to obtain a PVA nanofiber membrane. The electrospinning time directly determines the mass density of the AgNTs network, thereby affecting the EMI SE and transmittance.

[0047] (2) Place the PVA nanofiber film obtained in step (1) in a 90% RH oven at 70°C for 600s to dissolve the binding part of the PVA nanofiber, then heat it at 70°C for 600s in a vacuum and non-humid environment to remove moisture, and make the nanofiber The fibers are perfectly interconnected.

[0048] (3) Prepare the outer Ag layer 4 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com